Ultrasonic Transducer Characterization Using VibroMicro

This case study showcases how the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer enables high-fidelity, non-contact vibration measurement for ultrasonic transducer testing. With nanometer precision and wide bandwidth, it reveals transient dynamics such as ring-up, resonance, and ring-down behavior in real time.

Non-Contact Natural Frequency Testing with VibroMicro

This solution combines non-contact excitation and high-resolution laser vibrometry to form a fully integrated frequency testing platform. By eliminating contact interference, the VibroMicro system accurately measures natural frequencies and mode shapes in delicate or high-precision components—from ultrasonic blades to MEMS structures.

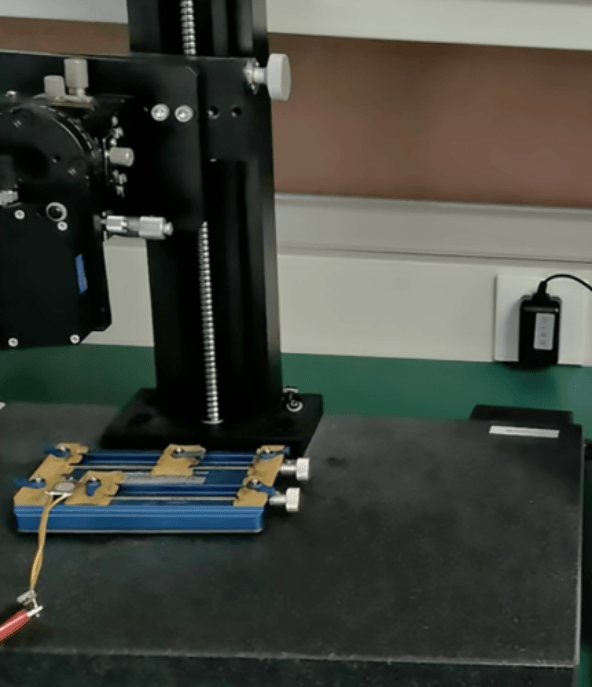

Solder Joint Virtual Welding Detection with VibroMicro

This application introduces a non-destructive method for identifying virtual solder joints using the Dynatronic VibroMicro VM-S-100. By analyzing vibration signatures under controlled excitation, the system detects micro-defects and incomplete bonds with nanometer precision—enhancing quality assurance in automotive, aerospace, and consumer electronics manufacturing.

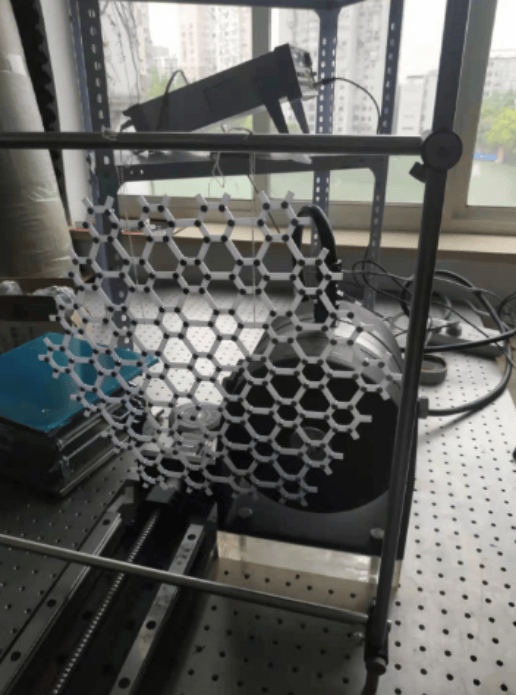

VibroMicro Nodal Vibration Measurement of a Graphene Model

This technical application demonstrates how the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer enables automated, high-resolution vibration testing of a macroscopic graphene molecular structure model—offering non-contact, high-efficiency, and high-precision insights into wave propagation, bandgaps, and structural defects.

Thermal Expansion Measurement at 3000°C Using VibroMicro

This case demonstrates how the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer enables precise, non-contact measurement of transient thermal expansion in metals at temperatures approaching 3000°C. The system’s nanometer-level resolution and stability unlock new insights for aerospace and materials research applications.

Impact Dynamics Testing with VibroMicro Laser Vibrometer

This case highlights how Dynatronic’s VibroMicro Laser Doppler Vibrometer enables high-fidelity, non-contact measurement of impact dynamics in advanced materials. Researchers captured real-time stress wave propagation and damage initiation, providing new insights for aerospace composites, metamaterials, and impact-resistant structures.

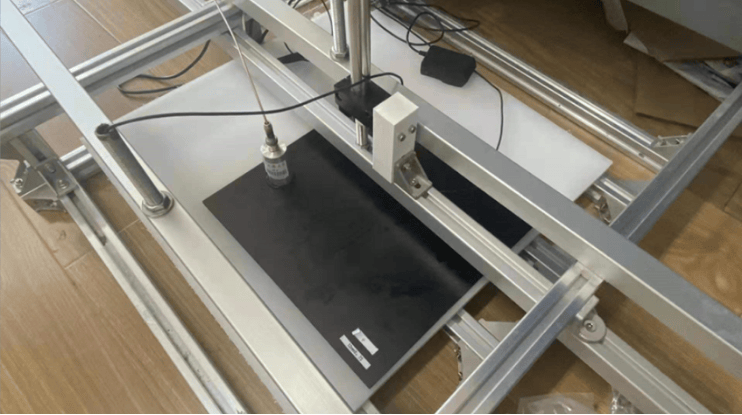

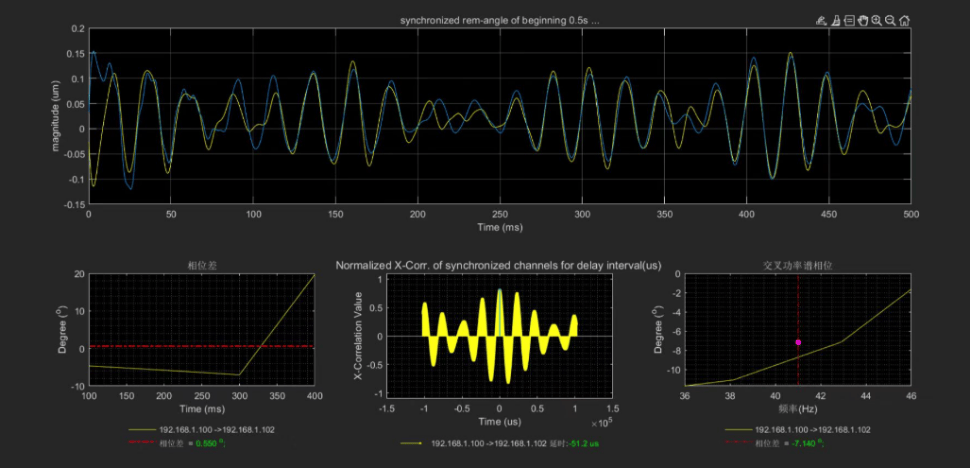

Advanced Acoustic Material Test with Dual-Channel Vibrometry

This case demonstrates how dual-channel synchronized laser vibrometry revolutionizes acoustic material testing in impedance tubes. By visualizing vibration behavior in real time, researchers uncover sound absorption mechanisms, diagnose material weaknesses, and accelerate precision design for aerospace, UAV, and automotive noise control applications.

VibroMicro Case: Bearing Impact Dynamics Measurement

This application case showcases the VibroMicro Laser Doppler Vibrometer in a groundbreaking study on bearing impact dynamics. By capturing transient vibrations at nanosecond precision, the system revealed high-frequency resonances, material response behavior, and impact energy relationships—advancing both research and industrial bearing quality testing standards.

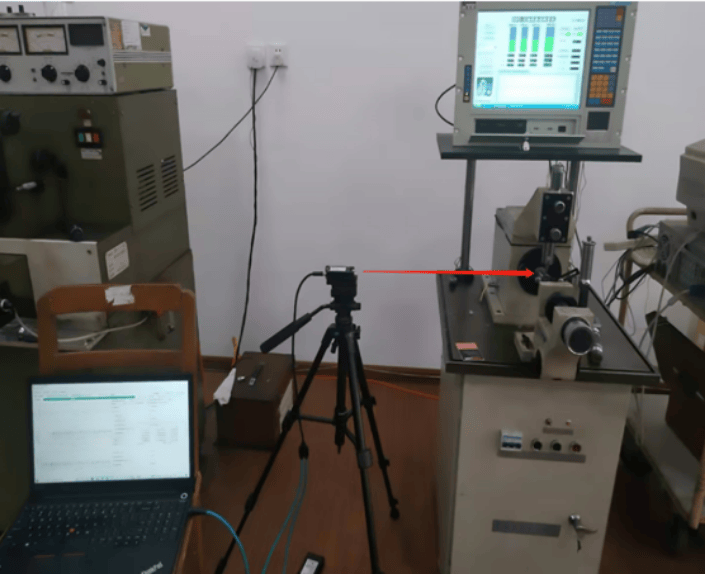

Bearing Quality Inspection Using VibroMicro Vibrometer

This case explores how the VibroMicro Laser Doppler Vibrometer enables non-contact, high-precision bearing quality assessment in industrial environments. Through multiple real-world cases, it demonstrates superior accuracy, repeatability, and efficiency over conventional contact sensors, empowering manufacturers to enhance reliability, reduce maintenance costs, and optimize production quality.

Motor Vibration Analysis Using VibroMicro Vibrometer

This case study demonstrates how the VibroMicro Laser Doppler Vibrometer enables precise, non-contact vibration analysis of motors and rotating machinery. By detecting electrical, mechanical, and structural issues in real time, it supports predictive maintenance, reduces downtime, and improves operational reliability across industrial systems.

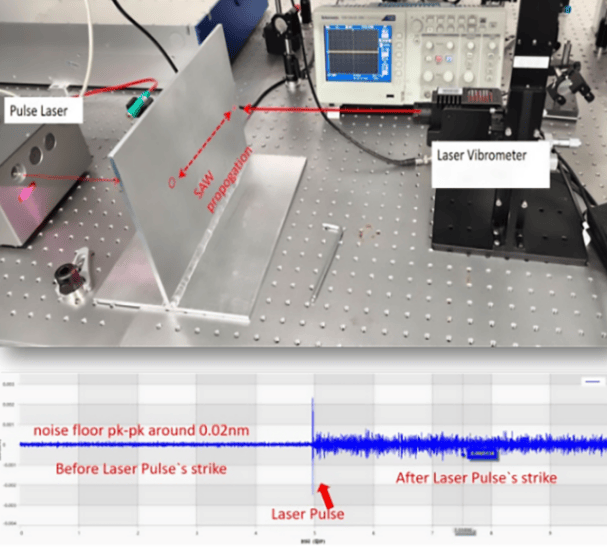

Laser Ultrasonic Testing for Material Characterization

This case demonstrates the use of laser ultrasonic testing with the VibroMicro Laser Doppler Vibrometer for precise, non-contact material characterization. The method enables accurate detection of internal defects, mapping of material properties, and quality control of metal components across aerospace, automotive, and manufacturing applications.

Vibration Characterization of Ultrasonic Surgical Scalpel

Dynatronic’s VibroMicro Laser Doppler Vibrometer enables high-precision vibration analysis of ultrasonic surgical scalpels. Through non-contact measurement, it characterizes longitudinal and transverse motion, ensuring device reliability, manufacturing consistency, and compliance with medical performance standards.

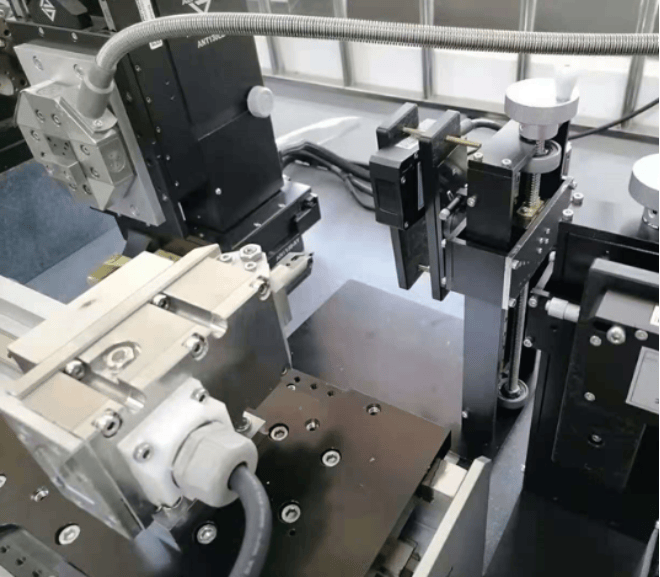

Ultrasonic Tool Tip Vibration Measurement

Dynatronic’s VibroMicro Laser Doppler Vibrometer enables precise, non-contact vibration displacement measurement for ultrasonic machining tool tips. It accurately separates and measures longitudinal and lateral displacements with sub-micron resolution—supporting performance optimization, manufacturing verification, and quality control of ultrasonic-assisted machining tools.

Vibration Analysis of Ultrasonic Scalpel Tips

Dynatronic’s VibroMicro Laser Doppler Vibrometer enables precise, non-contact vibration analysis of ultrasonic scalpel tips. Its high-frequency accuracy and rapid fixture system deliver efficient testing for R&D, quality control, and failure diagnosis—ensuring consistent performance and reliability of medical-grade ultrasonic cutting tools.

Large heading machine rock wall cutting experiment

Large Heading Machine Rock Wall Cutting Experiment

The E BZ 315 road header underwent a rock wall cutting test at the Taiyuan Coal Mining Institute. The RE-846U was used to wirelessly collect and transmit data from the excavator’s operation table, successfully withstanding harsh conditions like vibration, dust, and high temperature to provide valuable data.

Yunnan Machinery Research Institute New Machine Modal Test

Yunnan Machinery Research Institute New Machine Modal Test

Before mass production, a modal test was conducted on the newly developed machine to verify its performance. The test provided data on the machine’s vibration modes, laying the foundation for future optimization of its performance and structure.

Drilling Support Strength Test in Zhongyuan Oilfield

Drilling Support Strength Test in Zhongyuan Oilfield

The WZ-88S system was used for wireless data transmission and collection near the drilling derrick, improving test efficiency by eliminating the need for wiring while ensuring stable signal transmission and reliable results.

Structure performance test of large-scale granulator

Structure Performance Test of Large-Scale Granulator

Yanshan Petrochemical tested key parts of the retrofitted granulator to ensure stable operation. Parameters such as shaft torque, displacement, and vibration were measured, providing reliable data for further equipment improvement and analysis.

Large Crane Load Test – Structural Validation

Large crane load test

In 2011, Changsha Zoomlion Co., Ltd. purchased 19 sets of WZ-88S wireless strain stress test and analysis system and completed the heavy crane load test of Italian CIFA Company.

Modal Vibration Test of Zoomlion Aerial Ladder with DE-944

Modal Test of Zoomlion Aerial Ladder

The DE-944 data acquisition system was used to measure the modal parameters of the Zoomlion aerial ladder by exciting vibrations with water guns. The system collected response signals, which were analyzed to identify the ladder's natural frequency, vibration modes, and damping.