Impact Dynamics Testing with VibroMicro Laser Vibrometer

1. Project Background & Challenges

In the aerospace sector, transient impact events pose a core threat to structural safety. Examples include impact loads during aircraft takeoff/landing, accidental collisions of UAVs in complex environments, and space debris impacts on satellites. To address these challenges, researchers are developing new generations of high-performance materials (e.g., toughened composites, functionally graded materials, bio-inspired structural materials).

However, characterizing the impact dynamics performance of these new materials presents significant difficulties:

Risk of Data Distortion: Traditional contact sensors (e.g., accelerometers) have a mass-loading effect, which can significantly alter the dynamic characteristics of lightweight or small specimens, leading to distorted measurement results.

Limited Measurement Dimensions: A single accelerometer typically only captures the response at a single point, making it difficult to fully capture the propagation of stress waves and full-field deformation through the material.

Installation Limitations: Mounting sensors on specimens that are hot, fragile, or in motion is extremely challenging, if not impossible.

Cost and Complexity: While multi-channel data acquisition systems can partially address the issue, they are expensive and complex to integrate.

2. Solution: Non-Contact Laser Vibrometry Impact Testing System

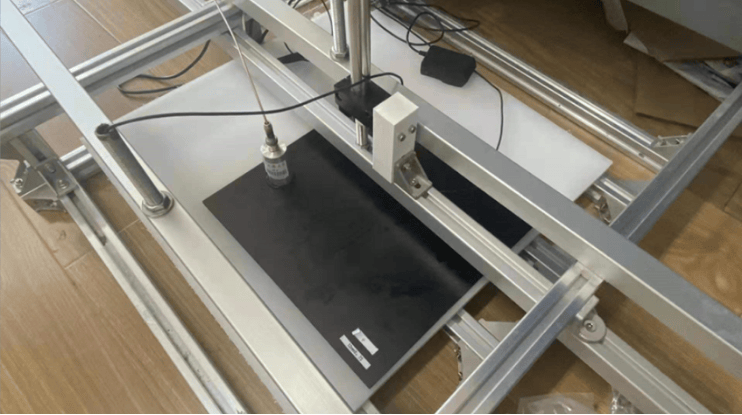

This research utilized the Dynatronic VibroMicro Laser Doppler Vibrometer to build a high-precision, non-contact impact testing platform.

System Configuration:

Core Sensing Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer (featuring high bandwidth and high dynamic range).

Impact Excitation Device: Drop-weight impact tester or Split Hopkinson Pressure Bar (SHPB) to generate controlled, reproducible transient pulse loads.

Synchronization Trigger System: Using the impact event itself (e.g., the signal generated at the moment of hammer contact) as an external trigger to synchronize the start of VibroMicro data acquisition.

Data Acquisition & Processing: High-performance data acquisition system and dedicated analysis software for recording complete transient waveforms and post-processing.

Test Samples:

A. Carbon Fiber Reinforced Polymer (CFRP) Laminate (Assessing its impact damage resistance).

B. 3D-Printed Lattice Metamaterial (Studying its impact energy absorption and dispersion mechanisms).

C. Metal-Ceramic Functionally Graded Material (FGM) (Analyzing stress wave propagation and reflection characteristics at different material interfaces).

3. Test Method & Procedure

Specimen Preparation & Mounting: Secure the material specimen in the support fixture according to requirements. Ensure an unobstructed optical path for the laser vibrometer.

Measurement Planning: Plan the locations of laser measurement points based on the research objectives. For example, arrange multiple points along the centerline of a laminate to track stress wave propagation; for lattice materials, measure the response of nodes and struts separately.

System Calibration & Synchronization: Set the VibroMicro's measurement parameters (e.g., velocity/displacement range, filter frequency) and connect the sync trigger line to ensure capture of the very beginning of the impact event.

Test Execution: Activate the impact device. Upon receiving the trigger signal, the VibroMicro records the vibration velocity/displacement time-history curves for each point at high speed.

Data Reconstruction: The software automatically integrates/differentiates the velocity signal to simultaneously generate instantaneous displacement and instantaneous acceleration curves

4. Results & In-Depth Analysis

4.1 Case 1: Impact Damage Assessment of CFRP Laminates

Traditional Method Limitations: Post-impact ultrasonic C-scan or visual inspection assesses damage area but cannot reveal the dynamic response during the impact event.

Laser Vibrometry Results:

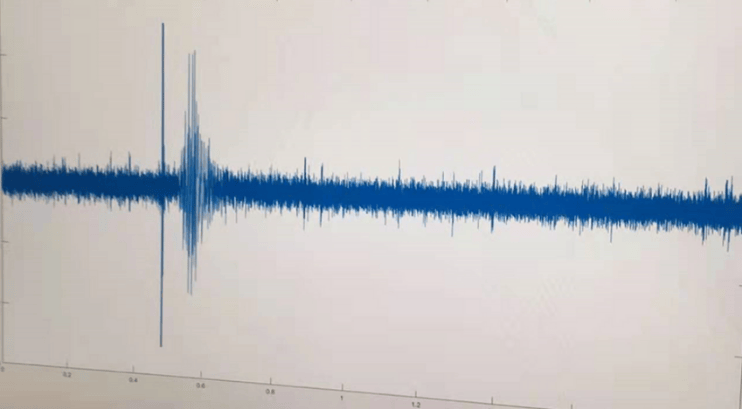

Time-History Curves: Clearly captured the complex velocity signal at the impact point, resulting from the superposition of contact, rebound, and structural vibration.

Wave Propagation Visualization: Successfully reconstructed the spatiotemporal evolution of flexural waves and shear waves propagating through the plate by analyzing signals from multiple points, precisely measuring wave speeds.

Damage Initiation Identification: Observed a sudden high-frequency oscillation spike in the acceleration curve, corresponding to the initiation of matrix micro-cracking, providing an early indicator for damage prediction.

Engineering Value: Provided critical dynamic response data for improving the delamination resistance and toughness of composites, enabling more accurate validation of simulation models.

4.2 Case 2: Energy Absorption Mechanism of 3D-Printed Lattice Metamaterials

Problem: This lattice material exhibited excellent energy absorption rates in quasi-static tests, but its mechanical behavior under dynamic impact was unknown.

Laser Vibrometry Results:

Dynamic Compression Process: The displacement curve accurately recorded the dynamic crushing process of the impact face over millisecond timescales.

Stress Wave Management: The velocity curve revealed wave filtering effects and local resonance energy dissipation phenomena as stress waves propagated through the periodic lattice structure.

Failure Mode: By analyzing the phase differences in responses from different measurement points, clearly distinguished whether the structure underwent global uniform compression or local shear failure.

Engineering Value: Directly validated the design concept of lattice structures as impact energy absorbers and provided a basis for optimizing their unit cell topology for specific impact spectra.

5. Summary of Core Advantages

In this case study, the Dynatronic VibroMicro demonstrated irreplaceable advantages in impact testing:

High Fidelity: Truly non-contact, ensuring authentic capture of the dynamic response of lightweight or small specimens without mass-loading.

Rich Information Dimension: Simultaneously acquires three key parameters—displacement, velocity, and acceleration—providing a comprehensive description of the transient dynamic process.

High Spatiotemporal Resolution: The small laser spot enables precise measurement of responses in micro-areas, coupled with high temporal resolution sufficient to capture high-frequency vibrations induced by impact.

System Flexibility & Efficiency: The compact device integrates easily into existing impact test platforms, features quick setup, and significantly enhances research efficiency.

6. Commercial Application Prospects

Aircraft Manufacturers: For certifying the safety of composite wings, interior panels, etc., under impact loads like bird strike or hail.

Protective Equipment R&D Institutes: For designing and evaluating the dynamic response of high-performance ballistic armor and blast-resistant structures under shock waves.

Electronics Industry: For measuring the transient response of microchips and MEMS devices during drop tests, improving product reliability.

Automotive Safety Labs: As a vital complement to traditional sensors for studying the behavior of lightweight materials and structures during crash events.

Conclusion:

The Dynatronic VibroMicro Laser Doppler Vibrometer successfully elevates transient impact testing from traditional "result observation" (e.g., damage area) to a new level of "process analysis" (dynamic wave propagation, energy evolution). It has become an indispensable precision measurement tool in the field of impact dynamics for both cutting-edge academic materials research and high-tech industrial sectors, powerfully driving the design and development of safer and more durable advanced materials.