Laser Ultrasonic Testing for Material Characterization

1. Application Overview

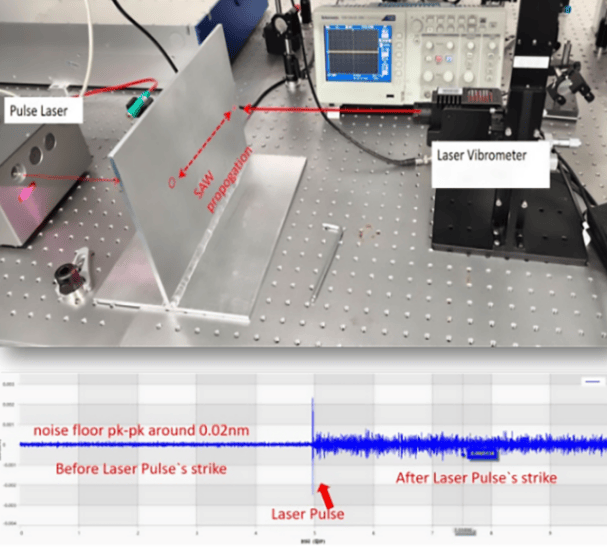

This case presents the implementation of laser ultrasonic testing combined with VibroMicro Laser Doppler Vibrometer for non-destructive material characterization of aluminum alloy plates. The methodology enables precise detection of internal defects and material property assessment through advanced vibration measurement techniques. validation and quality assurance.

2. Technical Principle

Laser ultrasonic testing integrates pulsed laser excitation with laser Doppler vibrometry to create a completely non-contact measurement system:

Excitation Phase: A high-energy pulsed laser generates ultrasonic waves through thermoelastic effect

Detection Phase: VibroMicro laser Doppler vibrometer detects surface vibrations on the opposite side

Synchronization: Precise triggering ensures accurate timing correlation between excitation and detection

3. System Configuration

VibroMicro Laser Doppler Vibrometer with nanometric resolution

High-energy Pulsed Laser System (Nd: YAG, 1064 nm wavelength)

Synchronization Electronics for precise trigger management

XYZ Positioning System for automated scanning

Data Acquisition Unit with high sampling rate (≥100 MS/s)

Advanced Signal Processing Software

4. Measurement Methodology

4.1 Sample Preparation

Aluminum alloy plate (600×600×5 mm)

Surface preparation to ensure optimal laser reflection

Reference markers for coordinate registration

4.2 Data Acquisition Protocol

Grid-based scanning with 2 mm spatial resolution

Multiple averages per measurement point (typically 16)

Environmental vibration isolation

Temperature stabilization at 23±1°C

5. Results and Analysis

5.1 Signal Characteristics

Typical pulse amplitude: 1.2 nm (half-peak value)

Pulse duration: 50 μs

Signal-to-noise ratio: >30 dB

Clear identification of longitudinal and shear wave components

5.2 Material Property Assessment

Wave velocity mapping revealed variations of ±2.5% across the plate

Attenuation coefficients showed correlation with material microstructure

Anisotropy detection in rolling direction

5.3 Defect Detection Capability

Successful identification of artificial defects (0.5-2 mm diameter)

Detection of laser welding imperfections

Mapping of material inhomogeneities

Characterization of thermal stress distribution

6. Technical Advantages Demonstrated

6.1 Measurement Performance

Non-contact operation eliminates couplant-related issues

High spatial resolution (sub-millimeter capability)

Superior sensitivity to weak vibration signals

Absolute calibration traceable to international standards

6.2 Operational Benefits

Rapid scanning capability (up to 100 points/hour)

Suitable for complex geometries and high-temperature applications

Minimal sample preparation requirements

Comprehensive data acquisition and analysis workflow

7. Quality Control Applications

The methodology has been successfully implemented for:

Weld quality assessment in automotive components

Detection of kissing bonds in aerospace structures

Thickness mapping of corrosion-prone areas

Process control in additive manufacturing

Material certification for nuclear industry applications

8. Comparative Analysis

Compared to conventional ultrasonic testing:

3x better resolution for near-surface defects

Elimination of transducer coupling variability

Enhanced capability for automated inspection

Superior performance on rough surfaces

9. Conclusion

The integration of VibroMicro Laser Doppler Vibrometer with laser ultrasonic testing provides a powerful solution for advanced material characterization. The system's high sensitivity, combined with completely non-contact operation, enables reliable detection of minute defects and detailed mapping of material properties. This case demonstrates the methodology's effectiveness for quality control in demanding industrial applications, particularly where conventional ultrasonic methods face limitations. The technical approach offers significant advantages for manufacturers requiring precise, reliable, and efficient non-destructive testing capabilities.