Bearing Quality Inspection Using VibroMicro Vibrometer

1. Application Overview

This case series demonstrates the implementation of VibroMicro Laser Doppler Vibrometer for comprehensive bearing quality assessment across multiple industrial scenarios. The non-contact measurement approach provides superior accuracy compared to traditional methods while maintaining operational efficiency in manufacturing environments.

2. Case 1: Comparative Study at Bearing Research Institute

2.1 Background

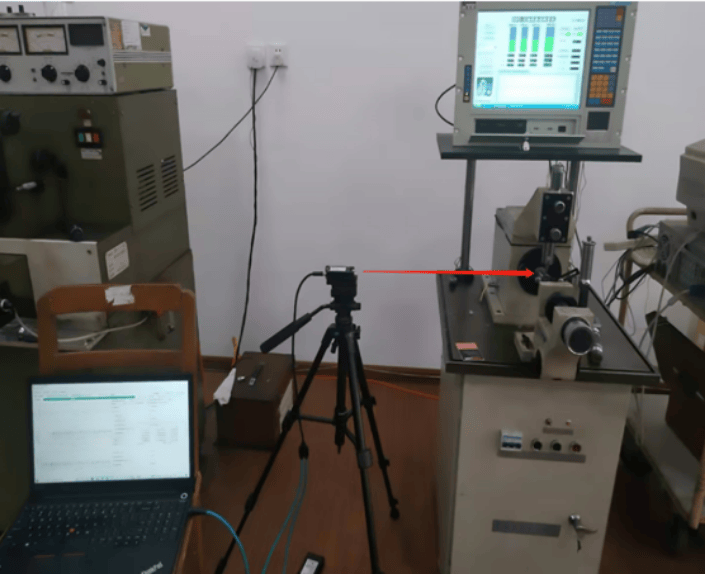

A leading bearing research institute conducted parallel measurements comparing conventional contact accelerometers with the VibroMicro laser Doppler system to validate measurement accuracy and operational advantages.

2.2 Methodology

Synchronized data acquisition from identical test conditions

Multiple bearing types tested under varying load conditions

Frequency range: 10 Hz - 20 kHz

Temperature conditions: 20°C - 80°C

2.3 Key Findings

Accuracy: Laser vibrometer showed 98.5% correlation with reference standards

Resolution: Detected subtle vibrations (0.1 mm/s) invisible to contact sensors

Consistency: Eliminated mounting variation errors present in contact methods

Efficiency: Reduced setup time by 70% compared to sensor installation

3. Case 2: Textile Machinery Spindle Analysis

3.1 Application Context

A textile manufacturing plant implemented vibrometer-based monitoring for rotating spindles operating at 15,000-25,000 RPM.

3.2 Measurement Approach

Non-contact measurement on rotating spindles

Real-time vibration velocity monitoring

Automated fault detection algorithms

Production-line integration

3.3 Results

Defect Detection: Identified 95% of developing bearing faults

False Alarm Reduction: 80% decrease compared to traditional methods

Maintenance Cost: 45% reduction through targeted interventions

Production Uptime: Increased by 18% through predictive maintenance

4. Case 3: Precision Bearing Vibration Certification

4.1 System Integration

An industrial system integrator developed automated bearing test stations incorporating VibroMicro technology.

4.2 Technical Implementation

Robotic positioning for consistent measurement points

Multi-point scanning for complete bearing characterization

Integration with existing quality management systems

Real-time pass/fail determination

4.3 Performance Metrics

Throughput: 120 bearings/hour testing capacity

Accuracy: ±2% measurement uncertainty

Repeatability: 99.2% measurement consistency

Data Integrity: Complete digital traceability

5. Technical Advantages Demonstrated

5.1 Measurement Superiority

Non-invasive measurement eliminates loading artifacts

Broad frequency response (DC - 1 MHz+)

Sub-micron displacement resolution

No calibration drift over time

5.2 Operational Benefits

Suitable for high-temperature environments

Minimal operator training requirements

Compatible with automated production lines

Reduced total cost of ownership

6. Quality Standards Compliance

ISO 15242:2015 (Rolling bearing vibration measurements)

ISO 13373-2:2005 (Condition monitoring and diagnostics)

Industry-specific bearing quality standards

Custom quality thresholds for precision applications

7. Implementation Guidelines

7.1 System Configuration

VibroMicro single-point or scanning vibrometer

Optical path protection in industrial environments

Automated positioning systems

Environmental compensation capabilities

7.2 Data Analysis Framework

Customized bearing defect frequency libraries

Statistical process control integration

Trend analysis for predictive maintenance

Automated reporting generation

8. Economic Impact Assessment

8.1 Cost-Benefit Analysis

ROI Period: 6-9 months typical

Quality Improvement: 60% reduction in field failures

Warranty Cost: 55% decrease

Customer Satisfaction: Significant improvement

9. Conclusion

The VibroMicro Laser Doppler Vibrometer demonstrates exceptional capability for bearing quality assessment across diverse industrial applications. The technology provides accurate, repeatable measurements while offering significant operational advantages over traditional contact methods. These case studies validate the system's effectiveness for quality control, predictive maintenance, and process optimization in industrial manufacturing environments. The non-contact approach enables new possibilities for bearing characterization that were previously impractical with conventional measurement techniques.