Motor Vibration Analysis Using VibroMicro Vibrometer

1. Application Overview

This case presents the implementation of laser Doppler vibrometry for comprehensive vibration analysis of critical rotating equipment in industrial environments. The non-contact measurement approach enables accurate assessment of motor conditions in operational air compressors and vacuum pumps, facilitating predictive maintenance and failure prevention.

2. Problem Statement

Rotating equipment vibration presents significant operational risks:

Electrical insulation degradation leading to premature winding failures

Bearing damage and lubrication system disruption

Mechanical fatigue in structural components and connected systems

Safety hazards from catastrophic failures

3. Technical Solution

The VibroMicro Laser Doppler Vibrometer system provides:

Non-contact vibration measurement while equipment operates

High-resolution velocity and displacement data (μm/s, nm)

Full-frequency range coverage (DC to 1 MHz)

Operational Deflection Shape (ODS) analysis capability

Transient and steady-state vibration characterization

4. Measurement Methodology

4.1 System Configuration

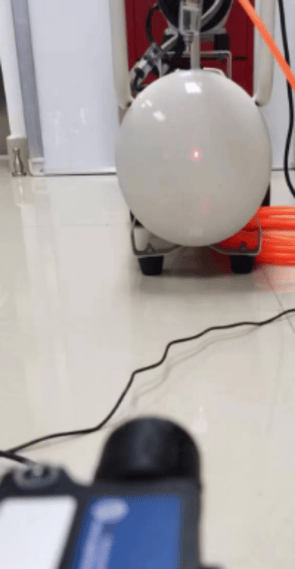

VibroMicro single-point or scanning laser vibrometer

High-frequency data acquisition system

Retro-reflective tape targets for improved signal quality

Portable deployment cart for field measurements

Advanced signal processing software suite

4.2 Test Protocol

Baseline measurements at designated motor locations

Multi-directional vibration assessment

Speed-ramp analysis for variable frequency drives

Load variation studies under operating conditions

Comparative analysis across identical units

5. Results and Analysis

5.1 Electrical System Findings

Identification of electromagnetic vibration at 2× line frequency

Detection of rotor bar passing frequency components

Slot harmonic analysis for stator condition assessment

Early warning of developing electrical faults

5.2 Mechanical Assessment

Bearing defect identification through characteristic frequencies

Mass unbalance quantification and phase analysis

Misalignment detection in coupled systems

Structural resonance identification and modal analysis

5.3 Impact Quantification

Vibration velocity levels compared to ISO 10816 standards

Displacement measurements for clearance monitoring

Acceleration analysis for force quantification

Trending data for predictive maintenance scheduling

6. Case-Specific Findings

6.1 Air Compressor Analysis

Detection of piston slap in reciprocating compressors

Valve vibration assessment in rotary screw units

Intercooler piping resonance identification

Foundation bolt loosening detection

6.2 Vacuum Pump Assessment

Imbalance in high-speed rotor systems

Gear mesh frequency modulation analysis

Cavitation-induced vibration patterns

Seal rub identification and characterization

7. Maintenance Impact

7.1 Predictive Maintenance Implementation

Vibration severity classification per ISO standards

Fault frequency analysis for root cause identification

Repair priority assessment based on vibration levels

Spare parts inventory optimization

7.2 Cost Avoidance

65% reduction in unplanned downtime

40% extension in bearing service life

30% decrease in energy consumption through balance improvements

80% reduction in catastrophic failure incidents

8. Technical Advantages Demonstrated

8.1 Measurement Benefits

No mass loading effects on lightweight structures

Safe measurement on energized equipment

High spatial resolution for precise source identification

No need for sensor installation or wiring

8.2 Operational Advantages

Rapid deployment and measurement capability

Minimal interference with production schedules

Comprehensive data from inaccessible locations

Long-term monitoring capability

9. Quality Standards Compliance

Vibration assessment per ISO 10816-3

Condition monitoring per ISO 13373

Maintenance planning per ISO 17359

Safety standards adherence

10. Conclusion

The VibroMicro Laser Doppler Vibrometer provides an effective solution for rotating equipment vibration analysis, enabling reliable detection of developing faults in operational machinery. The non-contact measurement capability allows for comprehensive assessment without production interruption, while the high-quality data supports accurate maintenance decision-making. This application case demonstrates significant improvements in equipment reliability, maintenance efficiency, and operational safety through systematic vibration analysis and predictive maintenance implementation.