Ultrasonic Transducer Characterization Using VibroMicro

1. Executive Summary

Characterizing the true transient response of ultrasonic transducers is critical for optimizing their performance in applications such as medical imaging, non-destructive testing, and precision cleaning. This case study demonstrates the use of the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer to capture the high-frequency, transient vibration behavior of a 100 kHz pulsed ultrasonic transducer. The system successfully provided real-time, nanoscale displacement data, revealing the transducer's instantaneous vibration characteristics.

2. Challenge

Pulsed ultrasonic transducers operate by emitting short, high-frequency energy bursts. Their performance is determined by the precise shape of the emitted waveform, including ring-up and ring-down dynamics. Traditional measurement methods often lack the bandwidth or non-contact capability to accurately capture these rapid, microscopic displacements without influencing the transducer's natural behavior.

3. Solution: High-Bandwidth, Non-Contact Displacement Measurement

The Dynatronic VibroMicro VM-S-100 was selected for its ability to directly and accurately measure transient vibrations without contact. Its key advantages for this application include:

Non-Contact Operation: Eliminates mass-loading, ensuring the measured response is that of the transducer itself, not the transducer-sensor system.

High Bandwidth: Easily covers the 100 kHz fundamental frequency and higher harmonics for detailed waveform analysis.

Nanometer Resolution: Provides exceptional displacement resolution, capable of resolving the minute vibrations characteristic of ultrasonic transducers.

Real-Time Waveform Capture: Directly outputs the instantaneous displacement versus time, capturing the complete transient response.

4. Test Setup

Device Under Test (DUT): 100 kHz Pulsed Ultrasonic Transducer

Core Measurement Equipment: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Procedure:

The ultrasonic transducer was driven by a pulsed signal from its generator.

The laser beam from the VM-S-100 was focused directly on the center of the transducer's radiating surface.

The vibrometer's analog or digital output was recorded synchronously with the trigger pulse.

5. Data Analysis & Results

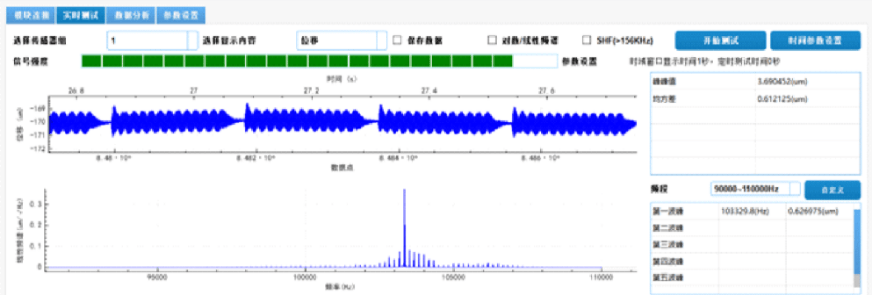

The VM-S-100 directly measures the out-of-plane velocity and displacement of the transducer surface as a function of time.

Key Result:

The VibroMicro system successfully recorded the transducer's displacement information in real-time, obtaining an instantaneous vibration profile of the sample.

The acquired time-domain data typically reveals:

Ring-Up Time: The time taken for the oscillation to build up to its steady-state amplitude after the pulse is initiated.

Steady-State Operation: The stable, resonant vibration during the pulse.

Ring-Down Time: The decay of the oscillation after the pulse ends, which defines the temporal resolution of the transducer.

Waveform Fidelity: The purity of the sinusoidal vibration and the presence of any non-linearities or distortions.

This instantaneous displacement map is crucial for evaluating the transducer's acoustic output and temporal resolution.

6. Conclusion

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer proved to be an indispensable tool for the dynamic analysis of pulsed ultrasonic transducers. It provided a clear, quantitative, and high-fidelity measurement of the transducer's transient vibration behavior. The ability to obtain a real-time, instantaneous vibration profile with nanometer resolution empowers engineers to validate designs, optimize driving electronics, troubleshoot performance issues, and ensure final product quality with unprecedented accuracy.