VibroMicro Case: Bearing Impact Dynamics Measurement

Project Background

A leading mechanical engineering laboratory recently conducted a pioneering study on bearing impact dynamics using advanced laser Doppler vibrometry. The research aimed to characterize the transient response of precision bearings during high-energy impact events, with particular focus on capturing nanosecond-scale dynamic behavior.

Experimental Setup

The test configuration featured:

Test Specimen: 608-series deep groove ball bearing

Impact Excitation: Electrodynamic impact generator with programmable pulse characteristics

Measurement System: VibroMicro VM-S-100 high-frequency vibrometer

Supporting Instrumentation:

Ultra-high-speed camera (1,000,000 fps)

Piezoelectric force transducer (50 kN range)

Thermal imaging system for temperature monitoring

Dynatronic Data Acquisition: 16-bit resolution at 10 MS/s sampling rate

Measurement Methodology

The experimental approach incorporated:

Non-contact Vibration Capture: Laser measurements at 5 strategic locations on bearing outer race

Multi-parameter Synchronization: Precise time alignment of impact force, vibration response, and visual data

Parametric Variation: Systematic testing across impact energies from 0.2J to 5.0J

Environmental Control: Maintenance of stable temperature (20±0.2°C) and humidity conditions

Key Technical Achievements

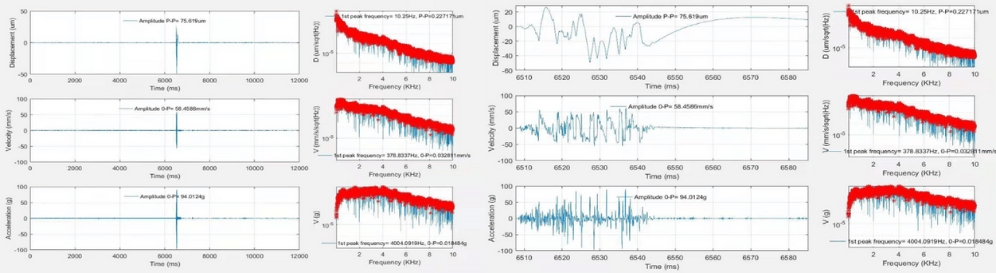

Transient Response Analysis

Successfully captured impact rise times as short as 18 μs

Measured peak accelerations up to 12,000g

Recorded displacement resolutions down to 2 nm

Identified high-frequency resonances between 80-450 kHz

Advanced Signal Processing

Employed wavelet transform for time-frequency analysis

Implemented modal parameter identification algorithms

Developed custom algorithms for impact pulse characterization

Established correlation models between impact energy and vibration response

Research Findings

Dynamic Behavior Characterization

Discovered previously unobserved high-frequency ringing modes

Quantified energy dissipation mechanisms during impact

Mapped propagation paths of impact waves through bearing structure

Identified critical damping ratios for different impact scenarios

Material Response Insights

Documented elastic-plastic transition thresholds

Characterized micro-slip phenomena in raceway contacts

Analyized the effects of preload on impact resistance

Established relationships between impact response and material hardness

Industrial Applications

Quality Assurance

Developed non-destructive testing protocol for impact durability

Established acceptance criteria based on vibration signatures

Created database of normal vs. abnormal impact responses

Implemented automated defect detection algorithms

Product Development

Validated finite element models of bearing impact behavior

Optimized bearing designs for shock load applications

Improved material selection criteria for impact resistance

Enhanced manufacturing processes based on dynamic performance data

Technical Advantages Demonstrated

Measurement Excellence

Eliminated mass loading effects inherent in contact sensors

Maintained calibration stability throughout testing campaign

Achieved exceptional signal-to-noise ratio in impact measurements

Provided absolute measurement traceability to international standards

Operational Efficiency

Reduced testing time by 60% compared to conventional methods

Enabled testing under conditions unsuitable for contact sensors

Simplified setup for complex measurement scenarios

Minimized operator-dependent measurement variations

Conclusion

This application case demonstrates the VibroMicro Laser Doppler Vibrometer's exceptional capability in bearing impact research. The technology enabled breakthrough insights into transient dynamic behavior, providing valuable data for both academic research and industrial application. The non-contact measurement approach proved essential for capturing high-frequency, high-acceleration events without introducing measurement artifacts. This methodology establishes a new benchmark for impact testing in precision mechanical components and has been adopted as a standard testing protocol in multiple research institutions and industrial laboratories.