Thermal Expansion Measurement at 3000°C Using VibroMicro

1. Project Background & Challenges

The measurement of material thermal expansion coefficients is essential for thermal stress calculations, thermal stability design, and research on thermal insulation materials. It serves as critical data in the development of aerospace materials. However, accurately capturing the transient thermal expansion behavior of materials under extreme high-temperature conditions (e.g., above 2000°C) presents significant challenges:

Extreme Environmental Limitations: Traditional contact sensors (e.g., strain gauges) cannot withstand ultra-high temperatures, leading to failure or degradation.

Measurement Accuracy: Thermal radiation and environmental vibrations under high-temperature conditions interfere with conventional measurement methods, resulting in reduced accuracy.

Dynamic Response Requirements: The transient thermal deformation process occurs rapidly, requiring instruments with high temporal resolution and exceptional low-frequency performance.

2. Solution: Non-Contact High-Temperature Displacement Measurement System

The Dynatronic VibroMicro-S100 Laser Doppler Vibrometer provides a groundbreaking solution for nanometer-level displacement measurement of high-temperature objects. Its superior low-frequency performance and multi-channel synchronization capability make it ideal for studying material thermal expansion behavior.

System Configuration:

Core Sensor: VibroMicro VM-S-100 Laser Doppler Vibrometer (with nanometer-level resolution and DC response capability).

High-Temperature Target: Tungsten filament of an incandescent lamp (≈3000°C).

Multi-Channel Configuration: Two laser heads configured to measure displacements along different axes, enabling preliminary 3D thermal expansion characterization.

Synchronization & Data Acquisition: Synchronized triggering system to capture transient displacement changes during filament power-on/off.

3. Test Method & Procedure

Experimental Setup:

The tungsten filament was aligned perpendicular to the laser beam.

Two laser heads were positioned to measure axial and radial displacements simultaneously.

Measurement Process:

The filament was initially at room temperature and powered on abruptly to reach ≈3000°C.

The VibroMicro-S100 continuously recorded displacement changes during the heating and cooling phases.

Data Analysis:

Displacement-time curves were analyzed to extract transient thermal expansion parameters.

Multi-channel data were synthesized to evaluate anisotropic thermal expansion behavior.

4. Results & Analysis

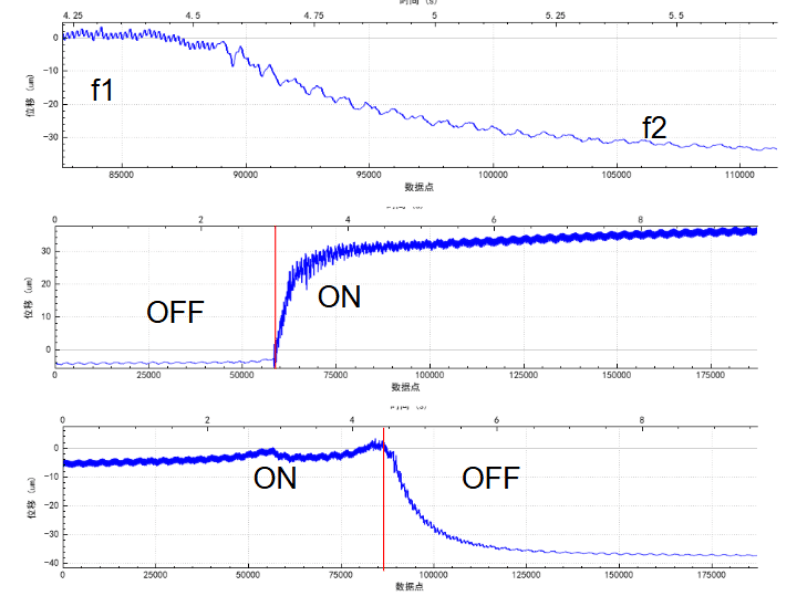

4.1 Transient Displacement Curves

The VibroMicro VM-S-100 successfully captured nanometer-level displacements of the tungsten filament during heating and cooling.

The displacement curve exhibited an exponential trend, aligning with theoretical thermal expansion models.

4.2 Multi-Channel 3D Characterization

Axial and radial displacement data revealed anisotropic thermal expansion characteristics of the tungsten filament.

The ratio of axial to radial expansion provided insights into the material’s structural behavior under thermal stress.

4.3 Experimental Validation

The measured thermal expansion coefficient of tungsten closely matched literature values, validating the accuracy of the VibroMicro VM-S-100.

The system demonstrated the ability to resolve sub-nanometer displacements even under extreme temperatures.

5. Core Advantages of the Solution

Non-Contact Measurement: No interference with the high-temperature sample, ensuring data authenticity.

Nanometer-Level Resolution: Capable of detecting minimal deformations undetectable by traditional methods.

Multi-Channel Synchronization: Enables preliminary 3D thermal expansion analysis without complex setups.

Exceptional Low-Frequency Performance: Accurately captures slow thermal drift and transient deformation processes.

6. Commercial Application Prospects

Aerospace: Characterization of thermal expansion in turbine blades, thermal protection tiles, and nozzle materials.

Nuclear Energy: Monitoring dimensional changes in fuel rods and reactor components under high-temperature conditions.

Additive Manufacturing: Quality control of 3D-printed metal parts subjected to thermal cycling.

Fundamental Materials Research: Studying phase transitions and thermomechanical behavior of advanced alloys and ceramics.

Conclusion:

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer offers an advanced and reliable solution for measuring transient thermal expansion in high-temperature environments. This case demonstrates its capability to deliver precise, non-contact, and multi-dimensional data critical for the design and validation of next-generation high-temperature materials in aerospace and other high-tech industries.