Solder Joint Virtual Welding Detection with VibroMicro

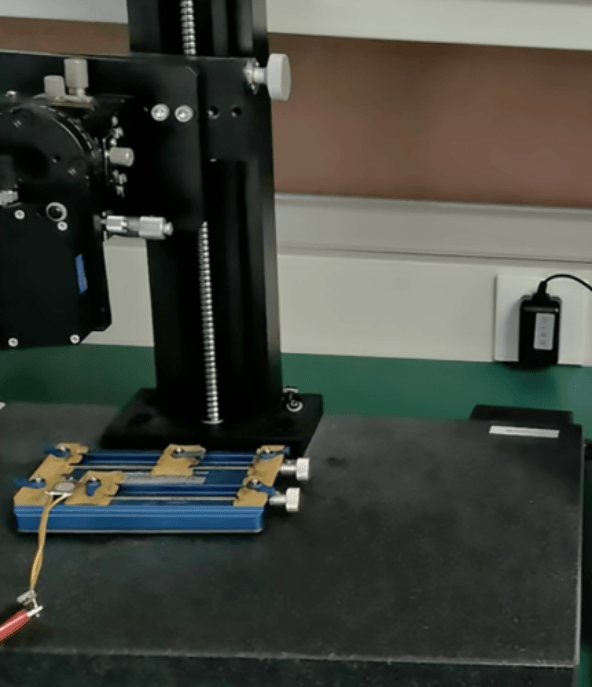

1. System Overview

This solution utilizes the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer to achieve non-contact, high-precision detection of virtual soldering (incomplete solder connections) in electronic components. By analyzing the vibration characteristics of solder joints under excitation, the system identifies abnormalities in structural stiffness and connection quality, enabling efficient and accurate defect screening.

2. System Components

2.1 Excitation System

Composition:

Signal generator

Power amplifier

Electrodynamic shaker or piezoelectric actuator

Stinger rod (for force transmission)

Force sensor (optional, for input force monitoring)

Excitation Methods:

Mechanical Shaker: Suitable for broad-frequency range sweeps on PCBs or components.

Impact Hammer: Portable for localized excitation of specific solder joints.

Ultrasonic Transducer: High-frequency excitation for micro-scale joint inspection.

Laser Ultrasound: Non-contact excitation for delicate or miniaturized components.

2.2 VibroMicro VM-S-100 Laser Doppler Vibrometer

Key Features:

Non-contact measurement with nanometer-level displacement resolution.

Wide frequency bandwidth (DC to 25MHz range) for capturing high-frequency resonances.

Compatible with automated scanning for batch inspection.

2.3 Spectral Analysis Software

Functions:

Real-time vibration data acquisition and frequency response function (FRF) calculation.

Resonance peak identification and modal parameter extraction.

Automated threshold-based defect classification.

3. Working Principle

Excitation:

The excitation system applies a controlled swept-sine or broadband signal to the test specimen (e.g., PCB), inducing vibrations in solder joints.

Measurement:

The VibroMicro VM-S-100 measures the vibration velocity/displacement of the solder joint surface without physical contact.

Analysis:

Healthy Solder Joint: Exhibits high stiffness, resulting in higher resonant frequencies and a distinct FRF.

Virtual Solder Joint: Reduced stiffness due to incomplete bonding, leading to lower resonant frequencies, distorted FRF, or abnormal damping.

Defect Identification:

Predefined thresholds for resonance frequency shifts or FRF deviations are used to flag defective joints automatically.

4. Implementation Workflow

Setup:

Mount the test specimen on a vibration-isolation platform.

Align the laser beam perpendicular to the solder joint surface.

Position the excitation source (e.g., shaker stinger) at a designated input point.

Calibration:

Adjust the excitation signal amplitude to avoid overloading or damaging components.

Validate measurement accuracy using a reference solder joint.

Testing:

Execute a frequency sweep (e.g., 100 Hz–10 kHz) while recording vibration data.

Repeat for multiple joints in automated mode using a motorized stage.

Post-Processing:

Compare FRFs of test joints against a golden reference.

Flag joints with resonant frequency deviations >5% or abnormal damping ratios.

5. Advantages of the Solution

Non-Contact: Avoids mass-loading effects and physical damage to delicate components.

High Sensitivity: Detects nanoscale vibrations indicative of micro-cracks or voids.

Speed and Automation: Compatible with robotic stages for high-throughput PCB inspection.

Versatility: Adaptable to through-hole, SMD, and BGA solder joints.

6. Applications

Automotive Electronics: ECU PCB solder joint quality assurance.

Aerospace: Avionics component reliability testing.

Consumer Electronics: Smartphone and wearable device manufacturing.

Medical Devices: Critical PCB inspections for implantable devices.

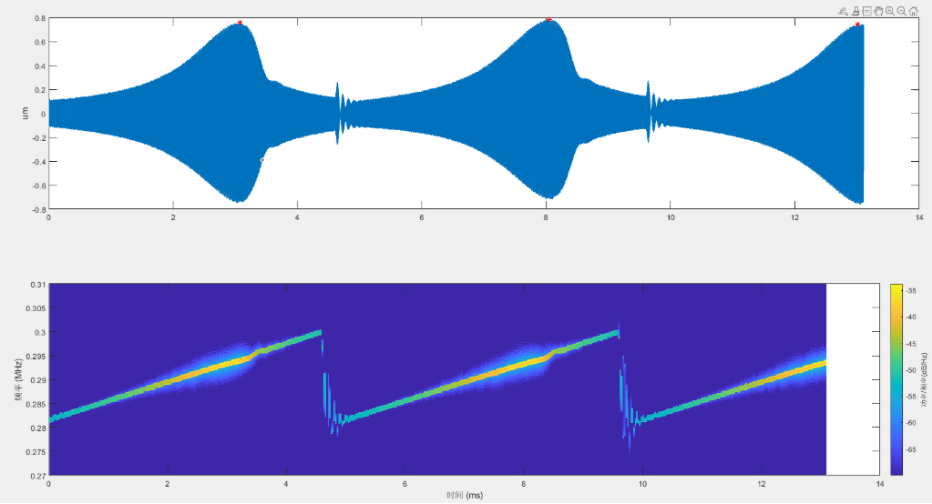

7. Example Results

Healthy Joint: Resonant frequency at ~2.5 kHz with a sharp FRF peak.

Virtual Joint: Resonant frequency shifted to ~1.8 kHz with a broadened, lower-amplitude peak.

Conclusion:

The Dynatronic VibroMicro VM-S-100-based solution provides a robust, non-destructive method for detecting solder joint defects. By leveraging vibration signature analysis, it enhances quality control processes in industries where solder reliability is critical, reducing field failures and improving product lifespan.