Ultrasonic Tool Tip Vibration Measurement

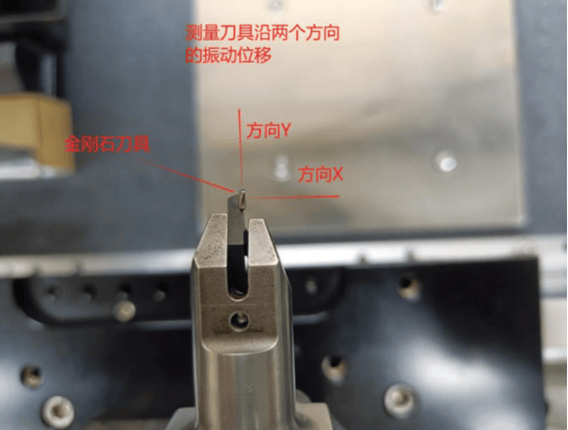

Application: Vibration verification measurement for ultrasonic-assisted machining tool tips, with a specific focus on accurately measuring the independent lateral and longitudinal displacement components during operation.

Extended Technical Description:

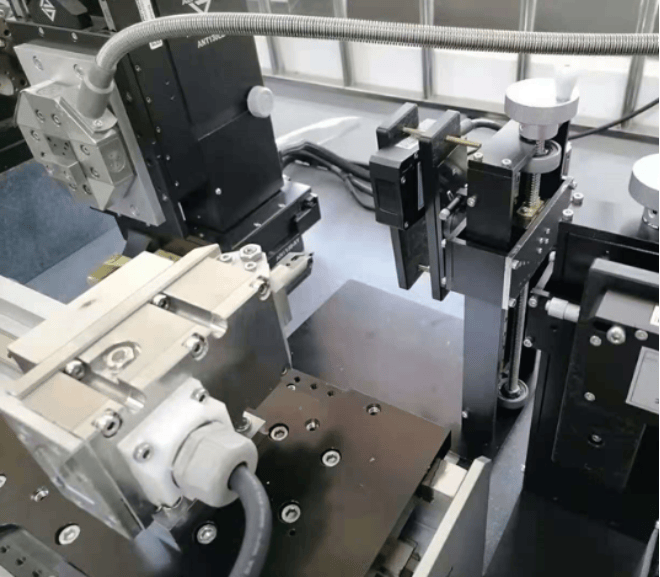

This advanced solution utilizes VibroMicro Laser Doppler Vibrometers to perform highly precise, non-contact vibration measurements on ultrasonic tool tips while they are in operation. The system is specially engineered to effectively decouple and accurately quantify both the primary longitudinal displacement, which occurs along the axis of the tool, and the parasitic lateral displacement, which occurs perpendicular to the tool axis. These measurements achieve micron-level resolution, ensuring exceptional accuracy and reliability in monitoring tool vibrations.

Key Measurement Capabilities:

1. Longitudinal Vibration Analysis

Measures axial vibration amplitude at the tool tip

Characterizes resonant frequency and harmonic response

Verifies optimal energy transmission along the tool structure

2. Lateral Vibration Assessment

Quantifies unwanted transverse vibrations

Identifies potential bending modes and node locations

Evaluates tool stability during operational conditions

Technical Advantages:

Non-contact measurement eliminates mass loading effects on delicate tool structures

High-frequency response (up to 1 MHz) captures full ultrasonic spectrum

Sub-micron displacement resolution ensures accurate amplitude verification

Automated scanning capability for full 3D vibration characterization

Quality Control Applications:

Tool tip performance validation

Manufacturing consistency checks

Resonance frequency verification

Operational amplitude confirmation

Batch quality certification

This measurement approach provides essential and detailed data that is crucial for optimizing the design of ultrasonic tools, verifying the quality of manufacturing processes, and ensuring consistent and reliable performance in a wide range of precision machining applications.