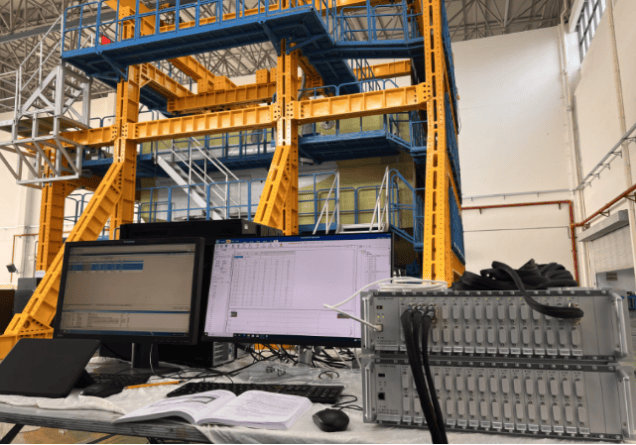

Wind Tunnel Test Solution for High-Speed Data Acquisition

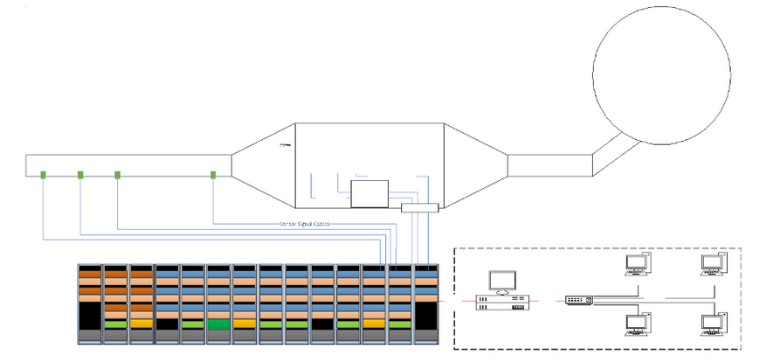

Dynatronic’s wind tunnel test solution enables high-speed, high-precision synchronous acquisition of pressure, heat flux, and other sensor signals. With modular DAQ systems, per-channel processing, and low-latency synchronization, the system ensures accurate, real-time measurement and anti-interference performance for aerodynamic, heat transfer, and aeroelasticity experiments.

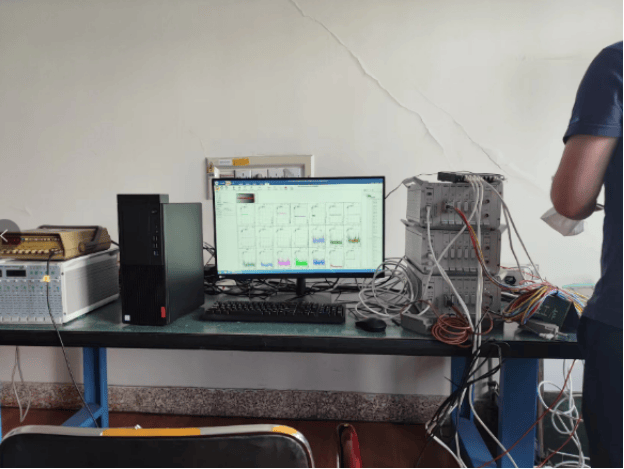

1500-Channel Integrated Data Acquisition System

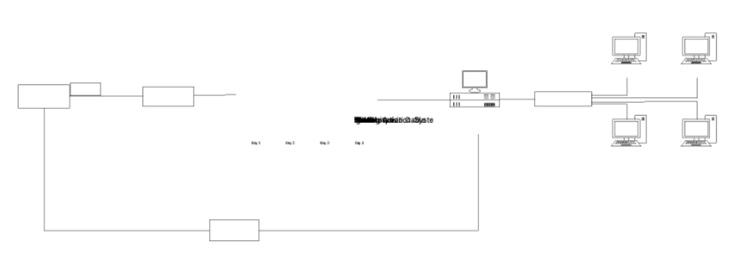

Dynatronic’s 1500-channel DAQ system delivers high-precision strain, displacement, and structural measurements for large-scale experiments. Featuring a hybrid centralized/distributed architecture, FPGA-triggered dynamic sampling, and multi-client support, the system ensures sub-μs synchronization, anti-interference performance, and continuous high-speed data capture, making it ideal for wind tunnel tests and full-aircraft structural evaluations.

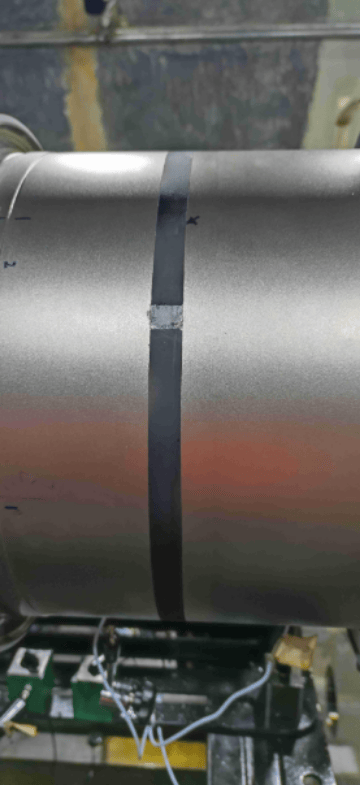

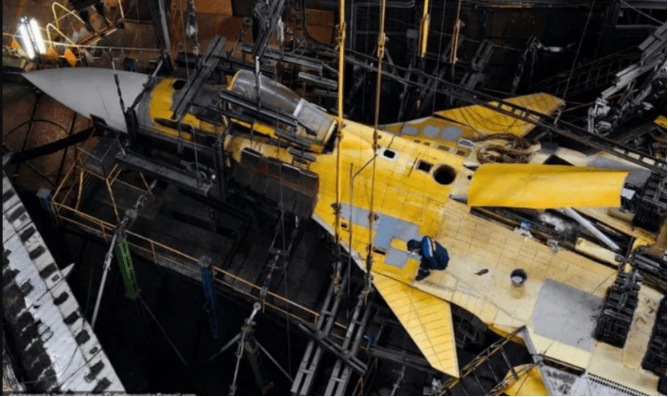

Aero-Engine Blade-Out Test & Containment Evaluation

Full-scale turbofan blade-out testing evaluated containment systems, rotor dynamics, and fire safety. Using DE-Series DAQ systems with μs-level synchronization, engineers captured sub-millisecond events, validated FEM predictions, and verified compliance with FAR and EASA engine safety standards, supporting CAAC and FAA approvals while enhancing predictive rotor failure models.

Aircraft Landing Gear Static Load & Deformation Test

Full-scale static load testing of aircraft landing gear quantified stress distribution, validated FEA models, and revealed nonlinear effects under overload conditions. Using 16 SE-86H systems, engineers identified critical stress hotspots, improved design margins, and established in-service strain limits, supporting FAR compliance and next-generation landing gear optimization.

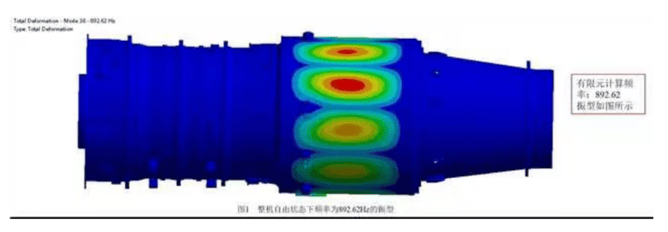

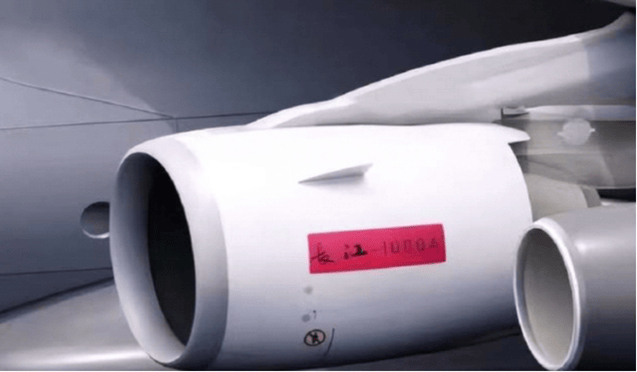

Aero-Engine High-Pressure Rotor Vibration & Stability Test

Dynamic testing of the CJ-XX engine’s high-pressure rotor evaluated vibration, blade dynamics, and rotor stability. Using DE-924U DAQ systems and phase-locked acquisition, engineers validated FEM predictions, verified tip clearance, and confirmed damping effectiveness, providing critical data for FAA compliance, manufacturing adjustments, and improved engine performance.

Aero-Engine Casing Modal Analysis & Vibration Assessment

Experimental modal analysis on a turbofan engine casing was conducted to validate FEM models, identify resonance risks, and confirm structural margins. Using DE-928U DAQ systems and laser vibrometry, key vibration modes were measured, enabling design validation, damping optimization, and compliance with ISO and ASME testing standards.

SUAV Operational Vibration Testing & Airframe Analysis

A comprehensive vibration survey was conducted on a MALE-class UAV using 4 rugged RE-846U DAQ systems. Structural dynamics, propulsion-induced vibrations, and control system interactions were measured across 20 flight regimes, providing data for design optimizations, predictive maintenance, and UAV certification compliance.

Strain Testing Report for Next-Generation Rocket Thruster

A detailed report on dynamic strain testing for a next-generation liquid rocket engine thruster, ensuring structural integrity and enabling advanced design optimization.

Supersonic Model Aircraft Vibration & Strain Testing

Discover how the Chinese Academy of Sciences tested a Mach 1.0 supersonic model for vibration and strain under extreme acceleration, temperature, and aerodynamic loads.

Engine Speed and Oil Pressure Testing Explained

A detailed look at how engine speed and oil pressure tests help validate aircraft engine performance, lubrication efficiency, and rotational dynamics.

Wind Tunnel Structural Strain Testing for Enhanced Integrity

A university research team used the SE-86H High-Speed Static Stress-Strain Testing System to monitor wind tunnel integrity, uncover hidden stresses, and implement structural upgrades for safer, more efficient aerodynamic testing.

Helicopter Rotor Telemetry Test with Wireless Systems

Discover how advanced wireless systems enabled real-time performance testing of helicopter main and tail rotors, capturing dynamic strain, vibration, and torque under operational conditions.

Static Load Testing for Aircraft Fuselage & Wings

A detailed case study of static load testing on an aircraft fuselage and wing, using Dynatronic SE-864U systems for stress-strain analysis and FEM correlation.

Fatigue Loading Test on Aircraft Pressure Cabin

In March 2023, a research institution tested a pressurized aircraft cabin using 12 SE-Series systems with 128 channels. The test simulated 50,000 cycles, integrated MTS control, and applied automated fatigue analysis to validate FEM predictions and identify structural reinforcements for compliance.

Spacecraft Recovery Tower Modal Testing with WW-826D

In February 2023, the Aeronautical Engineering Research Institute conducted modal testing on a 217m spacecraft recovery tower using Dynatronic’s WW-826D wireless systems. The tests identified key bending and torsional modes, validated FEM predictions, and demonstrated the system’s capability for large-scale structural analysis in harsh outdoor conditions.

Flight Test of Domestic Aircraft-Borne Engine

CJ-1000A engine flight test on Y-20 captured by RE-Series DAQ, tracking vibration, blade strain, and key parameters for China’s domestic aviation milestone.

UAV Structural Strain Testing with SE-98 System

Comprehensive UAV strain testing using the SE-98 system for real-time strain data acquisition, model validation, and structural strength assurance.

Advanced Flight Parameter Monitoring for Fighter Aircraft

Military-grade flight parameter monitoring system for next-gen fighter aircraft, offering vibration, noise, temperature, and pressure acquisition with advanced data management.

Engine Parameter Recorder for Advanced Flight Monitoring

An advanced portable solution for real-time engine monitoring, trend analysis, and PHM of critical components during flight tests.

Rotating Force and Torque Measurement for Aerospace Testing

NUAA uses the RU-846 Rugged Data Recorder for precise force and torque measurements in rotating structures, ensuring accuracy in aerospace applications.