UAV Structural Strain Testing with SE-98 System

Project name: UAV Structural Strain Testing with SE-98 System

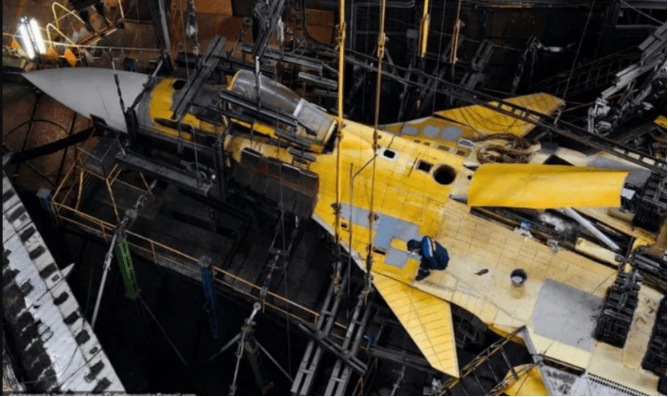

In January 2023, an aircraft manufacturing facility in Guizhou conducted a full-scale structural strength evaluation on a next-generation UAV model. The goal was to verify the durability of critical components under operational and extreme load conditions before certification and mass production.

Testing Methodology

To capture accurate strain data, engineers installed high-precision strain gauges across key structural points, including wing root joints, fuselage frames, and landing gear attachment areas. The UAV underwent simulated operational stresses through a controlled structural loading process, replicating real-world flight conditions and emergency scenarios.

The testing was powered by the Dynatronic SE-98 Dynamic Stress-Strain Testing and Analysis System, which enabled:

Real-time strain data acquisition at a sampling rate of 10kHz

Synchronized multi-channel measurement across 32 inputs

Dynamic deformation visualization for accurate structural assessment

Key Outcomes

Verified structural integrity under designed load cases

Correlated experimental strain measurements with finite element analysis (FEA) models

Established baseline strength characteristics for future UAV development programs

Technical Specifications

Measurement range: ±5000με

Accuracy: 0.5% FS

Temperature compensation: -20°C to +80°C

Compatible with foil/resistive strain gauges

Conclusion

The UAV structural strain testing provided a comprehensive assessment of the aircraft’s critical components under both operational and extreme load conditions. By leveraging the high-precision, real-time capabilities of the SE-98 Dynamic Stress-Strain Testing and Analysis System, engineers were able to capture synchronized multi-channel strain data and visualize dynamic deformations with exceptional accuracy. The results not only confirmed the structural integrity of the wing roots, fuselage frames, and landing gear attachment points but also validated the correlation between experimental measurements and finite element analysis (FEA) models. These insights established a robust baseline for future UAV designs, supporting ongoing development, optimization, and certification processes. Furthermore, the project demonstrated the value of integrating advanced stress-strain testing into standard qualification procedures, ensuring enhanced safety, reliability, and performance in next-generation UAV platforms.

This rigorous testing protocol is now integrated into the manufacturer’s standard qualification process, ensuring improved safety and performance in UAV designs. By leveraging Dynatronic’s SE-98 system, the project achieved precise, repeatable results that meet aviation standards for structural validation.