Fatigue Loading Test on Aircraft Pressure Cabin

Project name: Fatigue Loading Test on Aircraft Pressure Cabin

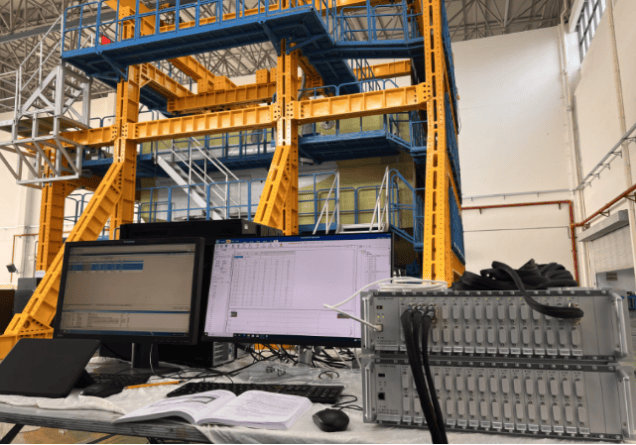

March 2023 – A research institution conducted fatigue strength testing on a pressurized aircraft cabin using 12 × 128-channel SE-Series Dynamic Stress-Strain Testing and Analysis Systems.

Test Setup & Methodology

Sensor Deployment

Strain gauges & sensors installed at key structural points to monitor fatigue behavior.

Multi-axis stress measurement for critical joints, frames, and skin panels.

Synchronized Data Acquisition

Real-time integration with MTS test machine (via EtherCAT) for:

Load force tracking (accuracy ±0.5% FS)

Loading frequency synchronization (jitter <1μs)

Continuous data logging at 20 kSPS/channel (24-bit resolution).

Test Protocol

Cyclic pressure loading: Simulated 50,000 flight cycles (equivalent to 20 years of service).

Failure mode detection: Crack initiation/growth monitored via strain field anomalies (Δε ≥ 0.02%).

Key Technological Features

Distributed DAQ Architecture

12 subsystems synchronized via IEEE 1588 Precision Time Protocol (PTP), achieving <5μs inter-unit timing coherence.

Hybrid Signal Conditioning

Simultaneous processing of:

Low-frequency strain signals (DC~10Hz, ±5000με range)

High-frequency dynamic events (up to 5kHz, e.g., buckling transients)

Automated Fatigue Analysis

Rainflow counting & Miner’s rule algorithms applied in real time to predict remaining fatigue life.

Outcome & Significance

Data validation: Test results matched FEM predictions with <8% deviation in critical stress zones.

Design optimization: Identified 3 high-risk areas for structural reinforcement.

Certification support: Provided compliance evidence for CCAR-25.571 (Damage Tolerance and Fatigue Evaluation).

Conclusion

The fatigue loading test successfully demonstrated the durability and damage tolerance of the pressurized cabin over an equivalent 20-year service life. With precise multi-axis strain monitoring and automated fatigue life prediction, the program not only validated FEM models but also identified critical reinforcement zones, ensuring compliance with regulatory standards and enhancing long-term structural reliability.

This test established a benchmark for full-scale aircraft fatigue testing, leveraging high-density distributed sensing and deterministic real-time data fusion.

Key Terms:

MTS integration: Hydraulic test system for applying programmable loads

EtherCAT: Industrial Ethernet protocol for hard real-time control

Rainflow counting: Algorithm for quantifying fatigue cycles from random load histories