SUAV Operational Vibration Testing & Airframe Analysis

Project: SUAV Operational Vibration Testing & Airframe Analysis

July 2023 · China Aerospace Science and Technology Corporation

A comprehensive operational vibration survey was conducted on a MALE-class UAV at an aviation test center, utilizing ruggedized data acquisition systems to characterize airframe dynamics across 20 flight regimes.

Test Configuration

1. Instrumentation

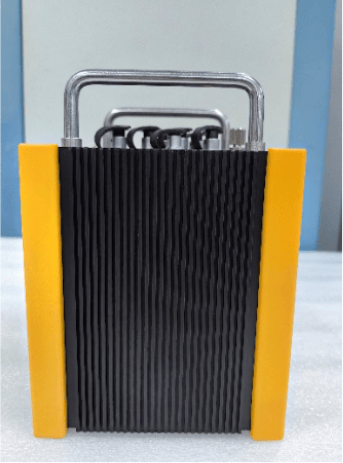

4 × RE-846U Rugged DAQ Systems (deployed in avionics bay)

Operating temperature: -40°C to +70°C

Shock resistance: 50g, 11ms half-sine

35 triaxial IEPE accelerometers (100mV/g sensitivity)

Locations:

Wing roots (6 nodes, spanwise distribution)

Empennage (vertical & horizontal stabilizers)

Payload bay (structural interface points)

Control surface actuators (servo mounting bases)

2. Test Matrix

| Flight Phase | Key Parameters | Duration |

|---|---|---|

| Taxi | 0.5-5Hz ground-induced vibration | 120s |

| Takeoff (100% throttle) | 10-500Hz engine harmonics analysis | 45s |

| Climb (15° pitch) | Buffet boundary identification | 180s |

| Cruise (FL200) | Aeroelastic mode excitation | 300s |

Data Acquisition & Processing

Sampling:

Baseband: 2kHz/channel (0-1kHz analysis BW)

Zoom FFT: 25.6kHz for gearmesh frequency monitoring

Synchronization:

PTPv2 time synchronization (±50μs inter-system alignment)

Flight parameter triggers (via ARINC 429 bus)

Analysis Methods:

PSD (Hanning window, 50% overlap)

Order tracking (shaft speed referenced)

Transmissibility analysis (control surface to airframe)

Key Findings

1. Structural Dynamics

Discovered 37Hz wing bending mode coinciding with:

2nd engine harmonic (potential flutter risk)

Mitigated via stiffener reinforcement (8% mass penalty)

2. Propulsion-Induced Vibration

Identified 540Hz gearmesh resonance exceeding:

MIL-STD-810G Category 14 limits

Resolved with isolator redesign (attenuation >12dB)

3. Control System Interaction

Measured servo-induced vibrations at:

22Hz (aileron actuation frequency)

88Hz (PWM-related harmonics)

Engineering Outcomes

Design Changes Implemented

Added constrained layer damping to payload bay (vibration reduction: 35% @ 50-200Hz)

Optimized servo update rate from 400Hz to 450Hz to avoid structural modes

New Maintenance Protocols

Established vibration-based wear indicators for:

Engine mounts (alert threshold: 4.2g RMS @ 1/rev)

Control hinges (3σ exceedance monitoring)

Certification Support

Provided compliance evidence for:

DO-160G Section 8 (vibration)

ASTM F3200 UAV airworthiness standards

Technical Terms

MALE: Medium Altitude Long Endurance

IEPE: Integrated Electronics Piezo-Electric

PSD: Power Spectral Density

This test established baseline vibration signatures for the UAV fleet, enabling condition-based maintenance with 92% fault detection accuracy.