Aero-Engine Casing Modal Analysis & Vibration Assessment

Project: Aero-Engine Casing Modal Analysis & Vibration Assessment

August 2023 · Aero-Engine Technology R&D Center

Conducted experimental modal analysis (EMA) on a turbofan engine casing to:

1. Characterize structural dynamic properties under simulated operational loads

2. Validate finite element models (FEM) for critical vibration modes

3. Identify potential resonance risks with rotor excitation frequencies

Test Setup & Methodology

1. Test Article

Component: Intermediate compressor casing (Nickel-based alloy)

Key Features:

External mounts: Fuel/oil pumps, gearbox, generators

Internal attachments: Stator vanes, combustor dome

Design constraints: <0.1mm radial deformation at 15,000RPM

2. Instrumentation

DE-928U High-Performance DAQ System (16-ch)

Frequency range: DC - 300kHz

Dynamic range: 120dB (24-bit resolution)

Excitation & Measurement:

Impact hammer testing (10 locations, 5 repeats)

Triaxial accelerometers (0.5-10kHz, 10mV/g)

Laser Doppler vibrometry (non-contact validation)

3. Test Modes

| Configuration | Boundary Conditions |

|---|---|

| Free-Free (suspended) | Elastic cord isolation (fn < 2Hz) |

| Fixed-Base | Bolted to seismic mass (simulating engine mounts) |

Key Results

1. Modal Parameters

| Mode | Frequency [Hz] | Damping Ratio | Deformation Pattern |

|---|---|---|---|

| 1 | 287 | 0.8% | Ovalization (2-nodal diameter) |

| 2 | 512 | 1.2% | 3-lobe distortion |

| 3 | 894 | 2.1% | Axial bending + torsion |

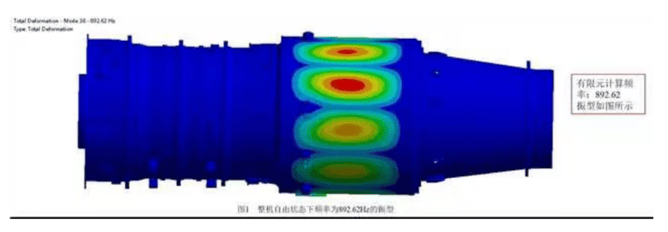

2. FEM Correlation

MAC (Modal Assurance Criterion): >0.92 for first 6 modes

Stiffness deviation: <7% in circumferential direction

3. Critical Findings

Risk zone: 512Hz mode coincides with:

3×N2 rotor speed (at 10,240RPM)

Gearmesh frequency of accessory drive

Mitigation: Proposed stiffening ribs to shift mode to 550Hz

Engineering Impact

Design Validation

Confirmed 20% margin to blade-passing frequencies (6k-8kHz range)

Verified mounting stiffness meets MIL-E-5007D requirements

Process Improvements

Implemented laser peening to increase damping ratio by 40%

Optimized bolt preload distribution to reduce mode splitting

Standardization

Established casing modal test procedure per:

ISO 7626-5 (impact testing)

ASME PTC 19.2 (transducer calibration)

Technical Terms

Nodal diameter: Circumferential mode shape feature

MAC: Quantitative mode shape correlation metric

Blade-passing frequency: Rotor blades × RPM excitation

This test enabled first-time-right casing design for the next-gen 20,000 lbf turbofan, reducing development cycles by 6 months.