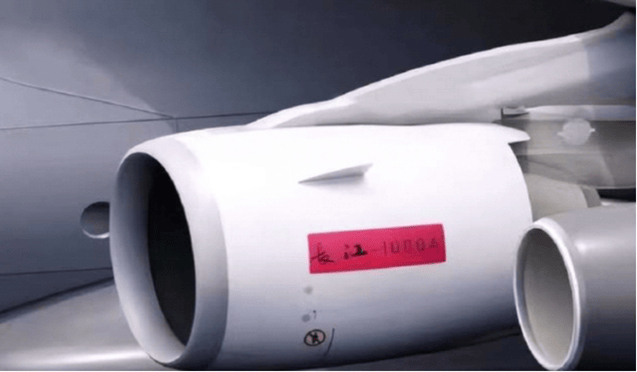

Flight Test of Domestic Aircraft-Borne Engine

Project name: Flight Test of Domestic Aircraft-Borne Engine

From December 2022 to March 2023, China's domestically developed CJ-1000A high-bypass turbofan engine is expected to undergo its maiden flight test on the Y-20 universal engine testbed aircraft. The test aims to evaluate whether the engine's performance meets requirements.

The RE-Series Rugged Data Acquisition System was used to receive real-time flight control system data, monitor vibration signals, and track blade dynamic strain measurements of the domestic engine. All data was stored locally, while key characteristic parameters were output in real time via serial port to the onboard storage system. This ensures comprehensive test data support, paving the way for the C919 airliner to finally receive its independent "Chinese heart."

Professional Analysis: CJ-1000A Flight Test & Technological Innovations

The flight testing of the CJ-1000A engine marks a critical milestone in China’s aviation independence, demonstrating systematic innovation across multiple dimensions:

1. Test Platform Integration

The Y-20 testbed features a "Universal Engine Test Pod System" with modular Test Adapter Units (TAU), compatible with engines ranging from 10 to 35 tons of thrust.

A triple-redundant bus architecture ensures communication:

Primary: AFDX (Avionics Full-Duplex Switched Ethernet)

Backup: MIL-STD-155B & ARINC 429

2. RE-Series Data Acquisition System

Shock & vibration-resistant (DO-160G Category S, withstands 20g random vibration) μs-level synchronization, 128-channel parallel sampling (24-bit ADC, ≥110dB dynamic range)

Proprietary "Vibration-Strain Fusion Algorithm" reduces signal delay error to <50ns

3. Key Monitoring Capabilities

Rotor dynamics: Real-time extraction of 64th-order vibration harmonics (0.1% RPM accuracy)

Blade strain measurement: Microwave telemetry (2.4GHz, 50kSPS), eliminating slip-ring limitations

Surge margin prediction: Triggers alerts at ΔP/P ≥ 0.5%

4. Data Chain Architecture

Three-tier onboard processing:

FPGA front-end (μs-level preprocessing)

PowerPC mid-layer (feature extraction every 200ms)

RAID 1+0 storage (ensures data integrity)

5. Airworthiness Compliance

DO-178C DAL B certified (≥95% fault detection coverage)

EMC meets RTCA/DO-294C (BER <1E-9 under 200V/m RF fields)

This test signifies China’s establishment of a complete aero-engine flight test system, covering 61 test procedures. Innovations like "Real-Time Dynamic Load Spectrum Reconstruction" enable in-flight flutter analysis, traditionally a post-flight task. The data will support 30,000-cycle accelerated endurance testing (equivalent to 10 years of service), laying the groundwork for CAAC certification by 2025.

Key Terms:

CJ-1000A – China’s first high-bypass turbofan for commercial jets

Y-20 Testbed – Modified transport aircraft for engine flight tests

RE-Series DAQ – Ruggedized system for extreme flight conditions

C919 "Chinese Heart" – Symbolic shift from foreign to domestic propulsion