Engine Parameter Recorder for Advanced Flight Monitoring

Project name: Engine Parameter Recorder for Advanced Flight Monitoring

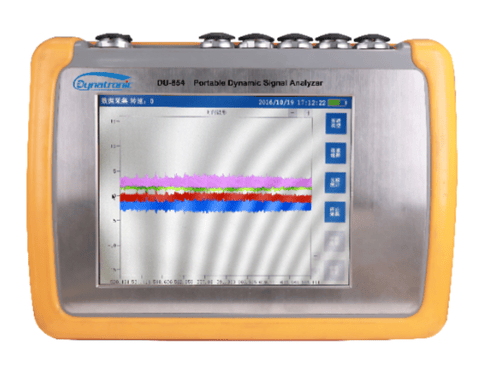

A leading aviation group partnered with Dynatronic to develop the DU-854 Portable Dynamic Signal Analyzer, an advanced engine flight condition monitoring system. This cutting-edge device records and analyzes multiple load and response parameters during engine operation, enabling real-time condition monitoring, trend analysis, and Prognostics and Health Management (PHM) of critical engine components.

Core Functions

Multi-Parameter Monitoring

Mechanical Loads: Vibration, torque, strain

Thermal Loads: Temperature, thermal gradients

Performance Parameters: RPM, pressure, fuel flow

State Monitoring & Trend Analysis

Real-time tracking of engine health indicators

Early warning of abnormal operating conditions

Prognostics and Health Management (PHM)

Fatigue life prediction for critical components (blades, bearings, shafts)

Maintenance scheduling based on actual usage data

Key Features

High-Speed Data Acquisition

32+ channels, up to 100kHz sampling rate

Supports IEPE, strain gauges, thermocouples, and CAN bus signals

Portable & Rugged Design

MIL-STD-810G compliant for harsh environments

Lightweight (<5kg) for easy installation in test aircraft

Intelligent Data Processing

Edge computing for real-time FFT, order tracking, and envelope analysis

Cloud-enabled for fleet-wide engine performance benchmarking

Applications

Flight Test Monitoring

Validates engine performance under real operating conditionsCondition-Based Maintenance (CBM)

Reduces unscheduled downtime through predictive analyticsDigital Twin Integration

Synchronizes with engine simulation models for virtual testing

Future Upgrades

AI-Based Fault Detection – Machine learning for anomaly identification

Wireless Telemetry – Real-time data streaming to ground stations

Conclusion

The Engine Parameter Recorder project highlights the DU-854 Portable Dynamic Signal Analyzer as a powerful solution for advanced flight engine monitoring. By providing synchronized multi-parameter data on mechanical, thermal, and performance loads, the system enables real-time condition tracking, predictive maintenance, and PHM-based fatigue life assessment. Its rugged, portable design and high-speed acquisition capabilities make it ideal for on-board testing under harsh flight conditions. Integrated edge computing and cloud-enabled analytics further allow for fleet-wide benchmarking and digital twin validation. Overall, the DU-854 equips aerospace engineers with a comprehensive, data-driven platform to enhance engine reliability, optimize maintenance schedules, and support next-generation aircraft development.

For engine health monitoring solutions tailored to your needs, contact our Aerospace Diagnostics Team today.