1500-Channel Integrated Data Acquisition System

Project: 1500-Channel Integrated Data Acquisition System

Based on the requirements of a research institute's 1500-channel strain and displacement data acquisition system, Dynatronic provides a comprehensive, integrated large-scale system solution. This system is used for strain, displacement, and other measurements and monitoring during experiments, with its measurement results serving as critical evidence for structural strength test analysis and evaluation. Measurement accuracy directly impacts the quality of the tests.

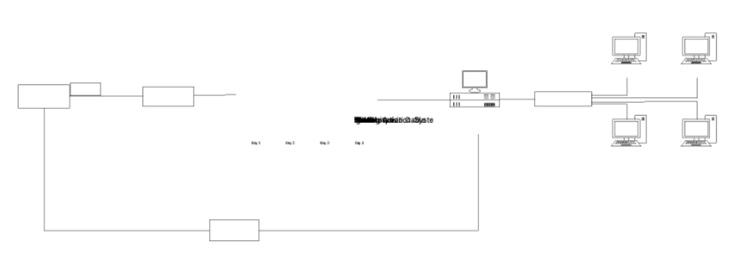

The data acquisition system consists of:

A 1500-channel data acquisition system (comprising 12 × 128-channel SE-98

centralized data measurement and analysis systems)

A synchronized clock system

A control computer

Data cables

Data acquisition, analysis, and processing software

The entire system adopts a hybrid centralized and distributed architecture. The chassis uses a standard 19-inch rack-mounted structure, housed in a professional shielded cabinet that integrates the data acquisition platform, signal conditioning platform, high-precision programmable power supplies, network switches, and other equipment.

The system is configured with all necessary testing equipment except sensors. The connections between sensors and the acquisition cabinet utilize multi-core, high-performance, low-noise shielded cables to minimize interference from field wiring and ensure strong anti-interference capability.

System Features

Client/Server (C/S) Architecture & Multi-Client Support

Multiple computers on the same LAN can run the software platform with different roles:

Master Controller (full system control, parameter configuration, data storage)

Data Server

Clients (data display, analysis, and selective local storage)

Designed for large-scale experiments (e.g., wind tunnel tests, full-aircraft strength tests)

Clients can filter and selectively transfer specific channel data while storing it locally.

The number of clients can be adjusted based on network bandwidth limitations.

Synchronization with MTS Loading Systems

Ensures precise coordination between data acquisition and mechanical loading.

Dynatronic Software Suite

Supports continuous recording and variable sampling rates (high-speed & low-speed).

Meets multi-condition test requirements, including continuous recording during loading and high-speed snapshot capture during stable loading conditions.

Hierarchical System Architecture

Hardware Layer

12 × SE-98 distributed acquisition nodes (128 ch/node), PXIe backplane (≥8 GB/s bandwidth)

Synchronization: OCXO oven-controlled oscillator (±0.01 ppm), IEEE 1588v2 (<100 ns sync error)

Signal conditioning: Programmable gain amplifier (PGA 1-10,000×), 24-bit Σ-Δ ADC, 10V excitation

Network Layer

10G industrial Ethernet with PRP redundancy (zero failover time)

Double-shielded SSTP cables (<3 dB/100m @100 MHz loss)

Software Layer

Real-time OS (RTOS) kernel (<1 ms latency)

Time-series database (supports 10 MS/s/ch sustained write)

Client-side data streaming (H.264 video + sensor sync)

2. Key Innovations

Dynamic Sampling

Auto-switching between 10 kHz (high-speed) and 1 Hz (low-speed) based on MTS load rate (ΔF/Δt)

FPGA triggering (<5 μs response)

Anti-Interference Technology

3-stage filtering:

Analog EMI filter (CMRR >120 dB @60 Hz)

Digital FIR (programmable cutoff)

Adaptive software notch

Channel isolation >90 dB @1 kHz

Distributed Storage Optimization

RDMA-based protocol (40% lower CPU usage)

Local SSD buffering (2 TB/node) with offline recovery

3. Performance Validation

Aircraft static load test results:

72-hour continuous operation (zero data loss)

MTS sync error <50 μs

Strain linearity: 0.05% FS

Client display latency <200 ms (1,000 ch)

The modular design allows expansion to 3,000 channels, with IEEE 802.3bt PoE++ support for remote signal conditioning. The system complies with ASTM E1942-18 (highest precision class for structural testing).