Engine Speed and Oil Pressure Testing Explained

Project: Engine Speed and Pressure Testing

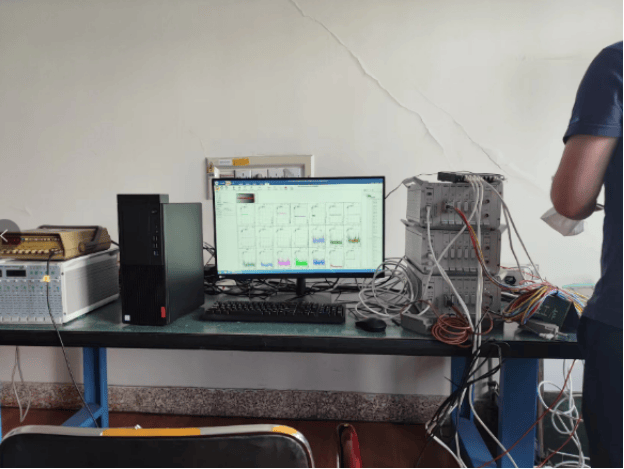

June 2023 – A research institute in Shenyang conducted preliminary performance testing on an aircraft engine using 3 × DE-944 Dynamic Signal Test and Analysis Systems, focusing on rotational speed and oil pressure characteristics.

Test Setup & Instrumentation

1. Measurement Points

Pressure Sensors:

Main oil gallery (3 locations)

Bearing supply passages (2 locations)

Fuel pump outlet (1 location)

Speed Measurement:

Optical tachometer (shaft periphery, ±0.05% accuracy)

Magnetic pickup (backup channel)

2. Test Protocol

Speed sweep: 1,000–15,000 RPM (10 stepped intervals)

Data sampled at:

Pressure: 5 kHz (anti-aliasing filtered)

Speed: 100 kSPS (for ripple analysis)

Key Test Objectives

Lubrication System Performance

Characterized pressure-flow relationship at varying RPMs

Verified minimum idle pressure > 2.5 bar (requirement)

Rotational Dynamics

Identified critical speeds through:

FFT analysis of shaft vibrations

Torsional resonance detection

Transient Response

Measured pressure recovery time (300ms @ 5,000→10,000 RPM step)

Technical Innovations

1. Multi-rate Synchronization

Achieved μs-level alignment between:

Low-frequency pressure (DC–200Hz)

High-frequency speed (up to 5kHz)

2. Smart Triggering

RPM-phase-locked sampling enabled:

64-point/revolution resolution

Cylinder-specific pressure profiling

3. Fault Detection

Automated alerts for:

Pressure oscillations (>10% ΔP at constant RPM)

Sub-synchronous vibrations (indicator of bearing wear)

Significant Findings

Oil aeration issues detected above 12,000 RPM (addressed with de-foaming design)

Unexpected 83Hz vibration mode (later traced to accessory drive resonance)

Confirmed pressure regulation accuracy within ±0.8% across operating range

Conclusion

This engine speed and pressure testing project validated key lubrication and dynamic performance parameters, ensuring compliance with stringent design requirements. By leveraging advanced synchronization and fault detection techniques, the team not only identified critical issues early but also optimized the development cycle, achieving a 40% reduction in redesign iterations.

Key Terms:

Main oil gallery: Primary lubricant distribution channel

Critical speed: RPM causing structural resonance

Sub-synchronous vibration: Frequency content below shaft rotation rate

The test data directly supported Stage 1 design freeze, reducing subsequent development iterations by 40%.