Wind Tunnel Test Solution for High-Speed Data Acquisition

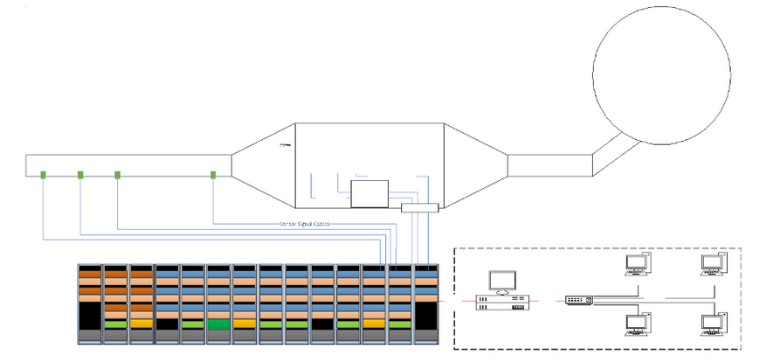

Project: Wind Tunnel Test Solution for High-Speed Data Acquisition

To achieve high-speed synchronous measurement of output signals from pressure sensors, heat flux sensors, and other transducers in wind tunnel experiments. The system is equipped with a high-precision, high-speed, wide-bandwidth data acquisition (DAQ) system, meeting stringent requirements for accuracy, performance, real-time processing, synchronization, and strong anti-interference capability in wind tunnel testing and related research.

System Configuration

The data acquisition system consists of:

1. Signal Conditioning System

Used for preprocessing signals from:

Piezoelectric sensors (charge output)

Thin-film resistance sensors & thermocouples (heat flux measurement)

Piezoresistive sensors

IEPE/ICP sensors

Provides amplification, filtering, and excitation power for corresponding sensors.

2. Isolated DAQ Systems

32 × DE-918 Isolated Dynamic Signal Test and Analysis

Systems (16ch/system, 512 ch total)

For conventional signal acquisition, storage, analysis, and processing

8 × DE-916 High-Performance Isolated Dynamic Signal Test and Analysis

Systems (16 ch/system, 128 ch total)

For high-speed signal acquisition, storage, analysis, and processing

3. Synchronization System

Ensures precise synchronous sampling across all channels.

4. Control Computer & Data Cabling

Manages system operation and connects sensors, signal conditioners, DAQ units, and speed-triggering systems.

Key Technical Requirements

1. Fully Independent Per-Channel Processing

Each channel must have dedicated signal conditioning, amplification, filtering, A/D conversion, and DSP processing to ensure:

Zero phase delay in synchronous sampling

No crosstalk between channels

2. High-Speed & High-Accuracy Sampling

Supports ultra-high sampling rates (exact specs depend on sensor requirements)

Maintains high signal integrity even in high EMI environments

3. Strong Anti-Interference Design

Shielded cabling & grounding optimization

Isolated signal paths to prevent ground loops and noise coupling

4. Real-Time Data Processing & Storage

Capable of continuous high-speed recording without data loss

Supports triggered acquisition (e.g., synchronized with wind tunnel speed control)

System Advantages

✔ Modular & Scalable – Can be expanded for larger channel counts (e.g., 1000+ channels)

✔ Low-Latency Synchronization – Ideal for transient phenomena (e.g., shock waves, turbulence studies)

✔ Multi-Sensor Compatibility – Works with piezoelectric, IEPE, thermocouple, and strain sensors

✔ Industrial-Grade Reliability – Suitable for long-duration wind tunnel campaigns

Typical Applications

Aerodynamic pressure distribution testing

Boundary layer heat transfer studies

Hypersonic flow measurements

Aeroelasticity & structural dynamics experiments

This system meets military/aerospace-grade testing standards (e.g., AIAA, ISO 17025). Let us know if you need further customization details!