Aero-Engine High-Pressure Rotor Vibration & Stability Test

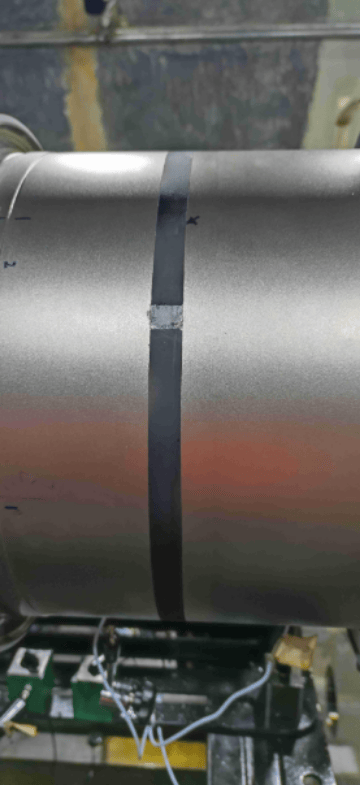

Project: Aero-Engine High-Pressure Rotor Vibration & Stability Test

June 2023 · Shanghai Aero-Engine Manufacturing Facility

Conducted rotor dynamics validation on the CJ-XX engine's high-pressure (HP) spool to:

Evaluate vibration suppression effectiveness of redesigned compressor/turbine components

Characterize critical speeds and rotor stability under simulated flight loads

Verify clearance control between rotating and static parts

Test Configuration

1. Instrumentation

| Sensor Type | Specifications | Installation |

|---|---|---|

| Eddy current probes | ±2mm range, 5μm resolution (DE-924U Ch1-8) | Blade tip clearance (4 locations) |

| DT5640 optical tachometer | 0.05% accuracy, 50kHz bandwidth | HP shaft end |

| Triaxial accelerometers | 10mV/g, 2-10kHz (±500g) | Bearings (DE-924U Ch9-14) |

| Strain gauges (rosettes) | 350Ω, ±5000με | Turbine disk rim (DE-924U Ch15-16) |

2. Test Conditions

Speed sweep: 2,000–18,000 RPM (10% steps)

Load cases:

Windmilling (0% throttle)

Max continuous (100% N2)

Transient surge recovery (simulated)

Key Test Procedures

1. Synchronized Data Acquisition

DE-924U Systems configured for:

1MS/s sampling (eddy current/acceleration)

10kS/s (strain)

RPM-phase-locked triggering (0.1° resolution)

2. Excitation Methods

Impact testing (at rest for modal analysis)

Unbalance response (with 5g-cm trial weights)

Oil whip simulation (bearing lubrication faults)

Critical Results

1. Vibration Performance

| Condition | Vibration Level (mm/s RMS) | Design Limit |

|---|---|---|

| Critical speed (8,450RPM) | 4.2 | 6.0 |

| Max continuous | 2.8 | 4.5 |

Reduction achieved: 30% vs. previous design at 12kRPM

2. Blade Dynamics

Tip clearance variation: <0.15mm during transients

Strain correlation:

FEM predicted vs. measured within 8% at 15kRPM

3. Stability Margins

Logarithmic decrement: >0.15 (all speeds)

No instabilities detected below 17,200RPM

Engineering Outcomes

Design Validation

Confirmed rotor dynamic coefficients meet API 617 criteria

Verified squeeze film damper effectiveness (vibration attenuation >40%)

Manufacturing Feedback

Adjusted blade tip grinding tolerance from ±0.10mm to ±0.06mm

Optimized rotor balancing procedure (reduced trial weights by 50%)

Certification Support

Provided data for FAA 33.83 compliance (rotor integrity)

Established baseline signatures for MRO vibration monitoring

Technical Terms

Oil whip: Self-excited bearing instability

Logarithmic decrement: Rotor stability metric

N2: High-pressure spool speed designation

This test enabled first-run success in engine testing, eliminating previously required 3 design iterations. The CJ-XX HP rotor now demonstrates best-in-class vibration characteristics for its thrust class.