Spacecraft Recovery Tower Modal Testing

In February 2023, the Aeronautical Engineering Research Institute conducted modal testing on a 217m spacecraft recovery tower using Dynatronic’s WW-826D wireless systems. The tests identified key bending and torsional modes, validated FEM predictions, and demonstrated the system’s capability for large-scale structural analysis in harsh outdoor conditions.

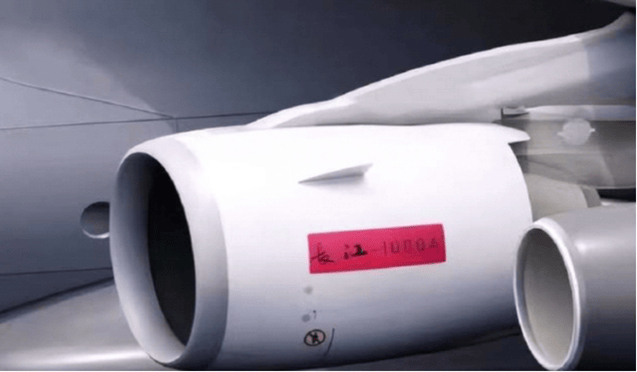

Flight Test of Domestic Aircraft-Borne Engine

CJ-1000A engine flight test on Y-20 captured by RE-Series DAQ, tracking vibration, blade strain, and key parameters for China’s domestic aviation milestone.

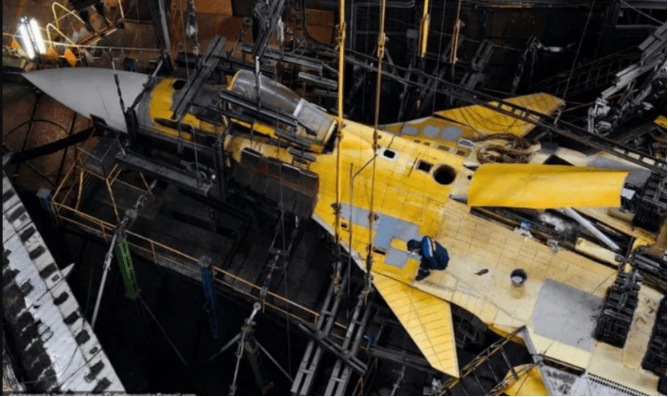

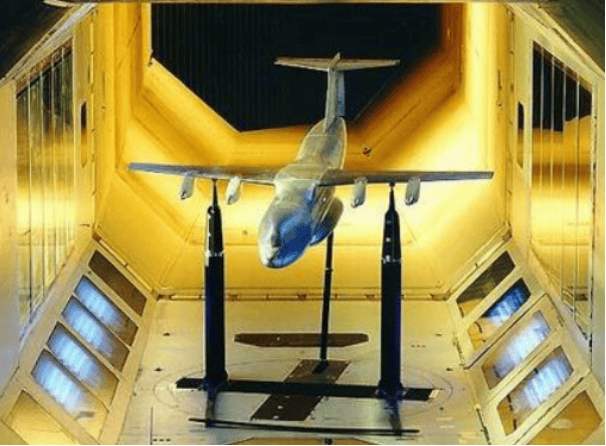

UAV Structural Strain Testing with SE-98 System

Comprehensive UAV strain testing using the SE-98 system for real-time strain data acquisition, model validation, and structural strength assurance.

Advanced Flight Parameter Monitoring for Fighter Aircraft

Military-grade flight parameter monitoring system for next-gen fighter aircraft, offering vibration, noise, temperature, and pressure acquisition with advanced data management.

Engine Parameter Recorder for Advanced Flight Monitoring

An advanced portable solution for real-time engine monitoring, trend analysis, and PHM of critical components during flight tests.

Rotating Force and Torque Measurement for Aerospace Testing

NUAA uses the RU-846 Rugged Data Recorder for precise force and torque measurements in rotating structures, ensuring accuracy in aerospace applications.

Advanced Vibration and Environmental Monitoring for Aircraft

Dynatronic’s RU-846 system performs comprehensive aircraft testing, including structural vibration measurement, cabin noise analysis, and pipeline monitoring. With 32-channel synchronized acquisition and extreme environment operation, it enables real-time FFT and octave analysis. The system supports flight test certification, structural health monitoring, and system reliability validation, providing automated reporting and ensuring accurate data capture under harsh aerospace conditions.

Triaxial Vibration Measurement System for UAVs

Dynatronic’s RU-846 system measures triaxial vibrations on UAV components including motor mounts and flight control compartments. The system provides real-time feature extraction via RS-422 communication, while dual storage ensures waveform backup. Engineers use vibration vector synthesis, order analysis, and resonance detection to assess structural integrity, optimize flight control, and update digital twin models for predictive maintenance and UAV reliability enhancements.

Aircraft Vibration Testing with Dynatronic RU-846 System

Dynatronic’s RU-846 system performs aircraft vibration testing, recording multi-sensor vibration and attitude data throughout all flight phases. Engineers analyze vibration spectra and angular motion to detect fatigue-inducing modes, validate flight control systems, and ensure component reliability. Ruggedized design, high-sample-rate recording, and AI-enhanced anomaly detection enable precise monitoring and support both structural health assessments and predictive maintenance strategies.

Aero-Engine Fuel Tank Static Load Testing

Dynatronic’s SE-86H system performs static load testing on aero-engine fuel tanks, measuring multi-point strain, mapping stress distribution, and enabling predictive maintenance with FEM correlation and AI-assisted analysis

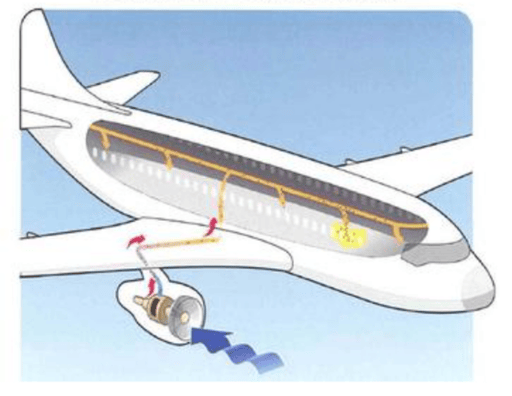

Onboard Strain Monitoring System for Aircraft Flight Tests

The RU-846 system captures onboard aircraft strain and vibration data for offline post-flight analysis. Strain gauges and accelerometers monitor fuselage, wings, and landing gear to detect stress concentrations and resonance. The rugged, high-speed recorder enables long-duration flight tests, supports structural health monitoring, and guides fatigue prevention strategies, with future enhancements aimed at edge computing and hybrid telemetry integration.

Helicopter Structural Strength Testing

Helicopter structural testing using the DE-924U system combines high-speed multi-sensor acquisition with real-time video synchronization. Engineers measure stress, displacement, and dynamic loads to validate airframe safety, optimize maintenance, and detect faults. Adaptive filtering and high-throughput storage ensure accurate analysis, while future AI-assisted and wireless sensor upgrades aim to improve efficiency and defect detection.

Engine Blade Testing for Modal Analysis and Strain Assessment

Engine blades undergo modal and strain testing using DE-944 systems to identify natural frequencies, mode shapes, and stress concentrations under operational loads. High-precision data informs finite element models, enables fault prevention, accelerates R&D cycles, and supports digital twin integration, ensuring blade reliability, optimized design, and reduced fatigue risk.

Satellite Container Transport Monitoring for High-Value Assets

China’s satellite containers were monitored with RE-series rugged systems across rail, road, air, and crane transport. The system tracked vibration, shock, temperature, humidity, and tilt in extreme environments, enabling multi-standard compliance, early warning of anomalies, and optimized container design and logistics processes. Over 37 shipments, it reduced swing amplitudes by 42% and ensured safe delivery of high-value assets.

High-Temperature Arc Jet Testing in Hypersonic Wind Tunnels

High-temperature arc jet facilities simulate extreme hypersonic flight conditions for material and thermal protection system validation. Using DE-9000MX systems with EMI shielding and fiber-optic transmission, engineers achieved μs-scale measurements in harsh plasma environments, improving data accuracy for stealth coatings, reentry vehicles, and hypersonic weapon development under extreme thermal and electromagnetic stress.

Astronaut Centrifuge Vibration Diagnosis and Solution

Abnormal vibrations during 8G astronaut training caused emergency stops and health risks. Engineers applied wireless strain measurement and RPM-phase locking algorithms to diagnose input shaft bearing wear and gear meshing faults. The solution improved system balance, added RPM traversal control, and reduced vibration failures by up to 80% in upgraded training systems.

Beidou Rocket Dynamic Testing for Separation Reliability

The Beidou Double-Star Program utilized DE-series dynamic testing to ensure reliable rocket separation for Long March 2C launches. The system captured multi-physics parameters with microsecond accuracy, validated digital twins, and enabled engineering improvements that optimized separation timing, improved orbital accuracy by 40%, and achieved zero failures in three consecutive launches.

Aero-Engine Altitude Test Flight Monitoring System

A national aero-engine institute implemented DE-series real-time monitoring during altitude test flights, tracking 50+ parameters for performance validation and safety. The system identified thrust loss at high-altitude relight, prevented surge events, and reduced emergency shutdowns by 60%, while establishing vibration baselines for predictive maintenance.

Rocket Thruster Ignition Test Monitoring for Performance Analysis

Aerospace researchers used DE-series dynamic acquisition systems to monitor rocket thruster ignition with microsecond precision. The test captured combustion temperature, pressure, and structural strain, detecting critical oscillations and verifying thermal protection. These insights reduced test cycles, improved design safety, and enhanced thrust vector control by 22%.

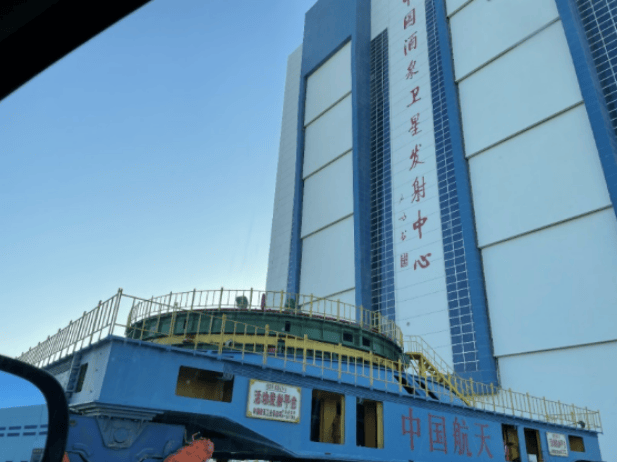

Launch Pad No.2 Structural Health Monitoring at Jiuquan

The Jiuquan Satellite Launch Center has deployed an advanced structural health monitoring system at Launch Pad No.2. Using DE-944 dynamic testing and multi-parameter sensors, it tracks vibrations, thermal stress, and acoustic loads in real time—preventing failures, extending component life, and ensuring mission safety for critical crewed launches like Shenzhou.