Rocket Thruster Ignition Test Monitoring Performance

Project name: Rocket Thruster Ignition Test Monitoring

A national aerospace research institute deployed DE-series dynamic signal acquisition systems to conduct comprehensive performance evaluation during rocket thruster ignition tests, capturing critical parameters with microsecond-level precision.

1. Test Configuration

| Parameter | Sensor Type | Measurement Range | Sample Rate |

|---|---|---|---|

| Combustion Temperature | K-type Thermocouple Array | 0-2500°C | 1kHz |

| High-g Acceleration | Piezoelectric Accelerometer | ±5000g | 50kHz |

| Chamber Strain | High-Temperature Strain Gauge | ±5000με | 10kHz |

| Internal Pressure | Dynamic Pressure Transducer | 0-20MPa | 100kHz |

| Nozzle Displacement | Laser Vibrometer | ±10mm @ 0.1μm resolution | 200kHz |

2. Key Test Objectives

Combustion Stability Analysis

Detect high-frequency pressure oscillations (50-5000Hz)

Characterize thermo-acoustic coupling effects

Structural Integrity Verification

Monitor real-time strain propagation in chamber walls

Identify potential buckling modes during start-up transients

Performance Benchmarking

Correlate measured thrust with CFD predictions

Validate ignition sequence timing (T±0.5ms accuracy)

3. System Implementation

DE-Series High-Speed System Features:

256 isolated channels with 24-bit resolution

Synchronization with optical ignition trigger (jitter <1μs)

Custom blast-proof enclosure (withstands 150dB SPL)

Data Acquisition Strategy:

Pre-ignition Baseline (10s @ 1kHz)

Ignition Phase (0-2s @ max rate)

Steady-State (30s @ adaptive sampling)

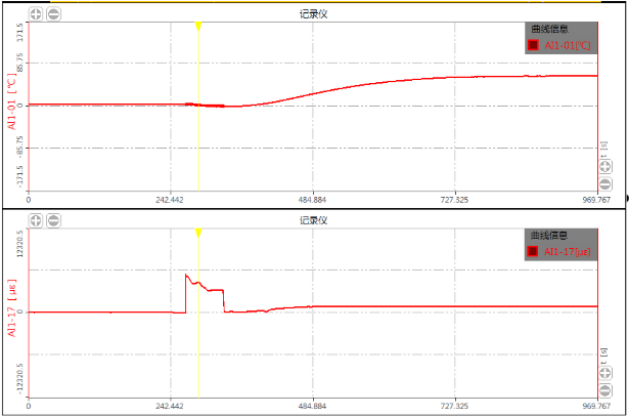

4. Critical Findings

Combustion Instability Detection:

Identified 287Hz pogo oscillation during 85% throttle

Resolved through injector plate redesign (damping increased by 40%)

Thermal Protection Validation:

Recorded 1800°C wall temperature gradient

Confirmed ablation coating performance within specs

5. Operational Benefits

Test Efficiency

Reduced hot-fire test iterations by 35% through comprehensive data capture

Failure Prevention

Early detection of injector cracking saved $2.8M in potential hardware loss

Design Optimization

Improved thrust vector control response by 22% via nozzle dynamics analysis

Conclusion

The Rocket Thruster Ignition Test Monitoring System by Dynatronic has significantly advanced the precision and reliability of rocket engine testing. By integrating high-speed data acquisition with microsecond-level precision, the system enables comprehensive performance evaluation during ignition tests. Key features include synchronized multi-parameter measurement, real-time combustion stability analysis, and structural integrity verification. The system has led to notable improvements, such as a 35% reduction in hot-fire test iterations and a 22% enhancement in thrust vector control response. Additionally, early detection of potential failures has resulted in substantial cost savings, exemplified by the prevention of $2.8 million in hardware loss due to injector cracking. This system exemplifies Dynatronic's commitment to providing cutting-edge solutions for the aerospace industry, ensuring optimized performance and safety in rocket propulsion systems.