Advanced Vibration and Environmental Monitoring for Aircraft

Project name: Advanced Vibration and Environmental Monitoring for Aircraft

Overview

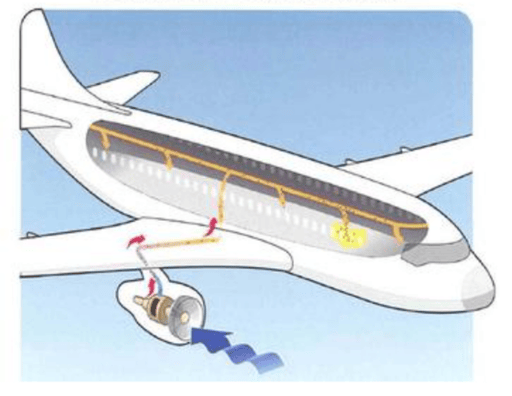

AVIC Research Institute has deployed Dynatronic's customized RU-846 Rugged Data Recorder for comprehensive aircraft testing.

System is designed to capture multiple parameters simultaneously, providing engineers with accurate structural, acoustic, and environmental data.

Applications include flight certification, structural health monitoring, and system reliability validation.

Structural Vibration Measurement

Monitors wing and empennage vibrations with ±200g measurement range and 0–5kHz bandwidth.

Enables modal analysis to identify natural frequencies and detect flutter onset.

Supports fatigue assessment of critical structural components.

Allows correlation of vibration signatures with flight conditions and environmental factors.

Cabin Noise Analysis

Measures sound pressure levels ranging from 30–140dB.

Frequency spectrum analysis aids in NVH (Noise, Vibration, Harshness) optimization.

Supports comfort and safety assessments for crew and passengers.

Provides real-time monitoring during various flight conditions including takeoff, cruise, and landing.

Pipeline and System Monitoring

Pressure measurement: 0–10MPa range, 0.1% full-scale accuracy.

Temperature monitoring: -40°C to +300°C for hydraulic and fuel systems.

Detects anomalies in aircraft pipelines, helping prevent potential failures.

Synchronized with vibration and noise measurements for holistic system evaluation.

Key Features

Synchronized Multi-parameter Acquisition

32-channel simultaneous sampling at 100kHz.

Supports IEPE, voltage, and thermocouple inputs.

Ensures precise time alignment across all sensors.

Extreme Environment Operation

Rugged MIL-STD-810G compliant design.

Operates reliably between -40°C and +85°C.

Resistant to shock, vibration, and EMI interference.

Intelligent Data Processing

Real-time FFT, octave, and statistical analysis.

Automated report generation and post-test evaluation.

Supports correlation with digital twin and predictive maintenance models.

Applications and Benefits

Flight test certification and structural verification.

Continuous structural health monitoring during operational flights.

System reliability validation for critical aircraft subsystems.

Improved safety, performance, and design feedback for next-generation aircraft.

Conclusion

The RU-846 system provides high-precision, synchronized multi-parameter monitoring for aircraft testing.

Its rugged design, real-time processing, and environmental adaptability make it ideal for both flight certification and research applications.

By integrating structural, acoustic, and pipeline data, engineers gain a complete understanding of aircraft performance, enabling safer, more reliable, and optimized designs.