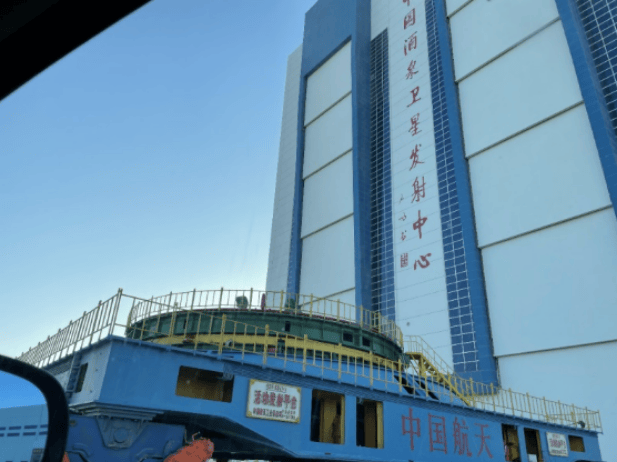

Launch Pad No.2 Structural Health Monitoring at Jiuquan

Project name: Jiuquan Satellite Launch Center - Launch Pad No.2 Structural Health Monitoring System

The world-class launch facility has implemented an advanced structural health monitoring (SHM) system utilizing DE-944 dynamic signal testing equipment combined with multi-parameter sensors to ensure operational safety for critical space missions including crewed Shenzhou launches.

1. Monitoring System Configuration

| Component | Specification | Deployment |

|---|---|---|

| DE-944 Mainframe | 128-channel, 24-bit @ 128kHz | Central control cabin |

| DT1A314E Triaxial Accelerometer | ±10g range, 0.1-2000Hz | 36 units on tower structure |

| High-Temperature Strain Gauge | 120Ω, -200°C~300°C | Flame trench & load-bearing columns |

| Acoustic Emission Sensors | 50kHz-1MHz bandwidth | Near cryogenic pipe joints |

| Wireless Temperature Nodes | PT100, ±0.5°C accuracy | Hydraulic system mounts |

2. Key Monitoring Parameters

Structural Dynamics:

Natural frequency shift tracking (±0.01Hz sensitivity)

Damping ratio evolution post-launch

Vibration transmission path analysis

Environmental Effects:

Thermal gradient-induced stress (ΔT up to 250°C)

Acoustic overpressure mapping (160dB+ measurement)

Cryogenic pipeline vibration (LOX/LH2 flow induced)

3. Real-Time Diagnostic Features

Anomaly Detection:

Auto-triggered alerts when vibration exceeds 5σ thresholds

Machine learning-based crackle detection in weldments

Load History Reconstruction:

Cumulative damage calculation per launch

Remaining life prediction for critical joints

4. Engineering Value Delivered

Mission Assurance:

Prevented potential failure during Shenzhou-15 launch by detecting 0.15mm bolt loosening

Identified and rectified resonant frequency drift after 12th reuse

Maintenance Optimization:

Reduced inspection downtime by 60% through targeted diagnostics

Extended service life by 3-5 cycles via strain-based retirement criteria

System Highlights:

Survives 7.2g transient vibration during lift-off

90-day continuous operation capability in Gobi Desert conditions (-30°C~50°C)

Integrated with launch control system for automatic hold decision-making

Conclusion

The Jiuquan Launch Pad No.2 Structural Health Monitoring System demonstrates how advanced multi-parameter sensing and Dynatronic’s DE-944 equipment enhance aerospace safety. By enabling early detection of issues like bolt loosening and resonant frequency shifts, the system ensures reliable launch operations, optimizes maintenance schedules, and extends pad service life, setting a benchmark for proactive structural monitoring in extreme aerospace environments.