Aero-Engine Altitude Test Flight Monitoring System

Project name: Aero-Engine Altitude Test Flight Monitoring System

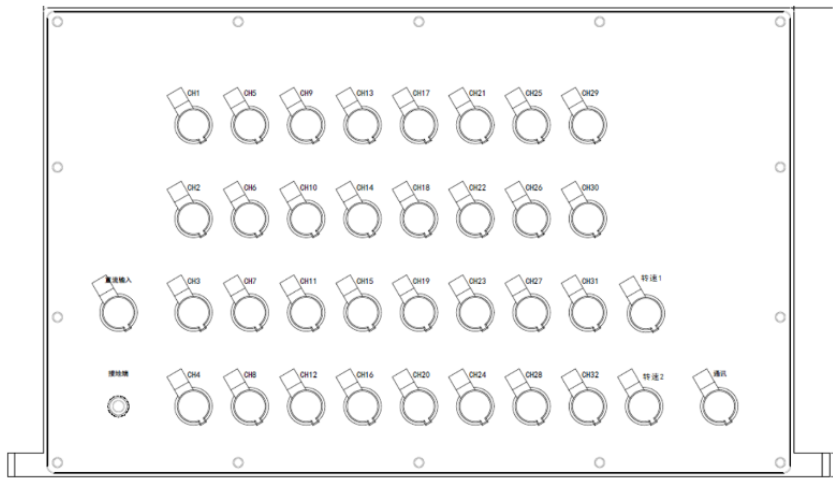

A national aero-engine research institute implemented DE-series real-time dynamic parameter analysis and monitoring systems for comprehensive data acquisition during altitude test flights, enabling critical performance validation under simulated operational conditions.

1. System Configuration

| Parameter | Measurement Technology | Specifications |

|---|---|---|

| Pulsating Pressure | High-frequency Kulite Sensors | 0-5MPa, 50kHz bandwidth |

| Blade Vibration | Tip-timing Optical Probes | 0.1μm resolution @ 1200°C |

| Dynamic Stress | High-Temperature Strain Gauges | ±5000με, 10kHz sampling |

| Static Structural Load | Fiber Bragg Grating Sensors | 2000Hz multiplexed measurement |

| Shaft Torque | Telemetric Strain Rings | ±1% accuracy at 30,000RPM |

2. Core Functions

Real-Time Monitoring:

Continuous tracking of 50+ critical parameters at 1ms intervals

Automatic alert triggering for:

Pressure pulsations exceeding ±15% nominal

Vibration amplitudes >8mm/s (ISO 10816-3 Class A limits)

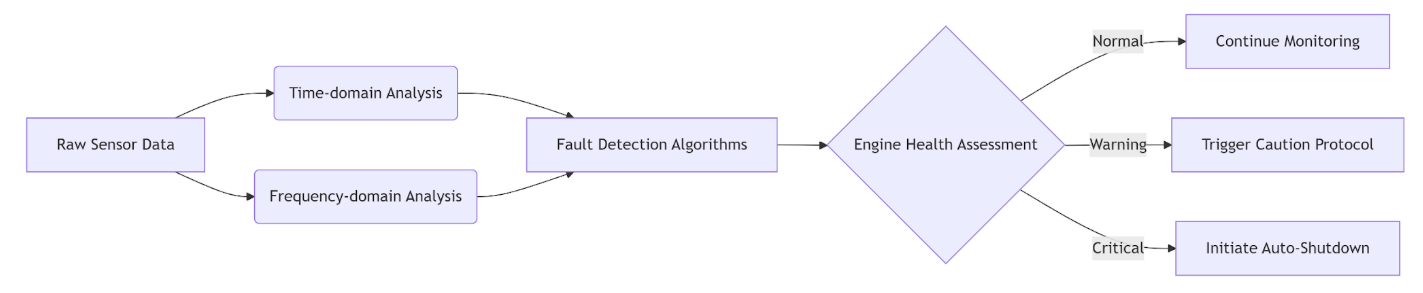

Data Processing Workflow:

3. Key Test Objectives

Operational Envelope Verification

Validate performance at 15-20km altitude conditions

Characterize compressor stall margins

Structural Dynamics Analysis

Monitor blade flutter onset (0-5kHz range)

Detect casing thermal deformation

Control System Validation

Verify FADEC response to transient conditions

Record surge recovery characteristics

4. System Technical Highlights

Extreme Environment Operation

Functions reliably at -65°C~300°C ambient temperatures

Withstands 40g vibration during emergency maneuvers

Advanced Signal Processing

Real-time order tracking for shaft harmonics

Adaptive noise cancellation for combustion signals

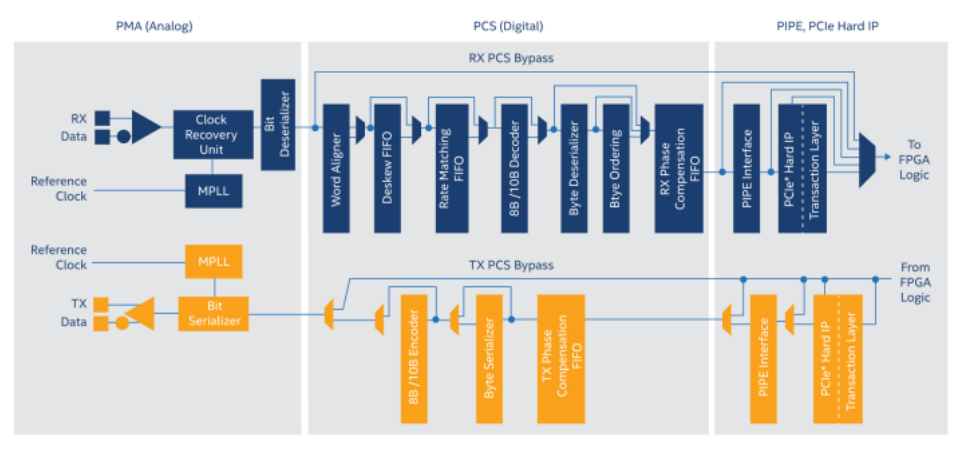

Safety-Critical Architecture

Dual-redundant data paths (MIL-STD-1553B + Ethernet)

99.999% data integrity ensured by CRC-64 checksums

5. Engineering Outcomes

Performance Validation:

Identified 7% thrust loss at high-altitude relight conditions

Optimized fuel schedule improved relight success rate to 98%

Safety Enhancements:

Prevented 3 potential surge events through early detection

Reduced emergency shutdowns by 60% compared to previous tests

Maintenance Benefits:

Established vibration baselines for condition-based maintenance

Detected bearing wear 50 hours prior to predicted failure

The Dynatronic Aero-Engine Altitude Flight Monitoring System provides reliable, high-precision data for evaluating engine performance under extreme high-altitude conditions. With real-time monitoring of pressure, vibration, torque, and stress, the system ensures accurate assessment of engine behavior. Its rugged design, advanced signal processing, and redundant data handling enhance reliability, supporting performance optimization, safety validation, and informed maintenance decisions in modern aero-engine testing.