Engine Blade Testing for Modal Analysis and Strain Assessment

Project name: Engine Blade Testing for Modal Analysis and Strain Assessment

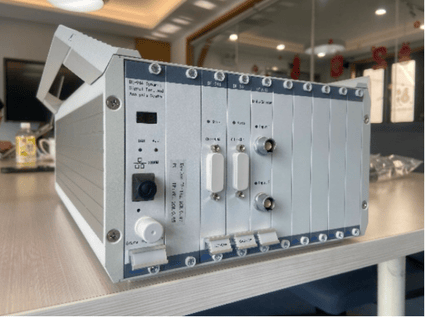

A certain engine research institute utilizes the DE-944 Dynamic Signal Test and Analysis System for engine blade modal testing and strain strength testing.

1. Overview of Testing Content

Modal Testing

By exciting the blade (impact hammer/shaker) and measuring its dynamic response, the natural frequencies, mode shapes, and amping ratios are identified to avoid resonance with engine excitation frequencies during operation.Strain Strength Testing

Measures the strain distribution on the blade surface under static/dynamic loads (centrifugal force, aerodynamic force, thermal load) to assess stress concentration areas and fatigue risks.

2. Core Functions of the DE-944 System

Multi-Channel Synchronized Acquisition

Supports synchronous data acquisition from accelerometers, strain gauges, laser vibrometers, and other sensors, ensuring spatiotemporal consistency in modal and strain data.High-Precision Dynamic Signal Analysis

Provides FFT, order analysis, modal parameter identification (e.g., ERA algorithm), and other functions to accurately extract blade dynamic characteristics.Real-Time Monitoring & Visualization

Displays real-time strain cloud maps and animated mode shapes for rapid anomaly detection in vibration or stress concentration.

3. Key Steps in the Testing Process

Sensor Placement

Modal Testing: Accelerometers are attached at key points, or non-contact laser vibrometry (VibroMicro VM-S-100) is used.

Strain Testing: Strain gauges are applied to stress-sensitive areas (e.g., blade root, leading edge) with temperature compensation.

Excitation Methods

Impact hammer (transient excitation) for lab-based modal analysis.

Shaker (sine sweep/random excitation) for closer simulation of real operating conditions.

Data Acquisition & Analysis

The DE-944 system records frequency response functions (FRF) or strain time-domain signals.

Built-in software (e.g., modal analysis module) performs parameter identification and mode shape reconstruction.

4. Technical Challenges & Solutions

High-Temperature Effects

High-temperature strain gauges (e.g., ceramic-based) or infrared thermography are required for thermal correction.Rotational State Testing

For rotating conditions, slip rings or telemetry systems transmit signals, requiring DE-944 to support high-speed wireless acquisition.Signal Noise Suppression

Anti-aliasing filters and coherence function analysis eliminate environmental noise interference.

5. Application Value

Design Optimization: Modal data refines finite element models, guiding blade geometry/material improvements.

Fault Prevention: Detects abnormal vibrations or excessive stress to prevent fatigue failure.

Reduced R&D Cycle: High-precision testing minimizes iterations, accelerating engine certification.

6. Extended Recommendations

Digital Twin Integration: Test data can feed into blade digital twins for lifespan prediction.

Automated Testing: Robotic excitation and scanning laser vibrometry enhance efficiency.