Aero Engine Test Bed Upgrade Using DE-918 System

In August 2024, the 601 engine test bed was upgraded with DE-918 for precise multi-parameter monitoring and reliable engine verification.

Engine Rotor Modal Test Case Using DE-924U System

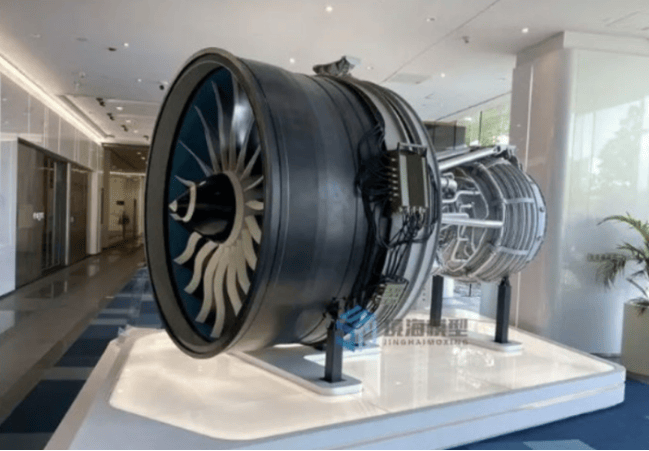

In July 2024, a modal test of an engine rotor was conducted using the DE-924U system. Fourteen measurement points captured vibration responses to identify natural frequencies, damping ratios, and mode shapes, validating rotor design and mitigating resonance and fatigue risks.

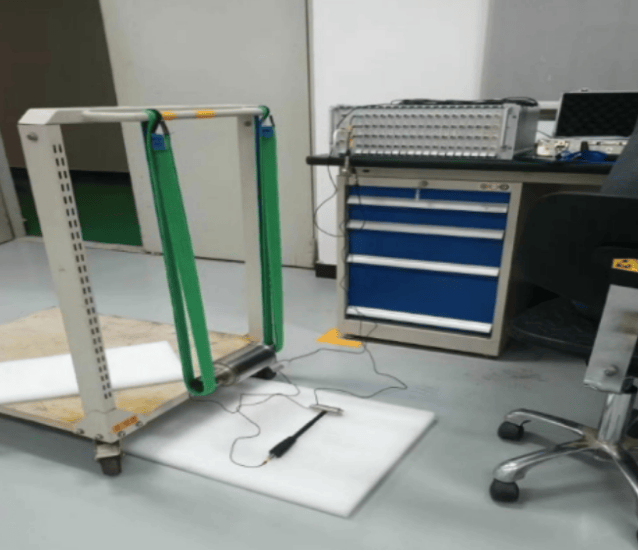

Rudder Actuator Surface Modal Test Case with DE-928U System

In June 2024, a modal test of a rudder actuator surface was conducted using the DE-928U system. Multi-input excitation and high-speed synchronous acquisition captured natural frequencies, damping ratios, and mode shapes, validating structural models and mitigating resonance risks for flight safety.

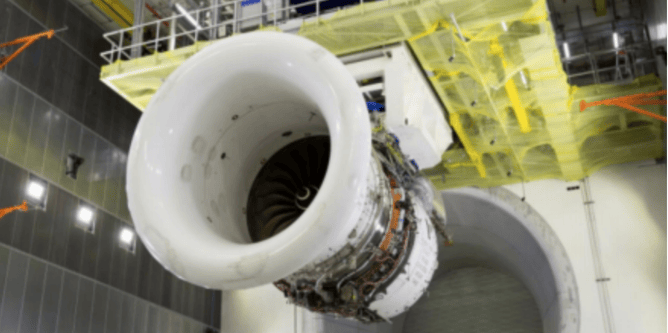

Aero Engine Turbine Research Institute Engine Pulsation Test

In June 2024, the Aero Engine Turbine Research Institute conducted pulsation testing on an aircraft engine using the DE-928U system. Multi-dimensional vibration, pressure, and speed data validated engine reliability, identified excitation sources, and ensured compliance with military performance standards.

Customized DE-944 Dynamic Signal Test and Analysis System

In June 2024, an engine research institute performed ignition tests on a specific engine model to analyze its dynamic behavior under startup conditions. Using the customized DE-944 Dynamic Signal Test and Analysis System, the project measured pulsating pressure, vibration acceleration, and rotational speed, delivering critical insights for engine design optimization and operational reliability.

Multi-Parameter Engine Testing & Monitoring Solution

How an aviation institute achieved precise, real-time multi-parameter testing and monitoring for Il-76 aircraft engines using Dynatronic’s advanced acquisition system.

Next-Gen Spaceship Landing and Water Impact Test

How engineers validated the new manned spaceship’s recovery capsule with advanced sensors and rugged data acquisition systems during landing and water impact tests.

High-Precision Airdrop Landing Impact Test with DE-928U

A military research institute adopted the DEWEsoft DE-928U system to accurately simulate and analyze the extreme landing impacts experienced by airdropped supplies.

Precision Equipment Vibration Damping Test Results

In March 2024, a research institute conducted vibration damping tests for precision equipment using RE-846U, demonstrating significant attenuation, resonance suppression, and engineering applicability for high-precision device transport.

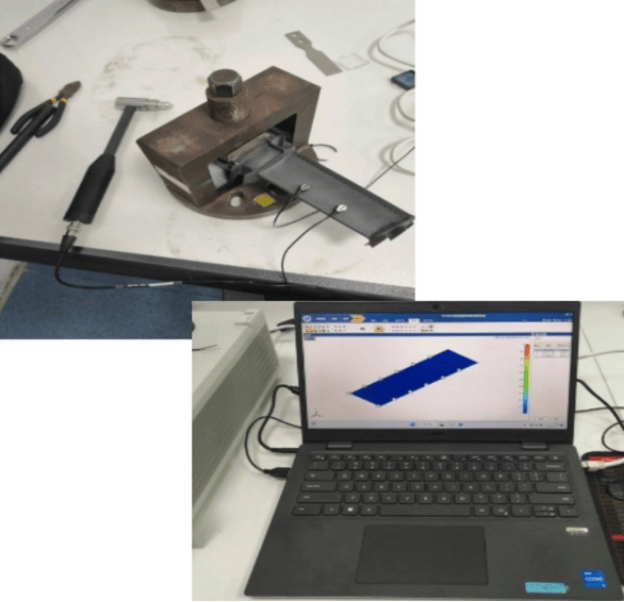

Engine Blade Modal Testing with DE-924U System

In March 2024, an airline conducted engine blade modal testing with DE-924U, analyzing natural frequencies, mode shapes, and resonance risks. Results support fatigue life prediction, predictive maintenance, and next-generation turbine blade design validation.

Flight Load Testing of the AG600 Amphibious Aircraft

Flight load testing of the AG600 aircraft evaluated structural stability under water-takeoff, landing, and in-flight maneuvers. Data from 18 SE-98 systems and over 2,000 strain gauges validated design models and ensured compliance with safety standards.

Rocket Sled Track Mechanical Parameter Testing

Rocket sled track testing evaluated modal dynamics, impact shocks, and thermal-strain behavior. Data from RE-846U and RU-846 systems established design baselines for safety, performance, and next-generation material improvements.

Aircraft Full-Scale Static & Fatigue Structure Test System

The SE-98 system supports 16,000-channel full-scale structural testing at CASI, providing precise strain, displacement, load, and thermal measurements for both static and fatigue evaluations of aircraft airframes.

Aircraft Airbag Drop Impact Test for Shock Performance

Controlled drop tests were performed to evaluate the shock absorption performance of aircraft landing gear airbags using a multi-channel dynamic measurement system.

High-Temperature Sensor Comparative Test for Aeroengines

A comparative test validated the performance of domestic TD1A627 high-temperature accelerometers against imported sensors, confirming accuracy, stability, and reliability for aeroengine applications.

Aircraft Fuselage Load Testing for Structural Integrity

Comprehensive fuselage load testing validated structural integrity, identified stress-critical areas, and confirmed FEA models using SE-864U systems and advanced strain/displacement measurement.

Aeroengine Performance Testing for Next-Gen Engines

Comprehensive aeroengine testing in March 2024 measured vibration, thermal, deformation, and angular characteristics across all operating conditions, supporting next-gen engine development.

Underwater Aircraft Strain Testing at Harbin Lab

Peking University conducted underwater strain testing on an aircraft at Harbin Engineering University using the RE-846U system with triaxial rosettes. Measurements under 0.4–2.4 m/s flow assessed bending, torsion, and hydrodynamic stress, validating CFD and FEA models. The results supported design optimization, material selection, and structural integrity assessment for underwater operations.

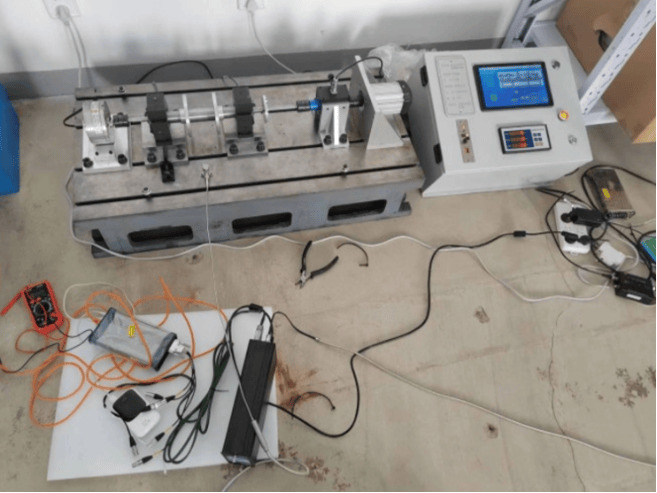

Comprehensive Turbine Rig Performance Testing

Dynatronic’s 32-channel DE-924U system was used for comprehensive turbine rig testing in Shanghai. Vibration and speed signals were synchronized to identify excessive vibration causes, including imbalance, gear meshing, bearing defects, and structural resonance. Post-correction improvements achieved 30–50% vibration reduction, supporting design optimization, fault prevention, and efficient multi-point testing.

Wind Turbine Blade Modal Testing Solution

Dynatronic’s wind turbine blade modal testing solution provides low-frequency, high-precision measurement of natural frequencies and damping using optimized accelerometers and SE-884U DAQ systems. Supports force and ambient excitation methods, mass effect compensation, and integrated modal analysis for blade health monitoring, FEM validation, and aeroelastic stability studies.