Customized DE-944 Dynamic Signal Test and Analysis System

I. Project Background and Objectives

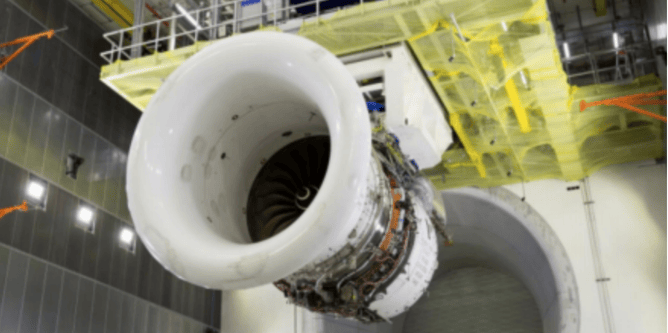

In June 2024, an engine research institute conducted ignition tests on a specific engine model to evaluate its mechanical performance during startup. The objective was to analyze the engine's dynamic behavior under ignition conditions, including pulsating pressure, vibration acceleration, and rotational speed. These data are critical for optimizing engine design, ensuring structural integrity, and enhancing operational reliability.

II. Solution: Customized DE-944 Dynamic Signal Test and Analysis System

The project employed a customized DE-944 Dynamic Signal Test and Analysis System to synchronously acquire and analyze multi-parameter data during ignition.

System Configuration:

1. Sensors Deployed:

Pressure Sensors: Installed in the combustion chamber and fuel injection system to capture pulsating pressure fluctuations during ignition.

Acceleration Sensors: Mounted on critical components (e.g., casing, mounts) to measure vibration acceleration in multiple directions.

Eddy Current Sensors: Used to monitor rotational speed and displacement of rotating parts (e.g., turbine blades).

2. Data Acquisition Hardware:

The DE-944 system supported high-speed synchronous acquisition of all sensor channels, with a sampling rate of up to 256 kS/s and 24-bit resolution.

Customized signal conditioning modules ensured compatibility with pressure, acceleration, and eddy current sensors.

3. Software and Analysis Tools:

Real-time data display and analysis software provided instant visualization of time- domain and frequency-domain parameters.

Advanced algorithms enabled automatic extraction of key metrics such as peak pressure, vibration spectra, and rotational speed trends.

III. Testing Process and Data Insights

3.1 Test Execution

The engine was ignited under controlled conditions while the DE-944 system simultaneously acquired data from all sensors.

Multiple ignition cycles were conducted to ensure data repeatability and statistical significance.

3.2 Key Findings

Pulsating Pressure Analysis:

Pressure fluctuations during ignition exhibited a peak value of ±0.8 MPa, with dominant frequencies below 500 Hz.

No abnormal pressure oscillations were observed, confirming stable combustion dynamics.

Vibration Acceleration Analysis:

Vibration levels were highest during the initial ignition phase (≤15 g), gradually stabilizing within 2 seconds.

Spectral analysis identified characteristic frequencies linked to fuel injection and combustion cycles.

Rotational Speed Monitoring:

Eddy current sensors captured precise speed profiles, showing a smooth acceleration to idle speed within 1.5 seconds.

No torsional resonances or overspeed events were detected.

3.3 Engineering Value

The data validated the engine’s structural robustness during ignition, with no excessive vibrations or pressure spikes.

Insights into transient behavior helped refine the ignition sequence, reducing mechanical stress on components.

The test demonstrated the engine’s compliance with design specifications and safety margins.

IV. Advantages of the DE-944 System

1. High Integration:

The customized system seamlessly integrated diverse sensors, simplifying setup and minimizing cabling complexity.

2. High Precision and Synchronization:

All channels were synchronized with microsecond-level accuracy, ensuring precise correlation between pressure, vibration, and speed data.

3. Ruggedized Design:

The hardware operated reliably in high-temperature and high-vibration environments, typical of engine test beds.

V. Application Prospects

This solution is applicable to a wide range of scenarios:

Aeroengine and Gas Turbine Ignition Testing;

Rocket Engine Transient Performance Validation;

Industrial Combustion System Optimization.