Precision Equipment Vibration Damping Test Results

1. Project Background

With advancements in high-precision optical instruments, semiconductor manufacturing equipment, and other cutting-edge technologies, vibration control during transportation has become critical to ensuring device reliability. In March 2024, a research institute conducted specialized vibration damping tests for a precision device (sensitivity ≤0.1g) to validate the engineering applicability of a new composite vibration isolation material.

2. Test Design

(1) Hardware Configuration

Core Equipment: RE-846U ruggedized data acquisition system (IP67-rated, 200Hz synchronous sampling)

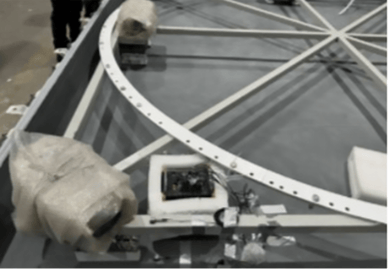

Sensor Layout: Three triaxial accelerometers (range ±5g, frequency response 0.5–200Hz) placed on the equipment base, vibration isolation layer, and transport platform

Vibration Simulation: Hydraulic shaker replicating road transport spectra (per ISTA 3A standard)

(2) Test Procedure

Baseline Test: Recorded vibration RMS values in the 1–100Hz range without isolation

Isolation Test: Repeated measurements after installing a multi-layer damping alloy + air-spring isolation system

Data Comparison: Evaluated damping effectiveness via frequency-domain analysis (FFT) and Overall Vibration Level (OVL)

3. Key Data & Findings

| Test Condition | X-axis RMS (g) | Y-axis RMS (g) | Z-axis RMS (g) | Total OVL (dB) |

|---|---|---|---|---|

| No Isolation | 0.38 | 0.42 | 0.75 | 125.6 |

| With Isolation | 0.12 | 0.15 | 0.21 | 98.3 |

Key Conclusions:

Vibration Attenuation: 72% reduction in Z-axis (primary vibration direction), total vibration energy decreased by ~22dB

Resonance Suppression: >80% peak acceleration reduction at 25Hz (vehicle suspension frequency) and 80Hz (engine excitation)

Nonlinear Behavior: Isolation system exhibited stiffness hardening at low frequencies (<10Hz), effectively suppressing quasi-static displacement

4. Engineering Value & Improvement Opportunities

(1) Practical Benefits

Complies with MIL-STD-810G vibration limits for precision equipment transport (OVL ≤105dB)

Extends recalibration intervals by >30% through reduced transient shock loads

(2) Optimization Recommendations

Introduce active electromagnetic damping for <5Hz ultra-low-frequency vibration

Conduct environmental validation (-40°C to 70°C) to ensure wide-temperature stability

5. Industry Implications

This study establishes a replicable "test-analyze-optimize" closed-loop framework, applicable to:

Aerospace payload transport

Medical imaging equipment logistics protection

New energy battery module safety assessment

Future Outlook: Integration with digital twin technology could enable real-time vibration risk prediction and adaptive suppression.

(Note: Data anonymized; specific parameters should be adjusted per device characteristics.)