Aircraft Fuselage Load Testing for Structural Integrity

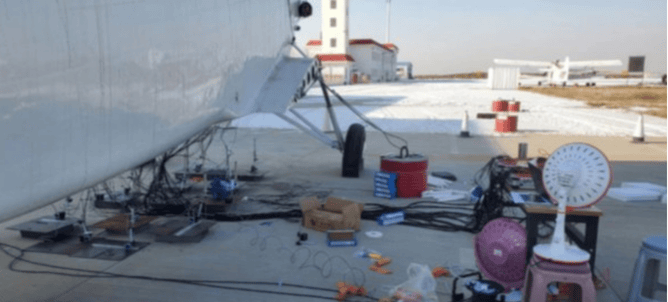

January 2024 - A university research team conducted comprehensive load testing on an aircraft fuselage structure using advanced measurement systems to evaluate structural performance under various loading conditions.

Test System Configuration:

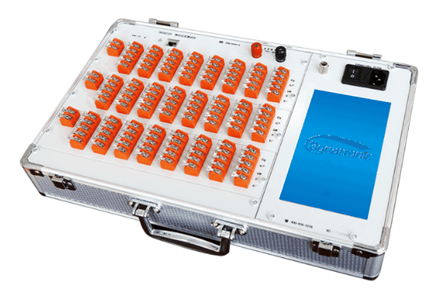

Primary equipment: 2 × SE-864U Static Stress-strain Testing and Analysis Systems

Measurement devices:

Strain gauges (multiple types) installed at critical locations throughout the internal cabin framework

Displacement transducers (LVDTs or similar) positioned beneath key sections of the fuselage

Load application system for controlled loading scenarios

Test Methodology:

1. Instrumentation Layout:

Strain gauges arranged in strategic patterns to capture:

Longitudinal and circumferential stresses

Bending and torsional deformation

Stress concentrations at structural joints

Displacement measurement points selected to monitor:

Overall fuselage deflection

Local deformation at load introduction points

2. Loading Protocol:

Applied incremental static loads representing:

Normal operational conditions

Design limit loads

Ultimate load cases (if applicable)

Multiple loading configurations to simulate:

Symmetrical and asymmetrical load distributions

Critical load paths

3. Data Acquisition:

Synchronized collection of strain and displacement data

Continuous monitoring during load application and removal

Multiple measurement cycles for repeatability verification

Data Analysis:

Processed strain data to determine:

Principal stress directions and magnitudes

Load transfer paths through the structure

Comparison with theoretical predictions

Displacement measurements used to:

Construct deflection profiles

Calculate structural stiffness characteristics

Identify any nonlinear behavior

Key Outcomes:

Structural performance validation under design loads

Identification of critical stress areas requiring potential reinforcement

Experimental verification of finite element analysis models

Database of strain/stress distributions for future reference

Technical Advantages:

The SE-864U system provided:

High-accuracy static strain measurement capability

Excellent long-term stability for extended tests

Synchronized multi-channel data acquisition

Comprehensive measurement approach enabled:

Full-field structural response characterization

Detailed load path analysis

Validation of structural modeling assumptions

Applications:

Aircraft structural certification support

Design optimization for weight reduction

Maintenance and repair evaluation

Educational demonstration of aircraft structural behavior

This test series provided critical experimental data supporting both academic research and practical aircraft development objectives. The methodology demonstrates a robust approach to full-scale aircraft structural testing using advanced but cost-effective measurement techniques.