Engine Blade Modal Testing with DE-924U System

Test Overview

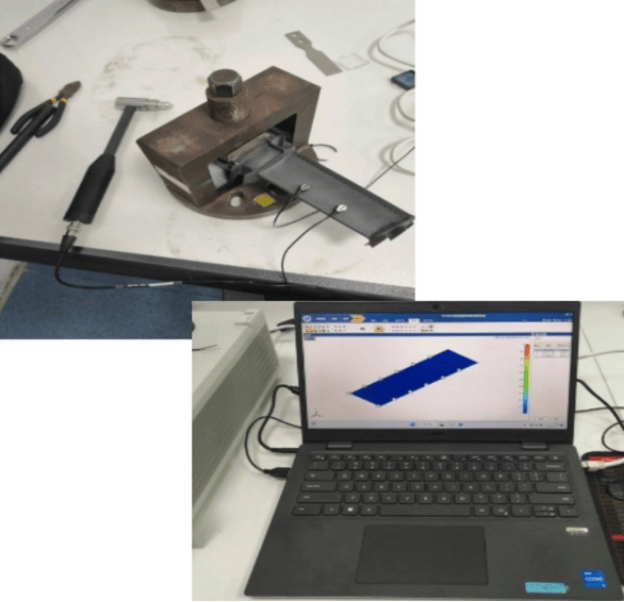

In March 2024, an airline conducted detailed modal testing of engine blades using the DE-924U Dynamic Signal Test and Analysis System. The goal was to evaluate the structural dynamic characteristics of the blades, identify potential resonance issues, and support fatigue life prediction for enhanced operational safety and performance optimization.

Test Setup & Methodology

Measurement Points: Six strategically selected locations along the blade to capture representative vibrational responses.

Excitation Method: Controlled impact excitation using a precision force hammer.

Sensor Configuration:

Two miniature accelerometers used in a batch measurement approach.

Signals captured synchronously at each measurement point.

Test Methodology: Force-based modal analysis conducted to determine:

Natural frequencies of the blades

Detailed mode shapes

Damping ratios where applicable

Key Objectives

Resonance Risk Assessment:

Detect whether blade natural frequencies align with engine rotational harmonics or other external excitation sources.

Prevent resonance-induced failures during operation.

Lifespan Evaluation Support:

Provide accurate dynamic response data for fatigue life prediction.

Aid in structural integrity assessment of rotating components.

Applications & Significance

Prevents vibration-related failures in high-speed turbine blades.

Supports predictive maintenance strategies by detecting early signs of structural wear.

Essential for next-generation turbine blade design validation, ensuring durability under operational conditions.

Offers insight into vibration behavior for operational optimization and efficiency improvement.

Technical Insights

High-precision accelerometers and DE-924U system provide high-resolution measurement of dynamic responses.

Batch measurement approach allows for efficient and repeatable testing across multiple blades.

Force-based modal testing provides robust identification of mode shapes and natural frequencies critical for design verification.

Conclusion

The engine blade modal testing campaign successfully characterized the dynamic behavior of the blades, identifying natural frequencies, mode shapes, and resonance risks. By combining DE-924U high-precision measurements with force-based modal analysis, the study ensures operational safety, supports predictive maintenance, and provides critical data for fatigue life evaluation. These insights not only optimize current engine performance but also guide the design of next-generation turbine blades for long-term reliability and efficiency.