High-Temperature Sensor Comparative Test for Aeroengines

Project: High-Temperature Sensor Comparative Test for Aeroengines

April 2024 · Aeroengine Research Institute

An aerospace research institute planned to replace foreign high-temperature accelerometers used in engine high-temperature tests with domestic TD1A627 high-temperature accelerometers, using Dynatronic charge amplifiers for signal conditioning. To ensure the domestic sensors met performance requirements, a comparative test was conducted to verify measurement accuracy, high-temperature stability, and vibration response characteristics.

Test Plan

1. Test Equipment

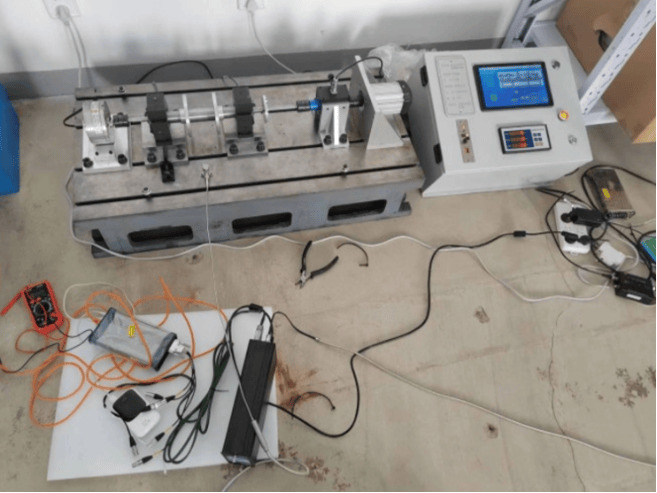

Vibration Excitation Equipment:

Electrodynamic shaker (room-temperature comparison)

Engine high-temperature test rig (high-temperature validation)

Test Sensors:

Domestic Sensor: TD1A627 high-temperature accelerometer (max. 650°C)

Imported Sensor: Original foreign high-temperature accelerometer (benchmark)

Data Acquisition System:

Dynatronic high-precision charge amplifier (low noise, wide bandwidth)

Dynamic signal analyzer (frequency response analysis)

2. Test Procedure

1. Room-Temperature Vibration Comparison (Lab Conditions)

Mounted domestic and imported sensors side by side on the shaker.

Applied 5–2000 Hz sweep vibration to compare amplitude linearity and phase coherence.

Conducted random vibration and shock tests to validate dynamic response consistency.

2. High-Temperature Performance (Engine Test Rig)

Installed both sensors synchronously near the combustion zone.

Gradually heated to 650°C, monitoring output stability.

Applied operational-band vibrations under high temperature, analyzing SNR and drift.

Test Results

1. Room-Temperature Comparison

| Parameter | Domestic TD1A627 | Imported Sensor | Deviation |

|---|---|---|---|

| Sensitivity (mV/g) | 10.2 | 10.5 | ±2.9% |

| Freq. Response (5–2kHz) | ±5% | ±4% | ≤1% |

| Phase Coherence (1kHz) | 2° | 1.5° | 0.5° |

Conclusion: At room temperature, the domestic sensor matched the imported one, meeting vibration measurement requirements.

2. High-Temperature Test

Thermal Stability:

At 650°C, the domestic sensor showed <3% sensitivity drift (imported: <2%).

Signal Quality:

SNR >50 dB, comparable to the imported sensor.

Structural Reliability:

No insulation degradation or mechanical loosening observed.

Conclusion: The domestic sensor performed reliably under high-temperature conditions, proving viable for replacement.

Engineering Value

Cost Reduction: Domestic sensors cut procurement costs by >40%.

Supply Chain Security: Reduces reliance on foreign high-temperature sensor technology.

Scalability: The methodology applies to other high-temperature vibration monitoring (e.g., gas turbines, rocket engines).

The domestic TD1A627 sensor demonstrated comparable accuracy and stability to imported sensors, proving it a reliable and cost-effective alternative for high-temperature aeroengine testing.