Multi-Channel Laser Vibrometer for Modal Testing

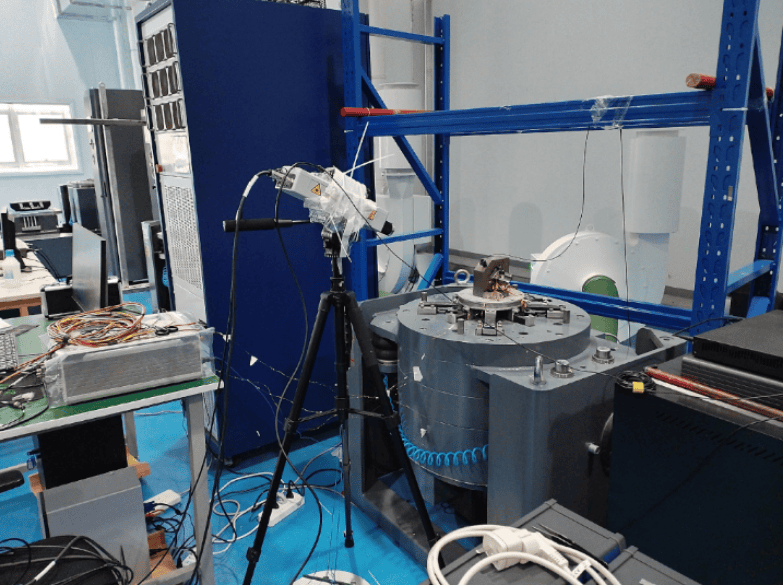

A national aerospace institute used Dynatronic’s VibroMicro VM-S-100 Multi-Channel Laser Doppler Vibrometer to perform modal testing of high-temperature materials. The system delivered precise, non-contact vibration measurements across multiple points, revealing natural frequencies, damping ratios, and mode shapes vital for aerospace material research and design optimization.

ODS Analysis of Aero Thin-Walled Panel Structure

Dynatronic’s VibroMicro Laser Doppler Vibrometers were used to analyze the operational deflection shapes of thin-walled aero panels under high-temperature acoustic excitation. The test visualized vibration modes, identified fatigue-prone areas, and provided crucial data for improving structural design and ensuring reliability in extreme environments.

Innovative Use of VibroMicro in Aero-Engine Testing

A national aerospace institute employed Dynatronic’s VibroMicro Laser Doppler Vibrometer and DE-944 data system to measure aero-engine blade vibrations at 800°C. This high-temperature, non-contact testing validated VibroMicro’s precision, stability, and cost-effectiveness—establishing it as the chosen solution for advanced aero-engine research.

Laser Doppler Vibrometers Applications in Aircraft Research

Laser Doppler Vibrometers (LDVs) have become essential in modern aircraft research. With non-contact precision and full-field vibration mapping, they enable aeroelastic testing, modal analysis, and structural diagnostics—advancing aircraft safety, performance, and noise control from component development to full-scale flight validation.

Wireless Modal Testing of Spacecraft Recovery Tower

Using 8 WW-826D systems, Dynatronic conducted wireless modal testing on a 140m spacecraft recovery tower, validating design accuracy under ambient excitation.

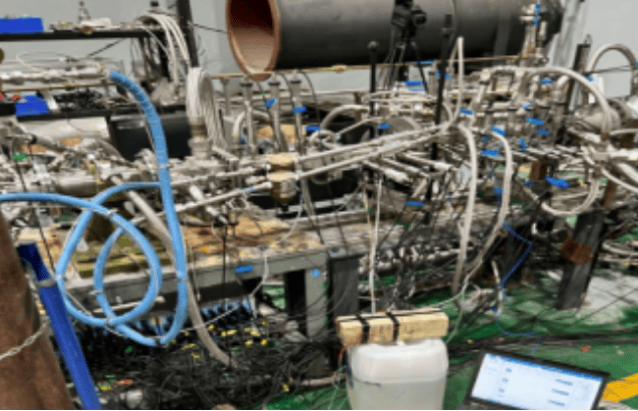

Case Study Report: RE-846U Aero-Engine Surge Test

Dynatronic’s RE-846U system captured vibration data during an aero-engine surge test at an aviation university, supporting safety research and stability design.

Vibration and Strain Testing for Aero-Engine Components

Dynatronic’s 64-channel hybrid system combined DE-924U and DE-928U models for precise vibration and strain testing of aero-engine components under dynamic loads.

Fan Blade Out (FBO) Test of A Commercial Aero-Engine

Dynatronic’s in-vacuum wireless telemetry system measured propeller strain during a Fan Blade Out test, delivering real-time data for safety certification.

Hydrostatic Pressure Test of Aero-Engine Casing

Dynatronic’s hydrostatic pressure test of an aero-engine casing measured strain and displacement under 25 MPa, ensuring strength, safety, and certification readiness.

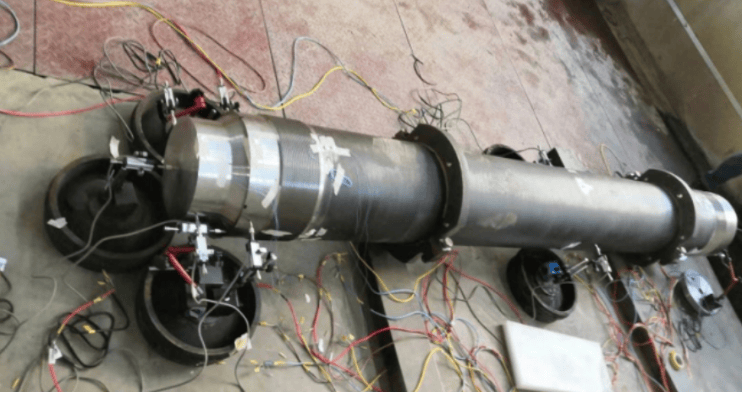

Case Analysis Report: Engine Strain and Torque Testing

Dynatronic applied wireless telemetry to measure strain and torque on a rotating aero-engine shaft, solving signal transfer challenges and ensuring data accuracy.

Strength Testing of New Cladding Material for Aero-Engines

Dynatronic’s strength test of a new aero-engine cladding material delivered compressive performance data with high-precision sensors and isolated acquisition systems.

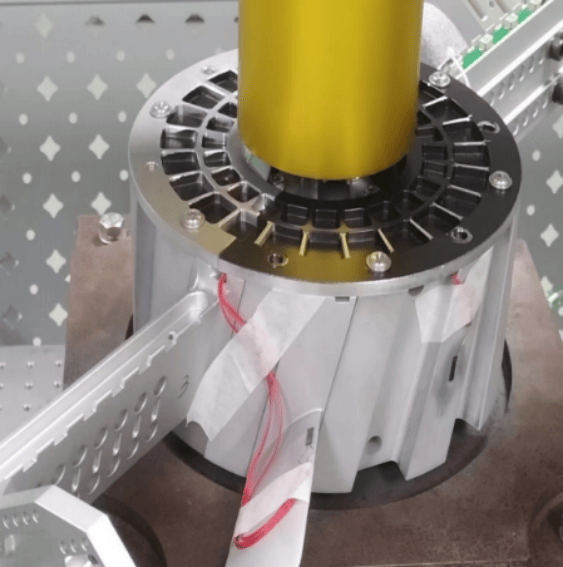

Aero-Engine Turbine Shaft and Blade Stress Experiment

Dynatronic’s aero-engine stress experiment for turbine shafts and blades synchronized 133+ channels, capturing high-speed bird strike and thermal response data.

6000-Channel Integrated Test Platform for a New Aircraft

Dynatronic’s 6000-channel test system for a major airline enables integrated aircraft validation, combining scalability, interoperability, and custom software modules.

Winning the Bid for CATRI's 16,000-Channel Testing System

Dynatronic’s successful bid for CATRI’s 16,000-channel strain testing system marks a breakthrough in large-scale aircraft structural testing solutions.

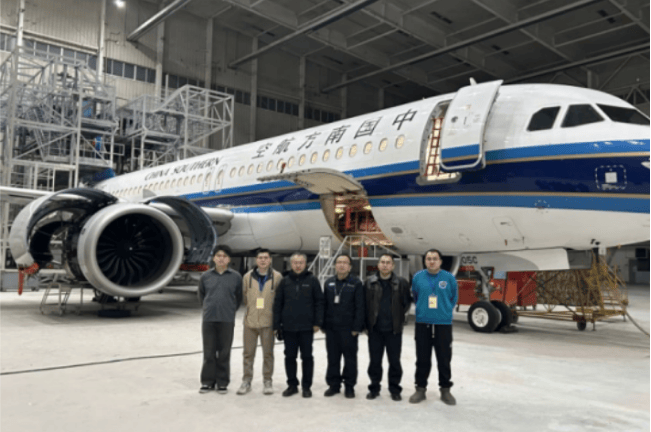

Fuselage Strain Testing on Large Passenger Jet

In December 2024, DUT partnered with a major airline to measure fuselage strain and deformation during a complete flight cycle. Using the RU-846 Rugged Data Recorder, the test captured real-world stress data at 32 critical points to validate design safety and structural integrity.

2024 Rocket Launch Environment Effects Testing

Discover how a wireless dynamic strain test system enabled accurate data collection during extreme rocket launch conditions in 2024.

New Generation Manned Spaceship Landing & Water Impact Test

In May 2024, engineers conducted landing and water impact tests on a new-generation manned spaceship to capture detailed strain and vibration data for mission safety.

Engine Vibration Monitoring Using DE-944 System

Multi-point engine vibration test captures triaxial acceleration data to support structural optimization and fault detection using DE-944.

Pressure Vessel Strain Test Using RE-Series DAQ

Pipeline pressurization test captures multi-directional strain data to validate design and safety using RE-Series DAQ.

Spacecraft Drop Simulation Test Using RE-Series DAQ

High-altitude drop test validates spacecraft recovery system with RE-Series data acquisition.