Innovative Use of VibroMicro in Aero-Engine Testing

Abstract: This case study details how a national-level aerospace research institute successfully employed Dynatronic VibroMicro Laser Doppler Vibrometer (equipped with the DR-L-F28 lens) alongside a DE-944 dynamic data acquisition system to characterize the high-frequency, micro-amplitude vibrations of engine blades under extreme conditions of 800°C. The report elaborates on how this solution overcame severe challenges related to high temperature and pressure. Through a comparative analysis with a competing system, VibroMico was validated for its superior performance, design, and cost-effectiveness, leading to its selection as the designated equipment for this critical testing project.

1. Project Background & Testing Challenges

During the development of a new aero-engine, understanding the vibration characteristics of turbine blades under real operational conditions is paramount for ensuring reliability, longevity, and safety. When subjected to high-temperature, high-pressure gas flow, blades experience high-frequency modal vibrations with minimal displacement amplitude, which is a primary cause of high-cycle fatigue failure. Consequently, vibration testing under conditions that closely mimic real-world operation is an indispensable part of the R&D validation process.

The primary challenges faced in this project included:

Extreme Environment: Testing required simulating an environment of 800°C and high pressure, where traditional contact sensors (e.g., strain gauges) struggle to function reliably.

High-Frequency, Micro-Amplitude Measurement: Blade vibrations are characterized by high frequencies and minute displacements, demanding exceptional precision, resolution, and dynamic response from the measurement system.

Non-Contact Requirement: A non-contact method was essential to avoid mass-loading effects that alter blade dynamics and to protect the sensor from the harsh environment.

Data Integrity: Complete and synchronous recording of all dynamic data was necessary for in-depth modal analysis and fault diagnosis.

2. Testing Solution

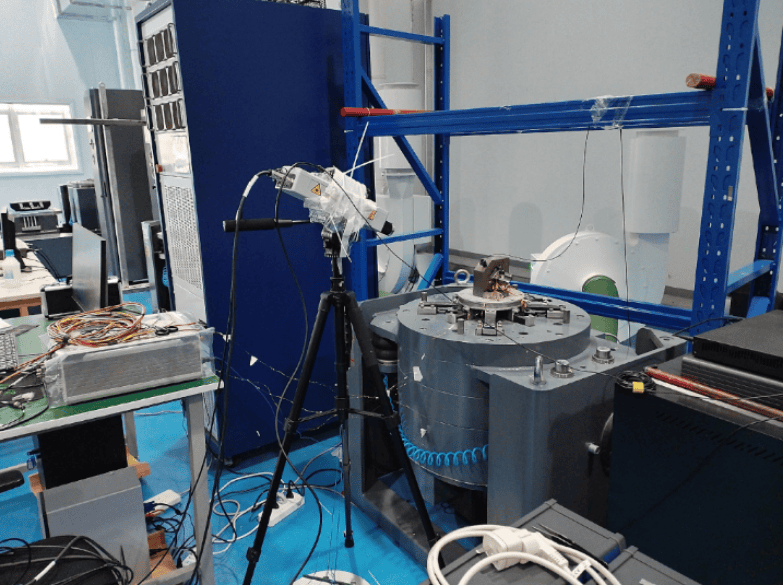

To address these challenges, the research institute implemented an advanced testing system centered on the VibroMico.

Core Vibration Measurement Equipment: Dynatronic VibroMicro Laser Doppler Vibrometer, specifically configured with the DR-L-F28 lens. It features a micro-sized design for easy integration into the limited space of the test rig. Its optics are optimized for high-temperature applications, ensuring stable capture of laser signals from the blade surface even against the 800°C background.

Data Acquisition System: A Dynatronic DE-944 high-precision dynamic data acquisition system was used. This system, with its high sampling rate, resolution, and multi-channel synchronous acquisition capability, guaranteed the distortion-free and complete recording of the high-frequency, weak vibration signals from the VibroMico, providing a reliable data foundation for post-processing.

Testing System Architecture Diagram

3. Test Procedure & Results

System Setup: The DR-L-F28 lens of the VibroMicro was precisely aligned with the test engine blade inside the high-temperature, high-pressure test chamber.

Condition Simulation: The test chamber was activated, gradually ramping up temperature and pressure to the target conditions (800°C and corresponding pressure).

Data Acquisition: With the blades subjected to aerodynamic excitation, the VibroMicro and DE-944 systems were activated to synchronously capture and record vibration data.

Comparative Validation: A competing laser vibrometer system was used for comparison testing under identical conditions.

Results:

The VibroMicro system performed stably throughout the test, successfully acquiring clear vibration signals from the blade at 800°C. It accurately identified high-frequency resonant frequencies and measured vibration displacements at micron and even nanoscale levels.

Compared to the competing system, VibroMicro demonstrated significant advantages in signal-to-noise ratio, measurement stability, and data consistency. Its data curves were smoother, and characteristic frequencies were identified more clearly, providing engineers with higher-confidence results.

4. Customer Evaluation & Decision Rationale

After rigorous comparative testing and technical evaluation, the research team highly endorsed the VibroMicro. The final decision was based on the following core advantages:

Exceptional High-Temperature Performance: The DR-L-F28 lens is maintaining superior measurement accuracy and reliability at the extreme temperature of 800°C, perfectly meeting the project's core requirement.

Superior Measurement Capability: For high-frequency and small-amplitude vibrations, the system demonstrates extremely high frequency resolution and displacement sensitivity, providing data that is far superior to the project requirements.

Miniaturization & Flexibility: The device's micro-sized design enabled easy integration into the space-constrained, complex test environment, significantly enhancing engineering implementation convenience.

Significant Cost-Effectiveness: While offering performance comparable to or even surpassing that of high-end competitors, the VibroMicro solution presented a distinct price advantage, delivering maximum value to the customer.

Based on these factors, VibroMicro was formally selected as the final designated equipment for vibration testing of this engine model's blades.

5. Conclusion

This application case solidly demonstrates the robust capability and technical leadership of the Dynatronic VibroMicro Laser Doppler Vibrometer in extreme environment testing for aero-engines.

It not only successfully solved the technical challenge of non-contact measurement of high-frequency, micro-amplitude vibrations under high temperature and pressure but also, with its miniaturized design and outstanding cost-effectiveness, provided a reliable, efficient, and economical perfect solution for R&D testing in the aerospace sector.

This successful collaboration has established a solid testing foundation for the research institute's subsequent engine development projects and highlights VibroMicro's core competitiveness in the high-end precision measurement market.