Wireless Modal Testing of Spacecraft Recovery Tower

In February 2023, at the Huailai Test Field in Hebei Province, the Institute of Aeronautical Engineering successfully conducted modal testing on a technologically complex and large-scale spacecraft recovery test tower. This tower is a critical ground facility for ensuring the safe recovery of spacecraft, and the accuracy of its dynamic characteristics is directly related to the success of the mission. This project aimed to validate the correctness of the tower's theoretical calculation model through field measurements, providing final experimental evidence for structural safety and reliability.

1. Testing Challenges

Extreme Structure: The tower platform is 140 meters high, with the highest point reaching 217 meters. This super-tall, flexible structure has low natural frequencies and dense modal patterns, making testing extremely challenging.

Numerous Measurement Points: To fully capture the dynamic characteristics of the structure, 120 measurement points were deployed. Traditional wired testing solutions would involve immense cabling workload, and the weight and pull of the cables could interfere with the results.

Excitation Difficulties: The massive scale of the tower structure made it impossible to use conventional shakers for effective excitation, necessitating a non-conventional testing method.

Complex Field Environment: The outdoor test site environment required a testing system with high reliability, strong anti-interference capability, and good portability.

2. Solution: Wireless Modal Testing Technology

To address these challenges, the project team opted for advanced Wireless Modal Testing Technology as the core solution.

Core Equipment: 8 sets of WW-826D Wireless Modal Test and Analysis Systems.

Wireless Advantage: Completely eliminated the burden of heavy cables, significantly reducing on-site deployment time and avoiding signal attenuation and noise issues associated with long cables.

Synchronization Accuracy: The systems feature high-precision clock synchronization, ensuring simultaneous data acquisition from all measurement points, which is essential for accurate modal parameter identification.

Flexible Expansion: The use of antenna extension cables effectively expanded the wireless network coverage, ensuring stable signal transmission across all parts of the 217-meter tower.

Testing Method: Output-Only Method (Ambient Excitation / Operational Modal Analysis - OMA).

This method only requires measuring the structural vibration response under natural environmental excitation (e.g., wind load, ground micro-vibrations), without needing to measure the input force or use excitation equipment.

It perfectly solved the challenge of effectively applying artificial excitation to super-large structures, enabling "non-destructive" and "non-intrusive" field testing.

Software Platform: The Dynatronic platform and its Modal Analysis Module were used for real-time data acquisition, storage, signal processing, and modal parameter identification (frequency, mode shapes, damping ratios).

System Configuration Diagram

[Tower Schematic]

|

|--- 120 wireless sensor measurement points evenly distributed

|

|--- Data transmission via wireless network

|

|--- Central Acquisition Station (Running Dynatronic Software)

|

|--- Result Analysis & Report Generation

3. Test Implementation and Results

Implementation Process:

Planning & Point Layout: Wireless sensors were deployed at 120 key locations based on the tower's structural mechanics.

System Deployment: The wireless acquisition network was quickly set up, and system debugging and synchronization checks were completed.

Data Acquisition: Long-duration, continuous data acquisition was performed under ambient excitation, obtaining high-quality structural response signals.

Data Analysis: The Dynatronic Modal Analysis Module was used to extract modal parameters.

Key Results:

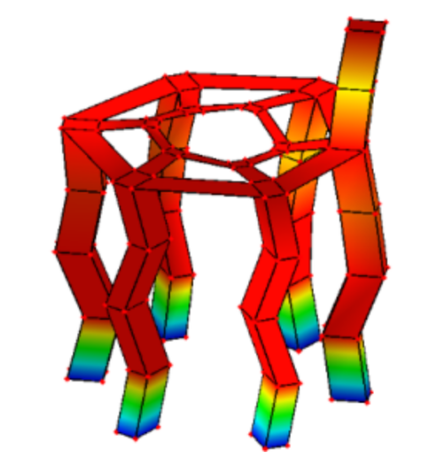

Successful Acquisition of Modal Parameters: Multiple dominant natural frequencies, mode shapes, and damping ratios of the tower were clearly identified.

Successful Model Validation: Comparison between the measured results and the client's theoretical calculation model showed they were largely consistent, strongly validating the accuracy of the design model.

Project Goals Achieved: The overall test data was complete and reliable, fully meeting the client's requirements for structural dynamic characteristic verification.

4. Conclusion and Value

This case successfully addressed several world-class challenges in modal testing of super-large aerospace facilities, fully demonstrating:

The Excellent Performance of the WW-826D Wireless Modal Testing System: Its stability, convenience, and high precision in large-scale, complex field environments were exceptionally demonstrated, making it an ideal replacement for traditional wired testing.

The Practical Value of the Output-Only Method (OMA): It provides an efficient and economical standard method for dynamic testing of structures like large civil engineering projects and aerospace facilities where artificial excitation is impractical.

Capability to Support Major Projects: This project not only provided critical data support for the safe operation of the spacecraft recovery tower but also accumulated valuable practical experience for dynamic testing of similar super-large structures, signifying that China's testing technology in this field has reached advanced international levels.