Engine Vibration Monitoring Using DE-944 System

I. Project Background and Objectives

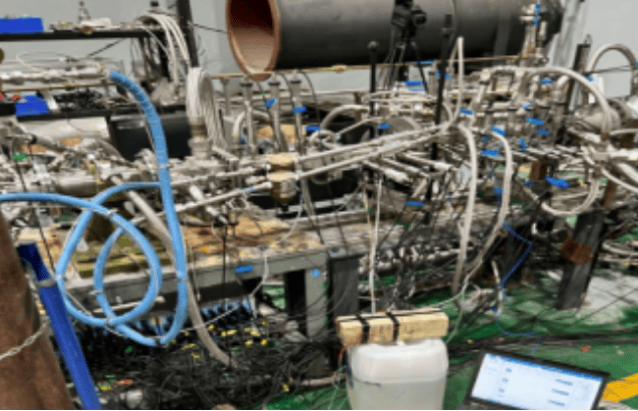

In October 2024, a Northwestern polytechnic university conducted a vibration test on an engine using the DE-944 Dynamic Signal Test and Analysis System. The test aimed to monitor triaxial vibration acceleration at key front, middle, and rear sections of the engine during operation, evaluating vibration magnitude, frequency distribution, and stability. The data supported engine structural optimization and fault diagnosis.

II. Test System and Solution Design

1. Sensor Arrangement

Sensor Type: 3 triaxial ICP accelerometers;

Locations:

Front Section: Compressor casing (monitoring rotor unbalance excitation);

Middle Section: Combustion chamber housing (capturing gas pressure pulsation response);

Rear Section: Turbine outlet casing (assessing turbine dynamic balance).

Orientation: Each sensor measured X (axial), Y (radial), and Z (tangential) vibrations.

2. Data Acquisition System

Core Equipment: DE-944 system supported 9-channel synchronous acquisition (3 sensors × 3 directions);

Sampling Rate: 10 kS/s (covering 0-5 kHz frequency range);

Anti-Aliasing Filter: Built-in digital filter with 5 kHz cutoff frequency.

3. Test Conditions

Engine operating ranges: Idle, cruise, maximum continuous thrust (MCT);

Each condition was sampled for 2 minutes to ensure statistical stability.

III. Test Results and Data Analysis

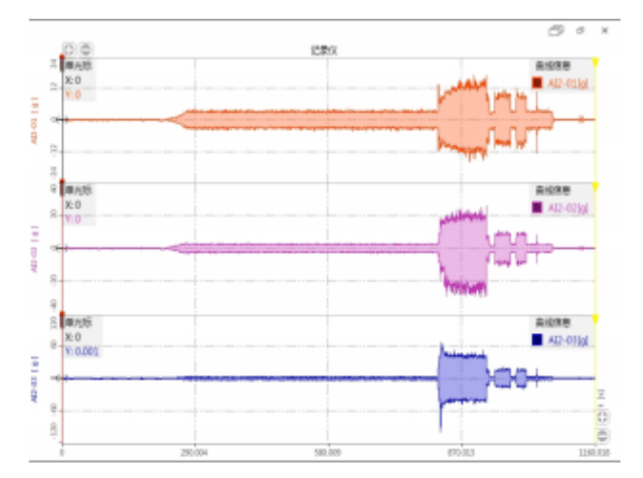

1. Vibration Magnitude Comparison

Idle Condition:

Front section dominated by radial vibration (peak 1.8 g), main frequency = rotor 1× order;

Middle section showed significant axial vibration (1.2 g), correlated with combustion pressure pulsation.

Cruise Condition:

Rear section tangential vibration increased to 2.5 g (turbine blade passing frequency excitation);

Total vibration at all sections <4.0 g, complying with GJB 4057-2000 limits.

Maximum Continuous Thrust:

Front vibration slightly increased (2.2 g) with pure spectrum, no non-synchronous vibration;

Middle section exhibited 20-200 Hz broadband vibration (combustion noise contribution).

2. Stability Assessment

Vibration standard deviation <0.15 g under all conditions, indicating stable operation;

Axial vibration transient changes <10% during condition transitions, no abnormal shocks.

3. Fault Early Warning Value

Weak harmonics detected at 2.5 kHz in rear tangential vibration (suspected early bearing damage);

Recommended lubrication improvement and continuous monitoring to prevent fault progression.

IV. Core Advantages of the DE-944 System

High Synchronization Precision

<0.1° phase error across 9 channels, ensuring accurate triaxial vibration phase relationships.

Real-Time Processing Capability

Built-in FFT and order analysis functions enabled real-time spectrum and order slice display during testing.

Engineering Design

TEDS sensor auto-recognition allowed system configuration within 5 minutes;

Exported data compatible with MATLAB/LMS Test.Lab analysis platforms.

V. Customer Benefits

Teaching and Research Value: Provided students with practical engine vibration testing cases, strengthening theory-practice integration;

Structural Optimization Basis: Identified vibration weak points to guide reinforcement design;

Predictive Maintenance: Established vibration baselines for engine health management research.

VI. Application Expansion

This solution applies to:

Vibration monitoring of aero-engines and gas turbines;

NVH testing of vehicle powertrains;

Fault diagnosis of industrial rotating machinery.