Fuselage Strain Testing on Large Passenger Jet

1. Project Overview

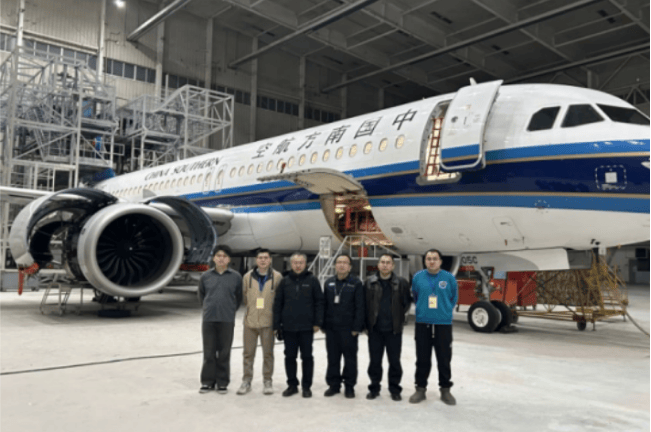

In December 2024, Dalian University of Technology (DUT) collaborated with a major Chinese airline to conduct a comprehensive airframe strain and strength test on a large passenger aircraft. The project utilized the RU-846 Rugged Data Recorder as the core data acquisition system.

2. Test Objective

The primary goal was to measure the structural strain and deformation experienced by the aircraft fuselage during a complete, representative flight cycle (e.g., taxi, take-off, climb, cruise, descent, landing, and braking).

3. Key Challenges

Real-world Testing: Capturing data during an actual flight or ground simulation under operational conditions.

Complex Stress Fields: Measuring strain in areas with complex geometry and load paths.

Data Integrity: Ensuring reliable, high-quality data acquisition throughout the entire duration of the flight cycle without external intervention.

Environment: Equipment needed to be robust enough for the aircraft environment without interfering with normal operations.

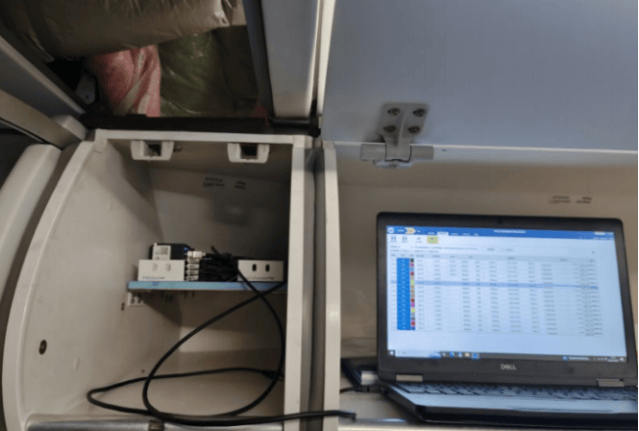

4. System Solution: RU-846 Rugged Data Recorder

The RU-846 system was chosen for its key capabilities:

Ruggedized Design: Built to withstand potential vibrations and environmental variations encountered during testing.

Offline (Standalone) Operation: Self-contained operation with internal power and storage was crucial for in-flight testing, eliminating the need for complex cabling or real-time transmission systems.

High Channel Count: Capable of handling the significant number of measurement points.

Precision: Suitable for high-accuracy strain measurements required for structural analysis.

5. Test Setup & Instrumentation

Sensor Type: Strain Rosettes (Strain Gauge Rosettes) were used at all locations to determine the complete state of surface strain (magnitude and direction) at each point.

Measurement Points: A total of 32 measurement points were strategically installed on critical areas of the airframe, including:

Fuselage Constant-section: To measure primary bending and hoop stresses.

Wing Sections: To capture loading and flexure of the main wings.

Major Component Joints/Connections: To assess stress concentrations and load transfer at critical interfaces (e.g., wing-fuselage attachment points).

Data Acquisition: The RU-846 recorders were configured for offline sampling, recording data from all strain rosettes continuously throughout the entire flight cycle.

6. Outcome

The test successfully captured the complete structural stress and deformation data across all 32 measurement points for the duration of a full flight cycle. The data provided invaluable insights into the actual load distribution and structural behavior of the aircraft under real operating conditions. This information is critical for validating computational models, ensuring airframe integrity, informing maintenance schedules, and supporting future design improvements.