Hydrostatic Pressure Test of Aero-Engine Casing

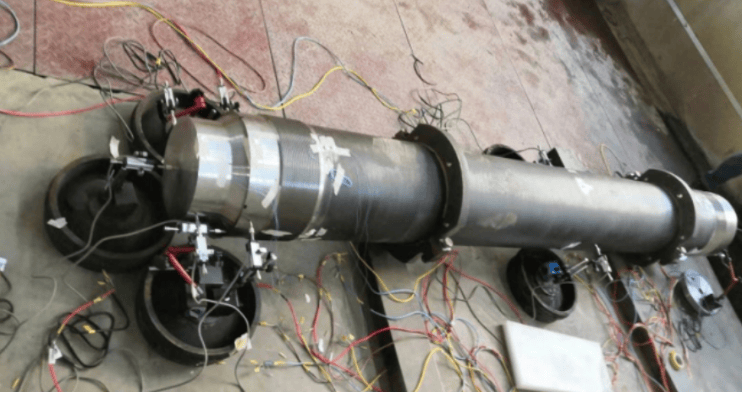

This case analyzes a hydrostatic pressure test conducted in October 2022 for a research institute. The test was performed to validate the structural integrity and pressure-bearing capacity of an aero-engine casing, a critical safety component. By progressively increasing internal water pressure to 25 MPa while monitoring for leaks and measuring strain and displacement, the test provided essential data to verify that the casing met its stringent design requirements. The case demonstrates the application of a robust and precise data acquisition system for component qualification under extreme static loads.

1. Project Background & Overview

Client & Objective: A research institute needed to certify the pressure capability of a new aero-engine casing. The primary objective was to ensure the casing could withstand the extreme internal gas pressures generated during engine operation without failure or excessive deformation.

Safety Criticality: The engine casing must contain high-energy debris in a failure scenario, making its structural integrity a paramount safety requirement.

Testing Method: A hydrostatic pressure test was employed. The casing was filled with water and pressurized in stages from 2 MPa to 25 MPa using a pump. The test involved both a visual inspection for leaks and a quantitative measurement of structural deformation.

2. Core Solution & Technical Highlights

The solution focused on accurately measuring the casing's structural response to increasing internal pressure.

1. Dual-Parameter Deformation Measurement:

Strain Measurement (Multiple Channels): Multiple strain gauges were bonded to critical locations on the casing. These gauges provided high-sensitivity data on local micro-deformations, allowing engineers to identify stress concentrations and verify that material stresses remained within allowable limits throughout the pressure ramp.

Displacement Measurement (10 Channels): Ten 5G102 displacement sensors (likely LVDTs) were used to measure absolute deflection or bulging of the casing structure under pressure. This macro-level deformation data is crucial for validating overall structural stiffness and geometric stability.

2. Reliable and Centralized Data Acquisition:

System Configuration: A single DE-944 Dynamic Signal Test and Analysis System served as the central acquisition unit. It provided sufficient channels to accommodate all strain gauges and displacement sensors simultaneously.

Synchronized Data Capture: The system ensured that all strain and displacement measurements were perfectly synchronized with the applied pressure levels, which is critical for correlating structural response with load.

Unified Software Platform: The Dynatronic basic software platform provided a unified interface for real-time monitoring of all sensor data, configuration of acquisition parameters, and secure data storage for post-test analysis.

3. Analysis of Key Success Factors

High-Pressure Test Expertise: The solution effectively addressed the challenges of a high-pressure qualification test, where data accuracy and system reliability are non-negotiable.

Comprehensive Structural Insight: The combination of local strain and global displacement measurements provided a complete picture of the casing's structural behavior, enabling a thorough assessment of both strength and stiffness.

Proven System Reliability: The use of the rugged and precise DE-944 system ensured data integrity throughout the critical and potentially destructive test sequence, up to the maximum proof pressure.

4. Project Significance & Value

Value for the Client (Research Institute): The test delivered definitive pass/fail criteria and rich quantitative data:

Structural Validation: Confirmed the casing could withstand the required proof pressure without leakage or rupture.

Design Verification: Provided data to validate and potentially refine finite element models (FEM) used in the design phase.

Safety Assurance: Generated critical evidence supporting the component's airworthiness and certification.

Value for Our Company: This project serves as a classic example of our capability in structural strength validation testing. It demonstrates the suitability of our systems for safety-critical, high-stakes component testing, reinforcing trust among aerospace engineers.

5. Conclusion & Outlook

The successful hydrostatic test of the engine casing underscores the role of precise data acquisition in ensuring the safety and reliability of aerospace components. It highlights a key application where reliable data directly contributes to risk mitigation.

Looking forward, this case suggests strategic opportunities:

Target Component Qualification Testing: Promote this proven solution to other sectors involved in pressure vessel testing, such as energy (gas turbines), automotive (fuel tanks), and industrial machinery.

Develop Standard Validation Packages: Bundle hardware and software with application-specific configurations for pressure testing, creating a streamlined, off-the-shelf solution for quality assurance labs.

Emphasize Safety and Certification Support: Use this case to highlight how our systems provide the data integrity and traceability required for rigorous certification processes.