Case Analysis Report: Engine Strain and Torque Testing

This case analyzes a specialized wireless telemetry test conducted in August 2022 for an aero-engine company. The project aimed to evaluate the performance of a new engine by directly measuring strain and torque on its rotating main shaft. The successful application of a wireless data recording system solved the critical challenge of transmitting signals from a high-speed rotating component, providing accurate and reliable data for engine validation.

1. Project Background & Overview

Client & Objective: An aero-engine company needed to validate the performance of a new engine design. The key objective was to directly measure the strain and torque experienced by the rotating main shaft under operational conditions to ensure it met design specifications.

Core Challenge: Measuring signals on a rotating shaft presents a significant technical hurdle, as traditional wired solutions are impractical due to continuous rotation and high speeds.

Solution: A wireless telemetry system was deployed. The system captured signals directly on the shaft and transmitted them wirelessly to a stationary receiver, enabling real-time data acquisition and analysis.

2. Core Solution & Technical Highlights

The solution's innovation lay in its wireless approach, specifically designed for rotating component testing.

1. Wireless Telemetry Application:

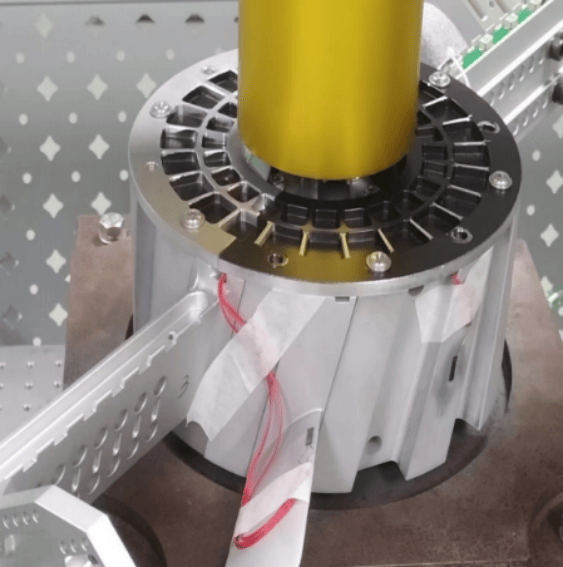

On-Shaft Instrumentation: Torque strain gauges were installed directly onto the main shaft in a specific configuration (typically a Wheatstone bridge) sensitive to torsional strain.

Wireless Data Transmission: Two WI-Series Wireless Data Recording Systems, along with their power modules, were mounted directly onto the rotating shaft. This setup captured the analog signals from the strain gauges, digitized them, and transmitted the data wirelessly to a stationary base station, eliminating the need for complex and unreliable slip rings or cables.

2. Integrated Data Processing & Software:

Real-Time Data Flow: The wirelessly received data was streamed to a computer, allowing for real-time display and storage of strain and torque signals during engine operation.

Specialized Software Analysis: The Dynatronic basic platform, enhanced with a dedicated Torque Calculation Module, was used. This module automatically converted the raw strain gauge bridge readings into accurate torque values using calibrated parameters, providing immediate engineering insight.

3. Analysis of Key Success Factors

Solving the Rotating Measurement Challenge: The wireless system provided a robust and elegant solution for acquiring high-quality data from the rotating shaft, which is the primary success factor of this test.

Data Integrity: Wireless transmission eliminated the noise and signal degradation often associated with slip rings, ensuring high data fidelity.

Operational Efficiency: The system simplified the test setup significantly compared to traditional wired or slip-ring methods, reducing installation time and complexity.

4. Project Significance & Value

Value for the Client (Engine Company): The test provided direct, accurate measurements of shaft torque, a critical parameter for validating engine power output, structural integrity of the shaft, and overall transmission system efficiency. This data is indispensable for final performance sign-off and certification support.

Value for Our Company: This project demonstrated our expertise in advanced rotational telemetry testing. It showcases our ability to provide solutions for one of the most challenging measurement scenarios in mechanical testing, strengthening our position in the high-end propulsion testing market.

5. Conclusion & Outlook

The successful execution of this wireless torque measurement test highlights our capability to address unique and demanding data acquisition requirements in aerospace propulsion.

Looking forward, this case provides a strategic outlook:

Promote Wireless Telemetry Solutions: Use this case as a flagship example to target clients in aerospace, automotive (powertrain testing), and heavy machinery sectors facing rotating measurement challenges.

Develop Application-Specific Kits: Consider creating pre-configured wireless torque measurement kits, including sensors, mounting solutions, and software modules, to simplify adoption for customers.

Highlight Niche Engineering Capability: Position this success as a key differentiator, emphasizing our deep understanding of both data acquisition and the specific challenges of rotating machinery dynamics.