Automotive Seat Vibration Testing with VM-S-100

This application case highlights how Dynatronic’s VM-S-100 Laser Doppler Vibrometer helped an automotive seat manufacturer identify the resonant frequency and vibration amplitude of a headrest bracket. The non-contact test delivered accurate, high-resolution NVH insights without altering the structure’s dynamic behavior.

Automotive Motor Shaft Runout Detection with VM-S-100

This case study presents how Dynatronic’s dual VibroMicro VM-S-100 Laser Doppler Vibrometer system enables real-time, non-contact shaft runout detection for automotive motors. With ±2μm repeatability, high-speed integration, and SPC capability, it delivers precise, automated quality control in demanding industrial environments.

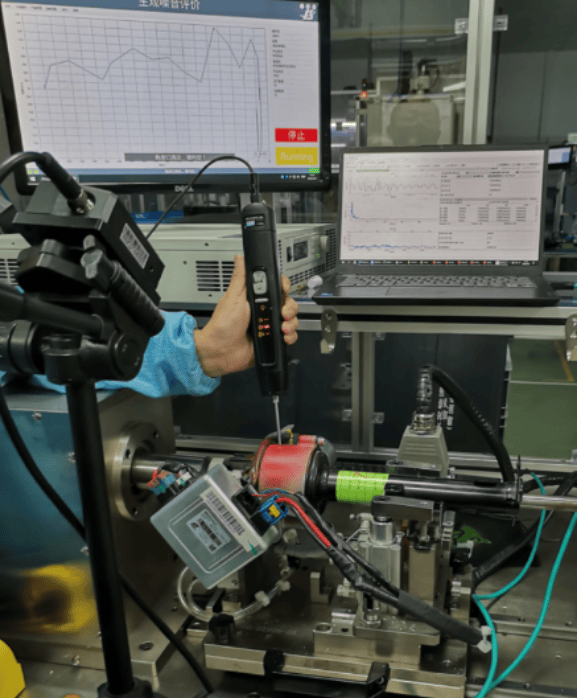

Electric Steering Shaft Vibration and Noise Detection

This case study demonstrates how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer revolutionizes electric steering shaft NVH testing. Through non-contact, automated vibration detection, manufacturers achieve 99% accuracy, faster inspection cycles, and consistent quality standards—enhancing automotive safety, comfort, and production efficiency.

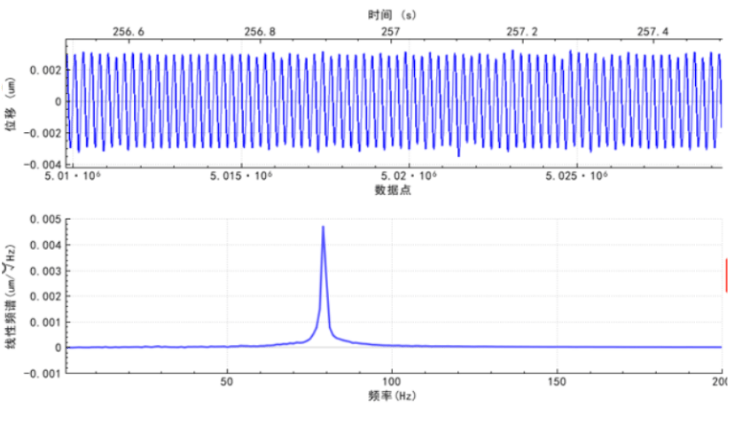

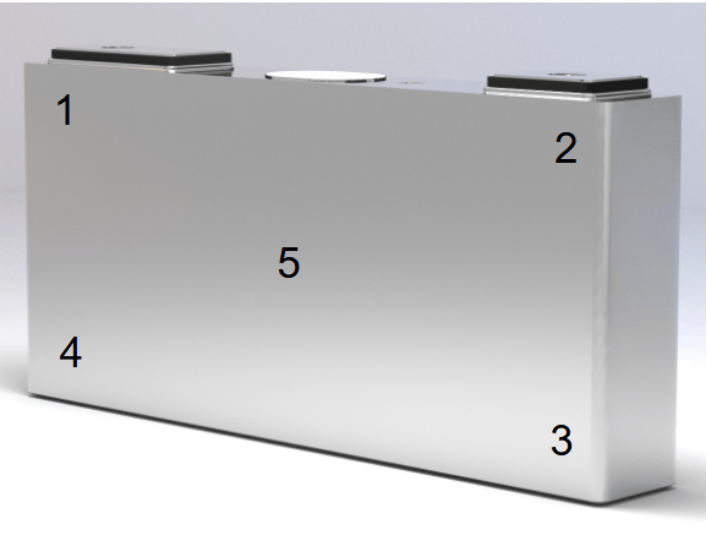

Vibration Frequency Response Testing of Power Battery Cells

This case study presents how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer delivers accurate, non-contact vibration frequency response testing for power battery cells. The method ensures structural reliability analysis, defect detection, and compliance with automotive battery vibration standards.

Real-Time Ultrasonic Welding Quality Monitoring Using VibroMicro

This technical case introduces Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer in real-time ultrasonic welding quality control for power battery electrode tabs. By directly measuring vibration energy, it enables intelligent, non-contact, and data-driven defect detection and process optimization.

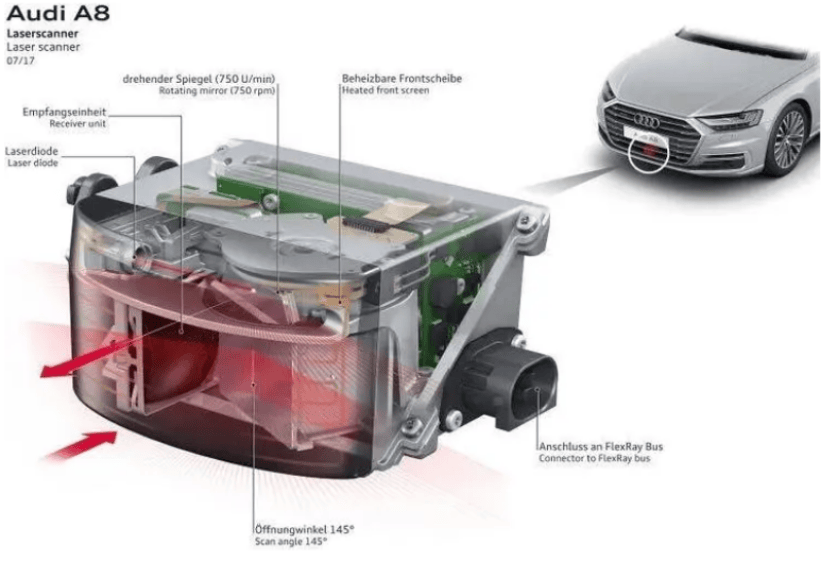

Vibration Measurement of Vehicle LiDAR with VibroMicro

This application case details how the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer enables precise, non-contact vibration measurement of vehicle LiDAR units during operation. The system detects micro-vibrations affecting optical stability, ensuring product quality and reliability in automotive production lines.

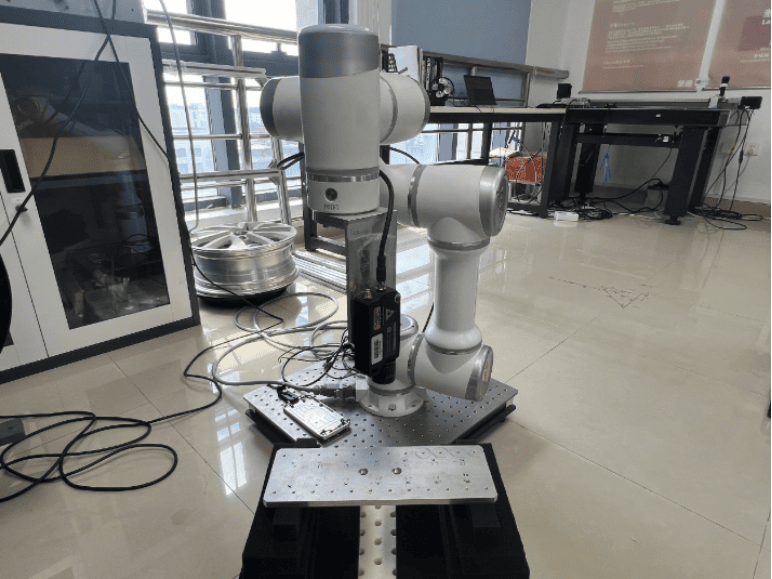

Automated Modal Analysis with Robotic Laser Vibrometry

This case study demonstrates how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer, integrated with a six-axis robot, automates modal testing and natural frequency measurement. The system delivers full-field mode shapes, high accuracy, and efficient data fusion for complex geometries and hard-to-reach structures.

Modal testing of Buick sub-frame structure

Buick Sub-frame Structure Modal Test

Modal tests determined the sub-frame’s vibration modes to optimize dynamic design, protecting the engine and reducing body vibrations.

Ruifeng commercial vehicle white body modal experiment

Ruifeng Commercial Vehicle White Body Modal Experiment

Jianghuai Automobile conducted modal tests to create a dynamic characteristics database for optimizing vehicle body performance.

SXQC body vibration testing at different speeds

SXQC Body Vibration Testing at Different Speeds

SXQC used the DE-944 dynamic signal analysis system and accelerometer to measure vibration signals from the engine, front axle, frame, and seat at varying speeds, identifying the cause of excessive downward vibration in heavy trucks and high-speed sports cars.

Suspension & Vibration Test of China Youth Passenger Car

Suspension Shock Absorption Performance Test & Structural Vibration Test of China Youth Car New Passenger Car

China Youth Automotive Company used the DE-944 dynamic signal test system and accelerometer to measure engine mount vibrations, testing suspension shock absorption performance to reduce excessive vibration near the vehicle's rear engine area.

Automotive airbag ECU installation reliability test

Automotive Airbag ECU Installation Reliability Test

This test examines the reliability of the acceleration signal transmission from the vehicle’s body structure to the ECU during a collision, ensuring the proper functioning of the airbag system’s center acceleration sensor and ECU integration.

Xihua University Frame Modal Analysis – Vehicle Research

Xihua University Frame Modal Analysis

By collecting and analyzing test data, modal frequencies, damping, and vibration modes of the frame were identified. This study provides a foundation for further research on vehicle vibration, noise, and structural optimization.

Planetary gearbox vibration and noise test

Vibration Noise Test of Planetary Gearbox

During the rotation test of a newly designed planetary gearbox, excessive vibration and noise were detected. Using the RE-846U rugged dynamic signal test system with acceleration sensors and sound transducers, the main vibration sources were identified, providing valuable data for structural optimization.