Electric Steering Shaft Vibration and Noise Detection

1. Project Background and Requirements

With the advancement of automotive electrification, Electric Power Steering (EPS) systems have become standard configuration. The NVH performance of the steering shaft directly impacts driving comfort and perceived quality. Traditional detection methods face significant challenges:

Subjective Judgment Issues: Manual auditory detection lacks objectivity and quantifiable standards

Health Hazards: Long-term exposure to industrial noise environments can cause hearing damage to inspectors

Low Efficiency: Individual testing is time-consuming, unable to meet the rhythm of high-speed production lines

Inconsistent Standards: Different inspectors may have varying judgment criteria, leading to inconsistent quality control

2. Testing Solution and System Configuration

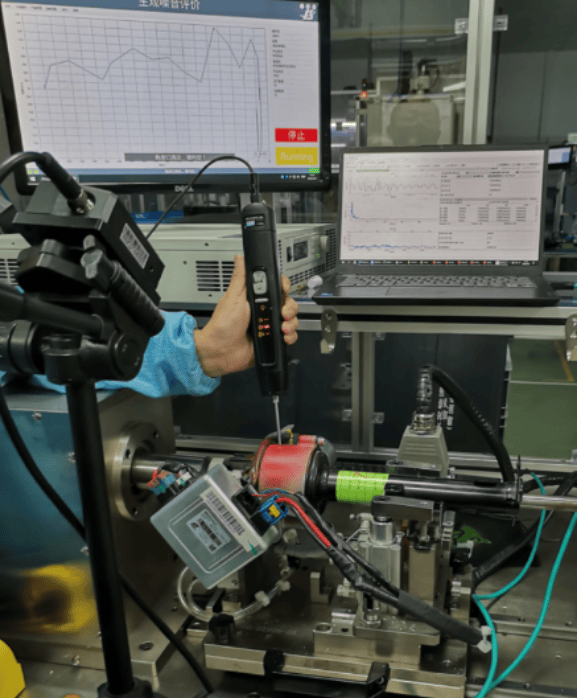

This solution employs non-contact laser vibration measurement technology to achieve fast, accurate detection of steering shaft vibration and noise characteristics.

System Composition:

Detection System:

Dynatronic VibroMicro VM-S-100 Micro Laser Doppler Vibrometer

Industrial-grade mounting bracket and protective housing

Excitation System:

Standardized test platform

Programmable motor driver

Signal Analysis System:

Real-time spectrum analysis software

Abnormal noise characteristic database

Automatic judgment algorithm

3. Test Procedure

Automatic Positioning:

The steering shaft is automatically transferred to the test station via conveyor

Laser automatically aligns with predetermined measurement points

Standardized Testing:

Drive the steering shaft motor to operate according to preset programs

Simulate various working conditions: startup, constant speed, acceleration/deceleration

Data Acquisition:

Laser vibrometer collects vibration velocity signals

Simultaneously acquire near-field acoustic signals (optional)

Automatic Analysis:

Real-time analysis of vibration spectrum characteristics

Compare with standard sample database

Automatically identify abnormal noise features

4. VibroMicro VM-S-100 Core Advantages

4.1 Non-Contact Measurement

Completely non-contact, avoiding any impact on rotating components

No additional load, accurately reflecting the true vibration state

Suitable for various surface materials and complex shapes

4.2 High Sensitivity

Nanometer-level displacement resolution

Capable of detecting weak vibration signals

Wide frequency range (DC-1MHz), covering the entire audible frequency range

4.3 Production Line Suitability

Compact size, easy for production line integration

Fixed installation, ensuring measurement consistency

High measurement speed, meeting production line cycle time requirements

4.4 Comprehensive Data

Provides complete vibration frequency and amplitude information

Can correlate vibration characteristics with acoustic signals

Establish quantifiable quality standards

5. Test Results and Application Value

5.1 Detection Content

Motor Vibration: Detect unbalanced vibration and electromagnetic noise

Gear Meshing: Identify gear wear and assembly defects

Bearing Status: Monitor bearing damage and lubrication issues

Structural Resonance: Discover structural design defects

5.2 Typical Abnormal Characteristics

Clear Frequency Peaks: Corresponding to specific fault frequencies

Broadband Noise: Typically caused by impact or friction

Frequency Modulation Phenomena: Often related to rotating component defects

Resonance Peaks: Indicating structural natural frequency issues

5.3 Application Benefits

Quality Improvement:

100% full inspection capability

Early detection of potential defects

Significant reduction in customer returns

Efficiency Enhancement:

Testing time reduced to within 10 seconds

No need for professional inspectors

Achieve true automated testing

Standardization Advancement:

Establish quantifiable quality standards

Data traceability for the entire process

Support continuous process improvement

6. Implementation Effectiveness

Performance Indicators:

Detection accuracy: >99%

False positive rate: <1%

Single testing time: <8 seconds

Continuous operation: >20 hours

Economic Benefits:

Reduce quality loss costs by approximately 60%

Save labor costs by about 80%

Decrease after-sales maintenance costs by approximately 40%

Conclusion:

The Dynatronic VibroMicro VM-S-100-based electric steering shaft abnormal noise detection system successfully replaces traditional manual auditory inspection methods. Through non-contact laser vibration measurement technology, it achieves quantitative, standardized, and automated quality control, significantly enhancing production efficiency and product quality while effectively protecting workers' occupational health. This solution provides an ideal quality assurance method for high-volume production in the automotive industry and can be extended to similar rotating component NVH testing scenarios.