Vibration Frequency Response Testing of Power Battery Cells

1. Project Background and Requirements

With the rapid development of new energy vehicles, the safety and reliability of power batteries have become core industry concerns. As the central unit of the battery system, the dynamic response of the cell's mechanical structure under vibration environments directly impacts battery life and safety. Traditional testing methods face the following pain points:

Limitations of Contact Measurement: Sensors like accelerometers introduce additional mass, altering the cell's inherent vibration characteristics.

Low Efficiency in Multi-Point Measurement: Requires repeated sensor placement, leading to cumbersome procedures.

Insufficient High-Frequency Response: Traditional sensors struggle to capture the cell's weak vibration modes at high frequencies (>1 kHz).

2. Test Solution and System Configuration

This solution employs non-contact laser vibrometry technology to analyze the dynamic characteristics of battery cells under vibration conditions through high-precision scanning.

System Composition:

Excitation System:

Electrodynamic shaker (supports frequency sweep range 1-2000 Hz, amplitude 1 mm)

Signal generator and power amplifier

Measurement System:

Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Multi-channel data acquisition module

Control and Analysis Software:

Vibration control and sweep signal generation

Real-time Frequency Response Function (FRF) calculation and modal analysis

Measurement Point Layout:

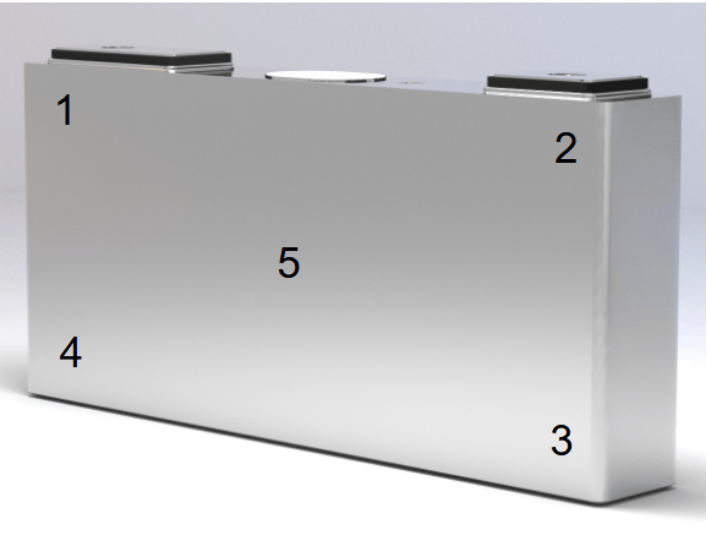

Five key locations on the cell surface (e.g., top center, side midpoint, corners) are selected for sequential scanning or simultaneous measurement (with multiple heads) using the laser vibrometer.

3. Test Procedure

Mounting and Fixation: Secure the cell onto the shaker using a fixture, ensuring no looseness.

Parameter Setting:

Sweep Range: 1-2000 Hz, linear or logarithmic sweep

Amplitude: 1 mm (adjustable according to standards)

Sweep Rate: 2-5 Hz/s (ensuring steady-state response)

Data Acquisition:

Align the laser vibrometer with each measurement point, collecting vibration velocity/displacement time-domain signals.

Simultaneously record the shaker input signal and the cell response signal.

Analysis Content:

Generate Frequency Response Function (FRF) curves and coherence functions.

Extract resonant frequencies, damping ratios, and mode shapes.

Analyze cell structural stiffness and potential defects (e.g., adhesive layer detachment, loose electrodes).

4. Core Advantages of VibroMicro VM-S-100

Non-Contact Measurement:

No mass-loading effect, accurately reflecting the cell's inherent vibration characteristics.

Avoids interference from contact sensor cables.

High Frequency Resolution:

Supports frequency response from DC to 25MHz levels, accurately capturing high-frequency modes.

Amplitude resolution down to the nanometer level, capable of identifying micro-vibrations.

Compact and Flexible:

Small footprint, easy integration into vibration test benches or automated production lines.

Can be adapted with robotic arms for automated multi-point scanning.

Multi-Parameter Output:

Simultaneously provides displacement, velocity, and acceleration data.

Directly generates Frequency Response Functions and modal parameters.

5. Test Results and Application Value

Typical Results:

Resonant Frequency Identification: Main resonance peaks identified in the 200-500 Hz and 800-1500 Hz ranges.

Mode Shape Visualization: Clear presentation of vibration modes such as bending and torsion.

Quality Assessment: Identification of defects like structural adhesive failure or electrode tab weak welding through shifts in resonant frequency or abnormal damping.

Application Value:

Quality Control: Rapid screening of cell structural consistency on the production line, rejecting defective products.

Design Verification: Provides data support for optimizing cell structure design and adhesive bonding processes.

Standards Compliance: Meets requirements of vibration test standards such as GB/T 31467.3 and UN 38.3.

6. Conclusion

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer provides a high-precision and high-efficiency solution for vibration testing of power battery cells. Through non-contact multi-point scanning, it not only significantly enhances test reliability but also offers deep insights for cell structural design and process improvement, contributing to higher safety and reliability standards in the new energy vehicle industry.