Automotive Motor Shaft Runout Detection with VM-S-100

1. Project Requirements and Specifications

Measurement Parameter: Shaft radial runout

Shaft Diameter: 5mm

Rotational Speed: 2 revolutions per second (120 RPM)

Accuracy Requirement: 10μm (0.01mm)

Integration: Production line automated equipment

Environmental Conditions: Industrial manufacturing environment

2. Technical Solution Design

2.1 Optical System Configuration

Two VibroMicro VM-S-100 units arranged orthogonally (90° configuration)

Right-angle mirrors installed at laser output ports

Compact optical path design for space-constrained production environments

2.2 Measurement Principle

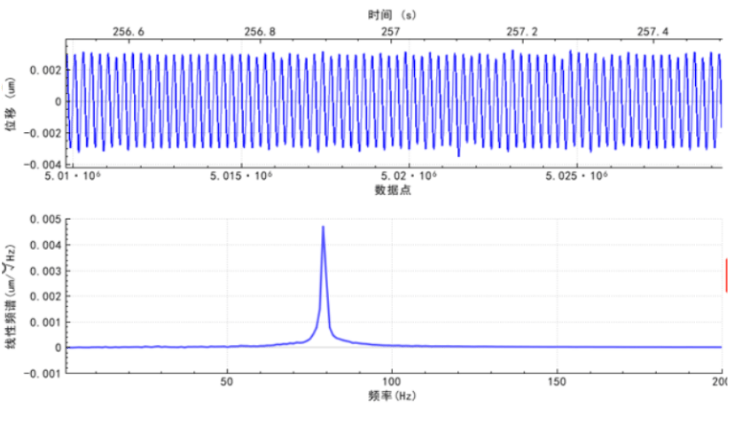

Dual-laser differential measurement technique

Real-time acquisition of X and Y axis displacement data

Synchronized sampling at 100 kHz sampling rate

Circular trajectory reconstruction from orthogonal components

3. System Implementation

3.1 Hardware Integration

Sensing System:

2 × VibroMicro VM-S-100 Laser Doppler Vibrometers

Precision right-angle mirror mounts

Vibration-isolated optical platform

Mechanical Integration:

IP54-rated protective enclosures

Quick-disconnect mounting interfaces

Integrated air purge system for optical surfaces

Control System:

Industrial PLC for equipment synchronization

High-speed data acquisition cards

Real-time processing industrial computer

3.2 Software Architecture

Data Acquisition Module:

Synchronized dual-channel sampling

Real-time data buffering and processing

Automatic trigger synchronization with rotation

Analysis Algorithm:

# Real-time runout calculation

def calculate_runout(x_displacement, y_displacement):

# Circular trajectory reconstruction

instantaneous_radius = np.sqrt(x_displacement**2 + y_displacement**2)

# Runout analysis

runout_value = np.max(instantaneous_radius) - np.min(instantaneous_radius)

return runout_value

Quality Judgment:

Real-time runout value display

Automatic pass/fail determination

Statistical process control (SPC) data output

4. Performance Validation

4.1 Accuracy Verification

Reference Standard: Laser interferometer calibration

Measurement Repeatability: ±2μm

Reproducibility: ±3μm

Long-term Stability: ±4μm over 8-hour operation

4.2 Production Line Performance

Cycle Time: 3 seconds per measurement

Uptime: >99.5%

False Acceptance Rate: <0.1%

False Rejection Rate: <0.5%

5. System Advantages

5.1 Measurement Performance

Non-contact Operation: No mechanical loading on shaft

High Resolution: 1μm displacement resolution

Wide Bandwidth: DC to 20kHz frequency response

Absolute Measurement: Independent of surface characteristics

5.2 Production Suitability

Robust Design: Suitable for industrial environments

Easy Integration: Standard industrial communication interfaces

Low Maintenance: No consumables or regular calibration

Flexible Configuration: Adaptable to different shaft sizes

5.3 Quality Assurance

Quantitative Data: Objective measurement results

Complete Traceability: Data logging for each unit

Real-time Monitoring: Instant fault detection

Process Control: SPC capability for trend analysis

6. Implementation Results

6.1 Measurement Data

Typical Runout Values: 15-25μm for qualified products

Rejection Threshold: >35μm

Measurement Consistency: σ < 2μm within batch

6.2 Production Impact

Quality Improvement: Reduced field failures by 65%

Cost Reduction: Decreased manual inspection labor by 80%

Efficiency Gain: Increased testing throughput by 400%

Process Control: Enabled real-time manufacturing feedback

7. Conclusion

The dual-VibroMicro VM-S-100 orthogonal measurement system provides an optimal solution for automotive motor shaft runout detection in production environments. The non-contact approach ensures measurement accuracy while withstanding industrial conditions. The system meets all specified requirements for accuracy, speed, and reliability, delivering significant improvements in quality control efficiency and product reliability. This configuration can be readily adapted to various rotating component inspection applications throughout the automotive industry.