Vibration Measurement of Vehicle LiDAR with VibroMicro

1. Background and Challenges

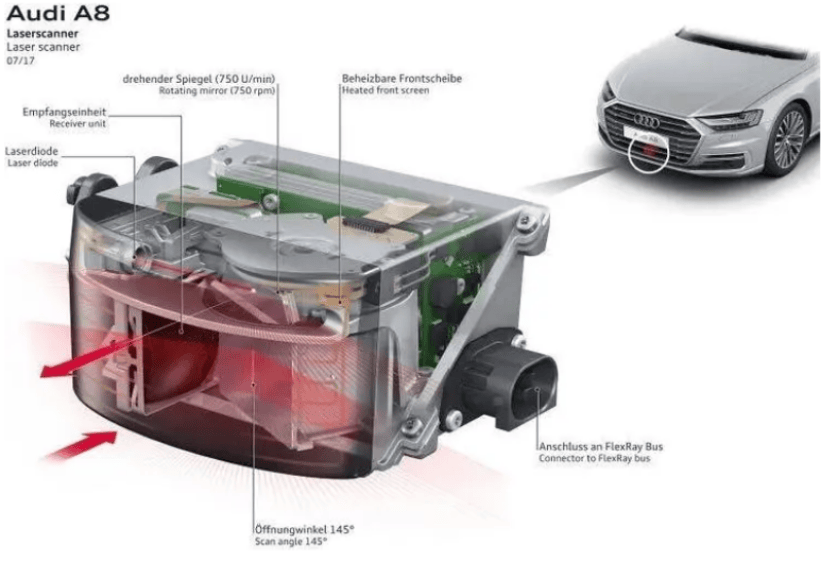

With the rapid development of autonomous driving technology, LiDAR (Light Detection and Ranging), as a core sensor, its performance stability is crucial for driving safety. During operation, internal scanning components (such as rotating mirrors/MEMS mirrors) generate vibrations that are transmitted to the housing. Excessive housing vibration can lead to:

Optical path deviation, reducing point cloud accuracy and resolution

Shortened lifespan of internal components

Potential loosening of mechanical connections

Traditional measurement challenges:

Contact sensors (accelerometers) alter the dynamic characteristics of lightweight LiDAR housing

Difficult to install sensors in compact spaces

Unable to perform measurements during actual operation on the production line

2. Solution: Non-Contact Vibration Monitoring System

The Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer provides an ideal non-contact measurement solution that can accurately monitor LiDAR housing vibration during actual operation.

System Configuration:

Core Sensor: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

Positioning System: Robotic arm or electric translation stage (for automated detection)

Signal Analysis: Spectral analysis software

Auxiliary Equipment: Vibration isolation platform, optical table

3. Test Method and Process

3.1 Measurement Setup

Fix the LiDAR on a vibration isolation platform

Align the laser beam perpendicular to key measurement areas:

Front window center

Motor/scanning module position

Housing corners and edges

Heat sink area

3.2 Test Procedure

Static Baseline Measurement:

Measure ambient vibration with LiDAR powered off

Record background noise spectrum

Dynamic Operation Measurement:

Start LiDAR in various operating modes:

Standby mode

Low-speed scanning mode

High-speed scanning mode

Maximum load mode

Real-time recording of vibration velocity/displacement data

Multi-point Scanning:

Automatically scan multiple critical points using robotic positioning

Generate vibration distribution cloud maps

4. Results and Analysis

4.1 Vibration Spectrum Characteristics

Characteristic Frequency Identification:

Motor rotation frequency and harmonics

Resonant frequencies of scanning mechanisms

Housing structural resonances

Typical Results:

Healthy LiDAR: Clean spectrum with distinct characteristic peaks

Defective LiDAR: Broadband noise, abnormal harmonics, or shifted resonant frequencies

4.2 Vibration Level Assessment

Qualification Standards:

Displacement amplitude: < 1 μm

Velocity RMS: < 0.5 mm/s

Acceleration: < 0.1 g

Defect Identification:

Unbalanced rotating components

Loose internal connections

Structural cracks or damage

Assembly quality issues

5. Core Advantages

5.1 Non-Contact Measurement

No mass loading effect

No modification to LiDAR structure

Suitable for various housing materials

5.2 High Precision

Nanometer-level displacement resolution

Wide frequency range (DC to 1 MHz)

High signal-to-noise ratio

5.3 Production Line Compatibility

Fast measurement speed (< 10 seconds per unit)

Easy integration with automated systems

Real-time quality monitoring

6. Application Value

6.1 Quality Control

100% online inspection capability

Early detection of manufacturing defects

Reduced product return rates

6.2 Process Optimization

Identify vibration sources

Optimize damping design

Improve structural stiffness

6.3 Reliability Verification

Validate product durability

Support design verification

Accelerate R&D cycles

7. Implementation Example

Test Object: Automotive-grade rotating mirror LiDAR

Measurement Points: 12 key positions

Test Duration: 8 seconds per LiDAR unit

Defect Detection Rate: > 95%

False Positive Rate: < 2%

Conclusion:

The Dynatronic VibroMicro VM-S-100-based vibration monitoring system provides automotive LiDAR manufacturers with an efficient and accurate quality control solution. By enabling non-contact vibration measurement during actual operation, it effectively ensures product performance and reliability while significantly improving production efficiency. This solution is particularly valuable for high-volume production environments where quality consistency is paramount.