Automotive Seat Vibration Testing with VM-S-100

This application case highlights how Dynatronic’s VM-S-100 Laser Doppler Vibrometer helped an automotive seat manufacturer identify the resonant frequency and vibration amplitude of a headrest bracket. The non-contact test delivered accurate, high-resolution NVH insights without altering the structure’s dynamic behavior.

Automotive Motor Shaft Runout Detection with VM-S-100

This case study presents how Dynatronic’s dual VibroMicro VM-S-100 Laser Doppler Vibrometer system enables real-time, non-contact shaft runout detection for automotive motors. With ±2μm repeatability, high-speed integration, and SPC capability, it delivers precise, automated quality control in demanding industrial environments.

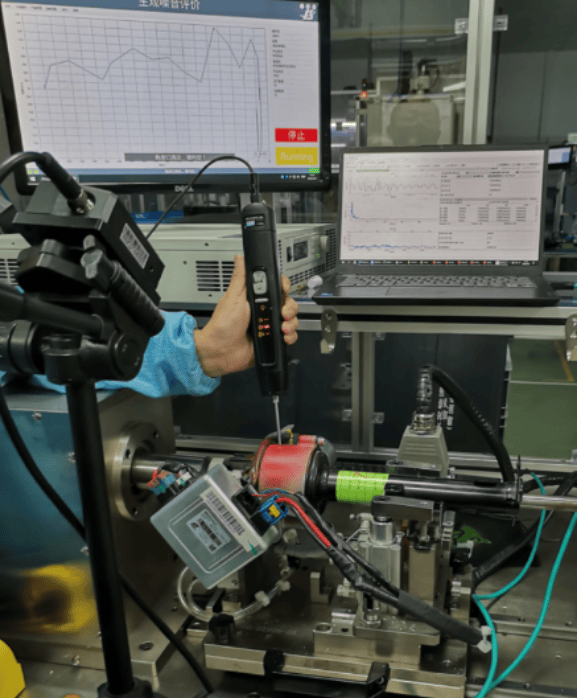

Electric Steering Shaft Vibration and Noise Detection

This case study demonstrates how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer revolutionizes electric steering shaft NVH testing. Through non-contact, automated vibration detection, manufacturers achieve 99% accuracy, faster inspection cycles, and consistent quality standards—enhancing automotive safety, comfort, and production efficiency.

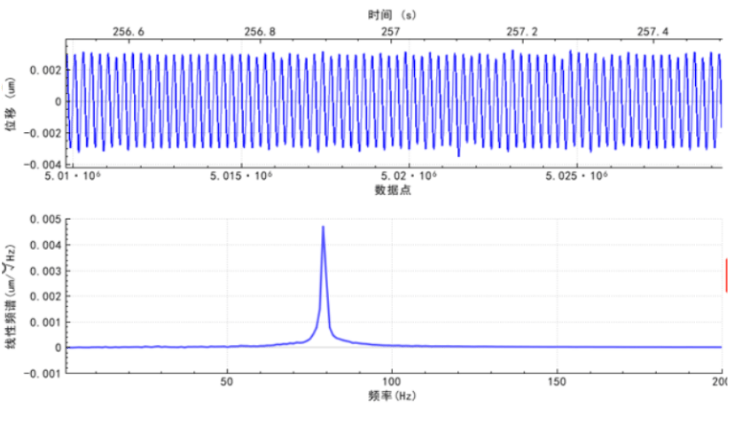

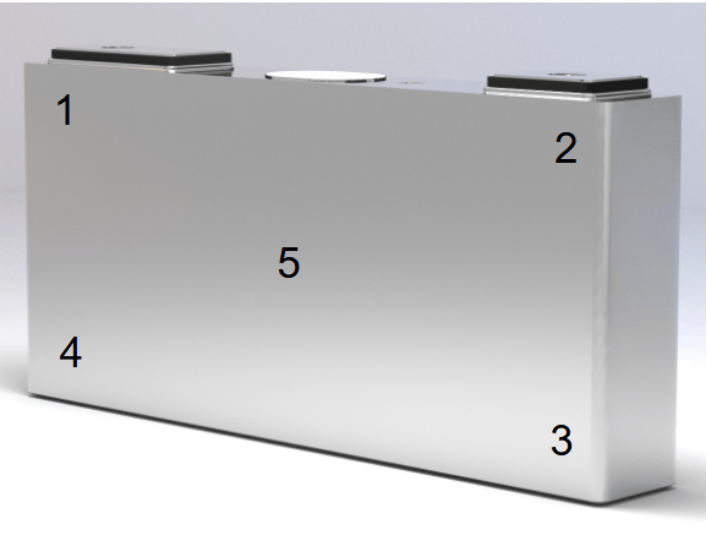

Vibration Frequency Response Testing of Power Battery Cells

This case study presents how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer delivers accurate, non-contact vibration frequency response testing for power battery cells. The method ensures structural reliability analysis, defect detection, and compliance with automotive battery vibration standards.

Real-Time Ultrasonic Welding Quality Monitoring Using VibroMicro

This technical case introduces Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer in real-time ultrasonic welding quality control for power battery electrode tabs. By directly measuring vibration energy, it enables intelligent, non-contact, and data-driven defect detection and process optimization.

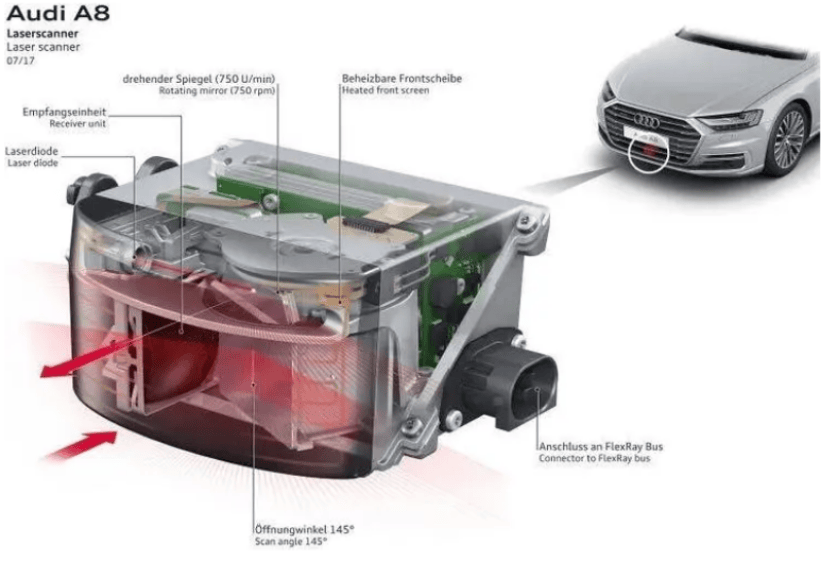

Vibration Measurement of Vehicle LiDAR with VibroMicro

This application case details how the Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer enables precise, non-contact vibration measurement of vehicle LiDAR units during operation. The system detects micro-vibrations affecting optical stability, ensuring product quality and reliability in automotive production lines.

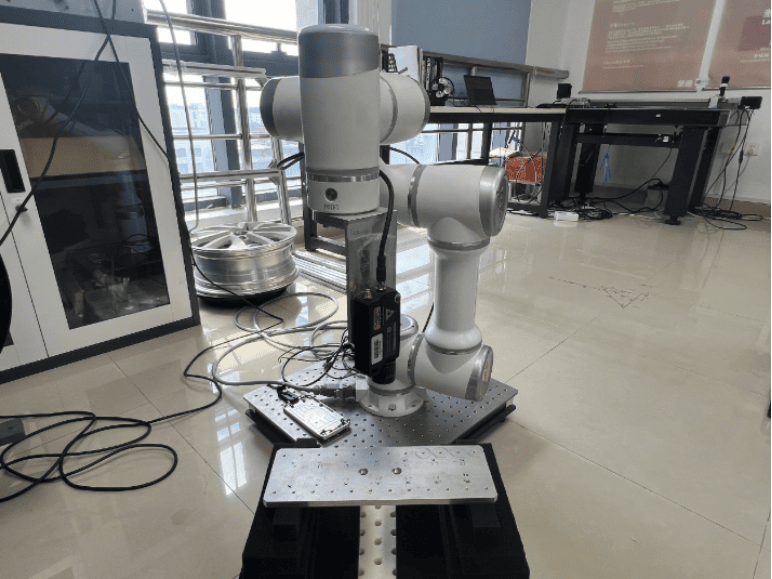

Automated Modal Analysis with Robotic Laser Vibrometry

This case study demonstrates how Dynatronic’s VibroMicro VM-S-100 Laser Doppler Vibrometer, integrated with a six-axis robot, automates modal testing and natural frequency measurement. The system delivers full-field mode shapes, high accuracy, and efficient data fusion for complex geometries and hard-to-reach structures.