State Grid Cable Aeolian Vibration Testing with VM-S-100

Application: Aeolian Vibration Monitoring of Overhead Power Transmission Lines

Solution: Dynatronic VibroMicro VM-S-100 Laser Doppler Vibrometer

1. Executive Summary

State Grid required a more efficient and reliable method for monitoring aeolian vibration on high-voltage transmission cables. These high-frequency, low-amplitude vibrations, induced by wind, can lead to conductor fatigue and failure. The Dynatronic VibroMicro VM-S-100 was deployed to replace traditional contact accelerometers, offering a non-contact solution with a visible red laser for easy targeting and analog output for direct data acquisition, significantly improving the accuracy and practicality of field measurements.

2. The Challenge: Limitations of Contact Sensors

Traditional methods for measuring cable vibration rely on installing contact accelerometers directly onto the conductor. This approach presents several challenges:

Mass-Loading Effect: The sensor's weight alters the cable's natural dynamic properties, leading to inaccurate vibration data.

Complex Installation: Installation requires de-energizing the line or using complex hot-line work procedures, posing safety risks and being time-consuming.

Long-Term Reliability: Sensors and their cables are exposed to harsh environmental conditions, leading to potential degradation and failure.

3. The Solution: Non-Contact Laser Vibration Measurement

The Dynatronic VibroMicro VM-S-100 provides a superior alternative with its advanced features tailored for this application:

Replaces Contact Accelerometers: The core advantage is eliminating the mass-loading effect and complex installation, providing a true measurement of the cable's vibration.

Visible Red Laser Indicator: Allows operators to precisely and visually target the specific measurement point on the conductor from a safe distance on the ground, ensuring accurate and repeatable data collection.

Analog Output: Provides a real-time, high-fidelity voltage signal directly proportional to vibration velocity. This allows for seamless integration with existing data acquisition systems used for long-term monitoring.

4. Test Setup & Procedure

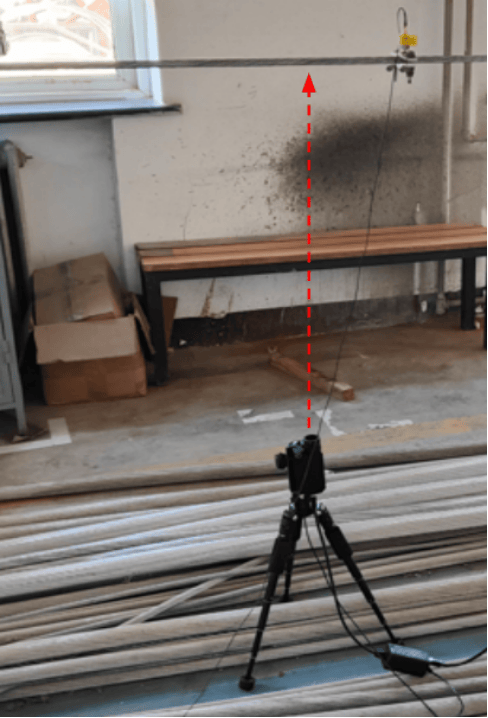

Targeting: The VM-S-100 unit is set up at a safe distance from the power line. The highly visible red laser spot is aimed at the target cable.

Data Acquisition: The analog output signal from the vibrometer is connected directly to a portable data acquisition system or a permanent SCADA system.

Monitoring: Vibration velocity data is recorded over time to analyze the frequency and amplitude of the aeolian vibrations.

5. Results & Benefits

The implementation of the VM-S-100 system delivered immediate and significant benefits:

Enhanced Data Accuracy: By eliminating mass-loading, the measured vibration frequencies and amplitudes accurately reflect the true behavior of the conductor.

Improved Operational Safety: Measurements can be performed from a safe, remote location without the need for direct contact with energized lines.

Increased Efficiency: Setup and targeting are rapid and straightforward, drastically reducing survey time and costs.

Superior Reliability: The non-contact method and robust design ensure consistent performance in outdoor environments.

6. Conclusion

The Dynatronic VibroMicro VM-S-100 has proven to be an ideal solution for power utility companies like State Grid. It successfully replaces outdated contact-sensor methods for monitoring aeolian vibration on transmission lines. The combination of non-contact measurement, a visible laser for easy targeting, and analog output provides a safer, more accurate, and highly reliable system for ensuring the integrity and longevity of critical power infrastructure.