VibroMicro Laser Vibrometer for Frequency Testing

VibroMicro Laser Vibrometer Non-Contact Testing System

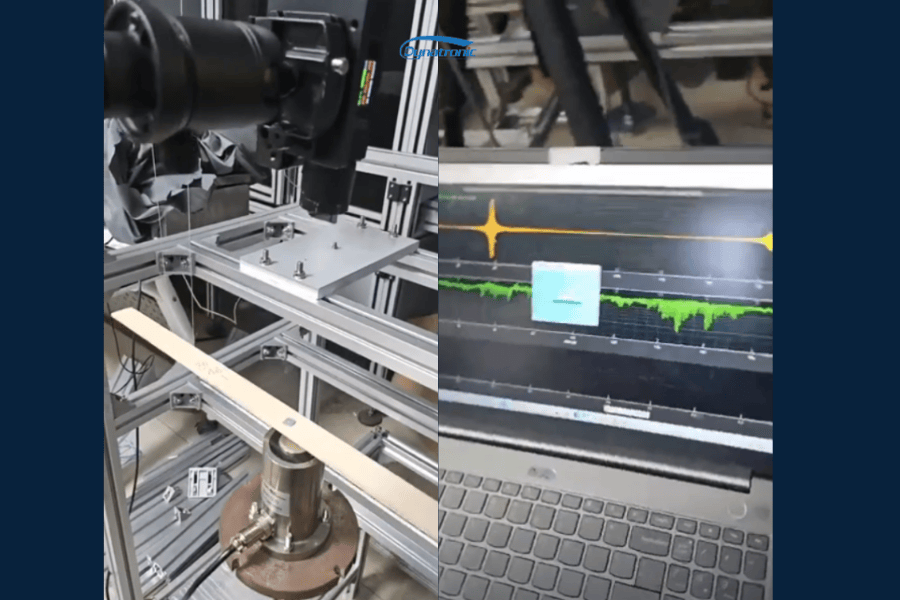

——Integrated Non-Contact Excitation Solution for Natural Frequency Testing

Natural frequency testing is fundamental to structural dynamics analysis, especially in high-precision fields like aerospace, biomedical engineering, and MEMS development. The VibroMicro Laser Vibrometer Non-Contact Testing System by Dynatronic combines laser measurement and contactless excitation in a fully integrated platform. This article presents the system’s components, testing principles, and technical advantages for accurate and efficient modal analysis.

1. System Components

VibroMicro Laser Vibrometer

Measurement range: DC–25MHz

Displacement resolution: 0.001nm

Supports 1D vibration measurement (X/Y/Z-axis acquisition)

Non-Contact Excitation System

Types: Acoustic/electromagnetic/air-bearing exciters

Frequency range: DC–10kHz

Maximum excitation force: 20N (customizable)

Intelligent Control Platform

Frequency sweep range: 0.1Hz–500kHz

Sweep modes: Linear/logarithmic/custom

Real-time FFT analysis

2. Testing Principle

A "non-contact excitation & non-contact measurement" closed-loop system:

Wideband excitation via acoustic/magnetic fields

Real-time structural response capture using laser vibrometer

Automatic resonance peak detection (±0.01Hz sensitivity)

Frequency Response Function (FRF) curve generation

3. Technical Advantages

| Feature | Traditional Methods | This Solution |

|---|---|---|

| Excitation Method | Contact (impact hammer/shaker) | Fully non-contact |

| Added Mass | Affects modal characteristics | Zero added mass |

| Applicable Scenarios | Lab environments | Harsh conditions (high temp/vacuum, etc.) |

4. Standard Testing Procedure

Pre-Test Setup

Laser positioning (auto-focus accuracy: ±2μm)

Exciter parameter configuration (frequency/amplitude/sweep rate)

Automated Frequency Sweep Test

Step precision: 0.001Hz

Maximum sampling rate: 256kHz

Modal Analysis

Automatic identification of first 10 natural frequencies

Vibration mode animation (4K output supported)

5. Application Cases

Case 1: Surgical Blade Modal Testing

Test object: Titanium alloy ultrasonic blade (15mm length)

Results:

1st bending mode: 28.5kHz

2nd torsional mode: 67.3kHz

Damping ratio: 0.0021 (ambient air)

Case 2: Precision MEMS Testing

Achieved 0.1Hz resolution testing on 2mg microstructures

Identified unexpected 12.7kHz resonance due to design error

The VibroMicro Laser Vibrometer Non-Contact Testing System offers a fully integrated solution for high-precision natural frequency testing—eliminating the drawbacks of traditional contact methods. Its ability to excite and measure structures without physical interference enables accurate modal analysis across a wide range of test objects, from delicate surgical blades to micro-scale MEMS components. With high resolution, automated workflows, and robust environmental adaptability, VibroMicro empowers engineers and researchers to confidently validate designs, detect structural anomalies, and ensure optimal performance under real-world conditions.