Magnetoelectric Velocity Sensors for Vibration Monitoring

The Magnetoelectric Velocity Sensor is a robust vibration measurement device designed to directly measure vibration velocity, one of the most widely used indicators for evaluating machine condition and vibration severity. Velocity measurement is particularly effective for assessing mechanical health, as it correlates closely with fatigue, wear, and overall mechanical energy within rotating and structural systems.

Magnetoelectric velocity sensors operate on an electromagnetic induction principle rather than piezoelectric technology. This makes them especially suitable for low-frequency vibration measurement, where velocity-based evaluation provides clearer and more meaningful results than acceleration alone. Because of their stable output and predictable behavior, these sensors are widely used in industrial condition monitoring, acceptance testing, and long-term vibration surveillance.

Operating Principle

The sensor consists of a suspended coil or conductor moving within a magnetic field. When vibration occurs, the relative motion between the magnetic field and the conductor induces an electrical voltage proportional to the vibration velocity. This direct velocity output eliminates the need for signal integration, reducing signal drift and improving accuracy at low frequencies.

Unlike acceleration-based measurements that require mathematical processing to derive velocity, magnetoelectric velocity sensors provide a true velocity signal, making them especially effective for machine health evaluation and compliance with vibration severity standards.

Key Characteristics

Magnetoelectric velocity sensors offer excellent stability, strong low-frequency response, and high repeatability over long operating periods. They are inherently rugged and capable of continuous operation in industrial environments where temperature variation, mechanical stress, and background vibration are present.

Their linear response and low noise characteristics make them suitable for both periodic inspections and permanent monitoring installations. The mechanical design ensures consistent performance with minimal maintenance, which is particularly valuable in industrial plants and infrastructure monitoring applications.

Typical Applications

Magnetoelectric velocity sensors are commonly used in:

Machinery Condition Monitoring: Evaluating vibration severity in motors, pumps, fans, compressors, and gearboxes

Predictive Maintenance: Identifying early signs of imbalance, misalignment, looseness, or bearing wear

Industrial Acceptance Testing: Verifying vibration limits during commissioning and factory acceptance tests

Structural Vibration Measurement: Monitoring vibration behavior in frames, foundations, and mechanical supports

Power & Energy Systems: Assessing vibration levels in turbines, generators, and auxiliary equipment

Velocity measurement is often preferred in these applications because it provides a direct and intuitive indication of mechanical stress and system health.

Integration with Measurement Systems

The magnetoelectric velocity sensor is designed for seamless integration with Dynatronic data acquisition and monitoring systems. When combined with vibration controllers, monitoring hardware, and analysis software, engineers can correlate velocity data with acceleration, displacement, temperature, or operational parameters. This multi-parameter approach enables deeper insight into system behavior and supports informed maintenance and engineering decisions.

Practical and Reliable Vibration Insight

By delivering direct velocity measurement with strong low-frequency performance and long-term stability, magnetoelectric velocity sensors remain a trusted solution for industrial vibration monitoring. Their simplicity, durability, and clarity of output make them an essential tool for engineers focused on machine reliability, safety, and performance.

|

|

|||||||

|---|---|---|---|---|---|---|---|---|

| Type Number | DT2D001 | DT2D001A | ||||||

| Sensitivity | 0.3V/m·s⁻² | 20V/m·s⁻¹ | 5V/m·s⁻¹ | 0.3V/m·s⁻¹ | 0.3V/m·s⁻² | 20V/m·s⁻¹ | 5V/m·s⁻¹ | 0.3V/m·s⁻¹ |

| Range | 20m·s⁻² | 0.125m·s⁻¹ | 0.3m·s⁻¹ | 0.6m·s⁻¹ | 20m·s⁻² | 0.125m·s⁻¹ | 0.3m·s⁻¹ | 0.6m·s⁻¹ |

| Frequency Response (±10%) | 0.5 ~ 40Hz | 4 ~ 50Hz | 1 ~ 50Hz | 0.5 ~ 50Hz | 0.5 ~ 40Hz | 4 ~ 50Hz | 1 ~ 50Hz | 0.5 ~ 50Hz |

| Frequency Response (-3 ~ +1dB) | 0.25 ~ 100Hz | 0.5 ~ 100Hz | 1 ~ 100Hz | 0.17 ~ 80Hz | 0.25 ~ 100Hz | 1 ~ 100Hz | 0.5 ~ 100Hz | 0.17 ~ 80Hz |

| Gear | 0 | 1 | 2 | 3 | 0 | 1 | 2 | 3 |

| Operating Temperature | -10ºC ~ +60ºC | -10ºC ~ +60ºC | ||||||

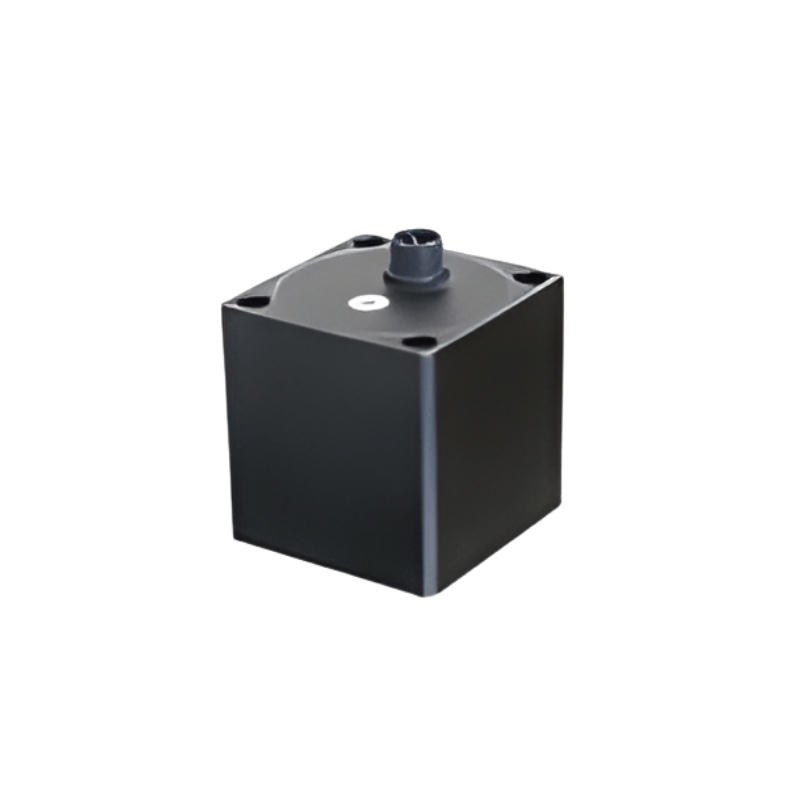

| Size | 63X63X63mm | 63X63X63mm | ||||||

| Weight | 800g | 800g | ||||||

|

|

||||

|---|---|---|---|---|---|

| Type Number | DT2D002 | DT2D004 | |||

| Sensitivity | 20V/m·s⁻¹ | 0.3V/m·s⁻² | 20V/m·s⁻¹ | 5V/m·s⁻¹ | 0.25V/m·s⁻¹ |

| Range | 0.5m·s⁻² | 20m·s⁻² | 0.125m·s⁻¹ | 0.3m·s⁻¹ | 0.6m·s⁻¹ |

| Frequency Response (±10%) | 16 ~ 1000Hz | 0.5 ~ 40Hz | 4 ~ 50Hz | 1 ~ 50Hz | 0.5 ~ 50Hz |

| Frequency Response (-3 ~ +1dB) | 10 ~ 1000Hz | 0.25 ~ 100Hz | 1 ~ 100Hz | 0.5 ~ 100Hz | 0.05 ~ 50Hz |

| Gear | - | 0 | 1 | 2 | 3 |

| Operating Temperature | -10ºC ~ +60ºC | -10ºC ~ +60ºC | |||

| Size | 38X38X70mm | 63X63X63mm | |||

| Weight | 260g | 800g | |||