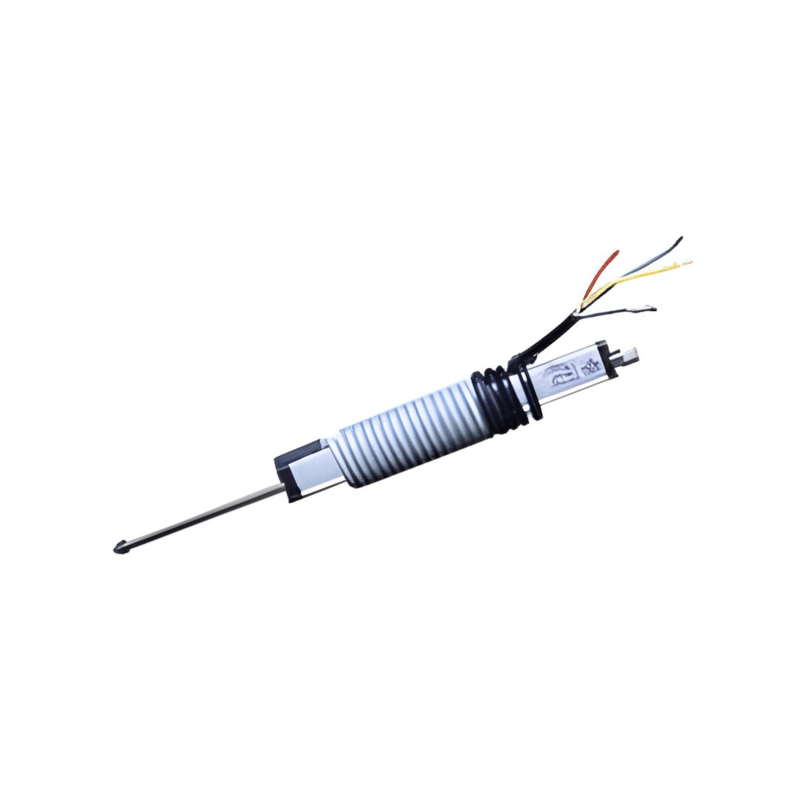

Linear Displacement Sensors for Precise Position Measurement

The Linear Displacement Sensor is a precision measurement device designed to accurately measure linear position, movement, or displacement of an object along a single axis. Linear displacement measurement is a critical parameter in many industrial, laboratory, and research applications, as it provides direct insight into mechanical motion, deformation, and positional accuracy.

Linear displacement sensors convert physical movement into an electrical signal that is proportional to the distance traveled. This allows engineers to monitor motion in real time, validate mechanical performance, and analyze system behavior under static or dynamic conditions. Depending on the sensing technology used—such as inductive, potentiometric, or transformer-based principles—these sensors can deliver high resolution, excellent repeatability, and long-term stability.

Measurement Principle

In a typical linear displacement sensor, the movement of a core, slider, or target causes a change in an electrical parameter such as inductance, resistance, or voltage. This change is then processed into a continuous output signal that represents displacement with high accuracy. Because the measurement is purely linear, the output is intuitive and easy to interpret for both control and analysis purposes.

Linear displacement sensors are particularly effective for applications where contact or non-contact position feedback is required, and where precise tracking of small movements is essential.

Key Characteristics

Linear displacement sensors offer high resolution, good linearity, and low hysteresis, ensuring reliable measurements over repeated cycles. They are available in various stroke lengths to support both short-range precision measurements and longer travel distances. Compact mechanical designs allow easy installation in test rigs, machines, and structures where space may be limited.

The robust construction of these sensors ensures stable performance even in environments subject to vibration, temperature variation, or continuous operation. Their predictable output makes them suitable for both real-time monitoring and closed-loop control applications.

Typical Applications

Linear displacement sensors are widely used across many industries, including:

Mechanical Testing: Measuring deformation, elongation, or compression of materials and components

Industrial Automation: Position feedback in actuators, presses, and motion systems

Automotive & Transportation: Suspension testing, component travel measurement, and structural evaluation

Aerospace & Defense: Monitoring actuator movement and structural displacement

Research & Education: Experimental studies involving motion, deflection, and mechanical behavior

In these applications, accurate displacement data is essential for validating designs, ensuring quality, and improving system reliability.

Integration with Measurement Systems

Linear displacement sensors are designed for seamless integration with Dynatronic data acquisition and monitoring systems. When synchronized with parameters such as force, strain, vibration, or temperature, displacement data provides deeper insight into how systems respond to load, motion, and environmental influences. This multi-parameter measurement approach supports more comprehensive analysis and better-informed engineering decisions.

Reliable Position Measurement for Critical Applications

By delivering accurate, stable, and repeatable linear position measurements, linear displacement sensors play a key role in modern testing and monitoring systems. Their versatility, robustness, and ease of integration make them an essential tool for engineers who require confidence in every displacement measurement they record.

| Type Number | DT5G101 | DT5G102 | DT5G103 | DT5G104 | DT5G105 | DT5G106 | DT5G107 |

|---|---|---|---|---|---|---|---|

| Sensitivity | 2mV/mm@2V | 0.8mV/mm@2V | 0.4mV/mm@2V | 0.27mV/mm@2V | 0.2mV/mm@2V | 0.2mV/mm@2V | 0.07mV/mm@2V |

| Valid Itinerary | 10mm | 25mm | 50mm | 75mm | 100mm | 200mm | 300mm |

| Size A | 21mm | 33mm | 67mm | 98mm | 130mm | 254mm | 395mm |

| Size B | 41mm | 56mm | 81mm | 106mm | 131mm | 231mm | 331mm |